Fntroduction

Gear transmission is the most widely used transmission method in many mechanical devices, so the impact of gear failure is also significant. In practical production, gear modification can effectively improve the strength of gears and increase their service life. Scholars at home and abroad have done a lot of research on tooth profile modification. Any tooth profile modification method will cause changes in the balance of the tooth profile due to the deformation of the gear contact under load, and propose new balance conditions. Gear transmission is a dynamic process, and the deformation and errors generated during this process will inevitably change with gear modification, thus changing the dynamic characteristics of the meshing transmission process. Therefore, in order to ensure the effectiveness of gear modification methods, it is necessary to conduct dynamic analysis of gear meshing. Research on the dynamic performance and modification of gears, based on different modification methods, has been conducted to obtain the dynamic stress variation diagram before and after modification, providing an effective basis for gear dynamics analysis. Using ANSYS software to establish a gear meshing pair, analyze the stress distribution before and after modification, and prove that tooth profile modification can improve gear strength. A new tooth profile drum method is developed, which involves slightly drumming the tooth profile from the root and tip to the pitch circle position in the direction of the tooth profile, forming a new tooth profile. Based on this tooth profile drum method, an involute gear tooth profile drum mathematical model is established, and a three-dimensional model is created using UG. The transient dynamics module in ANSYS Workbench is used to analyze the stress and strain during the gear contact meshing process, and the Fatigue Tool module in Workbench is used to predict and compare the lifespan of the gear before and after modification, verifying the effectiveness of the modification method.

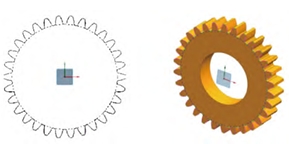

Establishment of the Mathematical Model for the Drum-Shaped Gear Tooth Profile

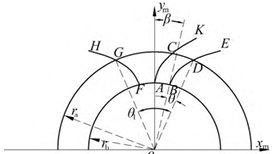

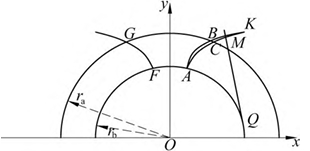

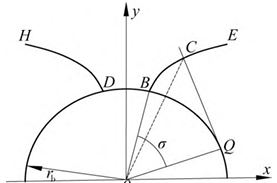

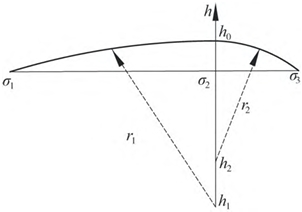

On a plane, during the process of a moving straight line (occurrence line) rolling along a fixed circle (base circle), the trajectory of any point on this line is an involute of the base circle. If the radius of the base circle is rb, and a rectangular coordinate system is established with the center of the base circle as the origin, then the parametric equation of the involute in the rectangular coordinate system is where σ is the angle between the fixed point and the line connecting the center of the circle and the x-axis, and is the sum of the angle of development and the pressure angle of the involute.

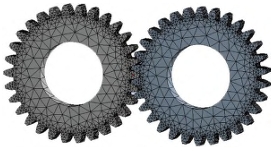

Through transient dynamic analysis of the drum gear pair and standard gear pair, the equivalent stress cloud map and equivalent strain cloud map during the gear meshing process are obtained. It can be seen that the maximum equivalent stress distribution during the meshing process is mainly concentrated on the gear pitch line and the gear root, which is consistent with the actual situation. The stress concentration at the root of the gear will lead to cracks and fractures at the root of the gear. When the safety factor is taken as 1.2, the allowable stress σ [ ] = 654 MPa, the maximum stress on the gear is less than the allowable stress, meeting the strength requirements. And the maximum stress and strain of the circular drum gear are the smallest among the three gear pairs, while the parabolic drum gear is slightly larger, and the standard gear has the largest maximum stress and strain.

Epilogue

1) This article uses Workbench and Fatigue Tool to model the fatigue and predict the life of a 40Cr material spur gear.

2) According to the gear tooth modification method proposed in this article, the stress and strain concentration locations of the modified gear remain unchanged and are still concentrated on the pitch line of the gear

And the tooth root, and it does not exceed the allowable stress, which meets the actual standard.

3) The research shows that the fatigue life of the round drum gear is higher than that of the parabolic drum gear, and both are higher than the standard gear. The research method provides a reference optimization design method for improving gear performance.