This article delves deep into the fault prediction and analysis of standard gear reducers, a crucial component in various industrial machinery. By leveraging advanced techniques such as vibration signal analysis, variational mode decomposition, and self – attention networks, a comprehensive fault prediction model is developed. Through detailed experimental data and in – depth analysis, the effectiveness of the proposed model is demonstrated, providing valuable insights for industrial equipment maintenance and management.

1. Introduction

1.1 Importance of Gear Reducers in Industry

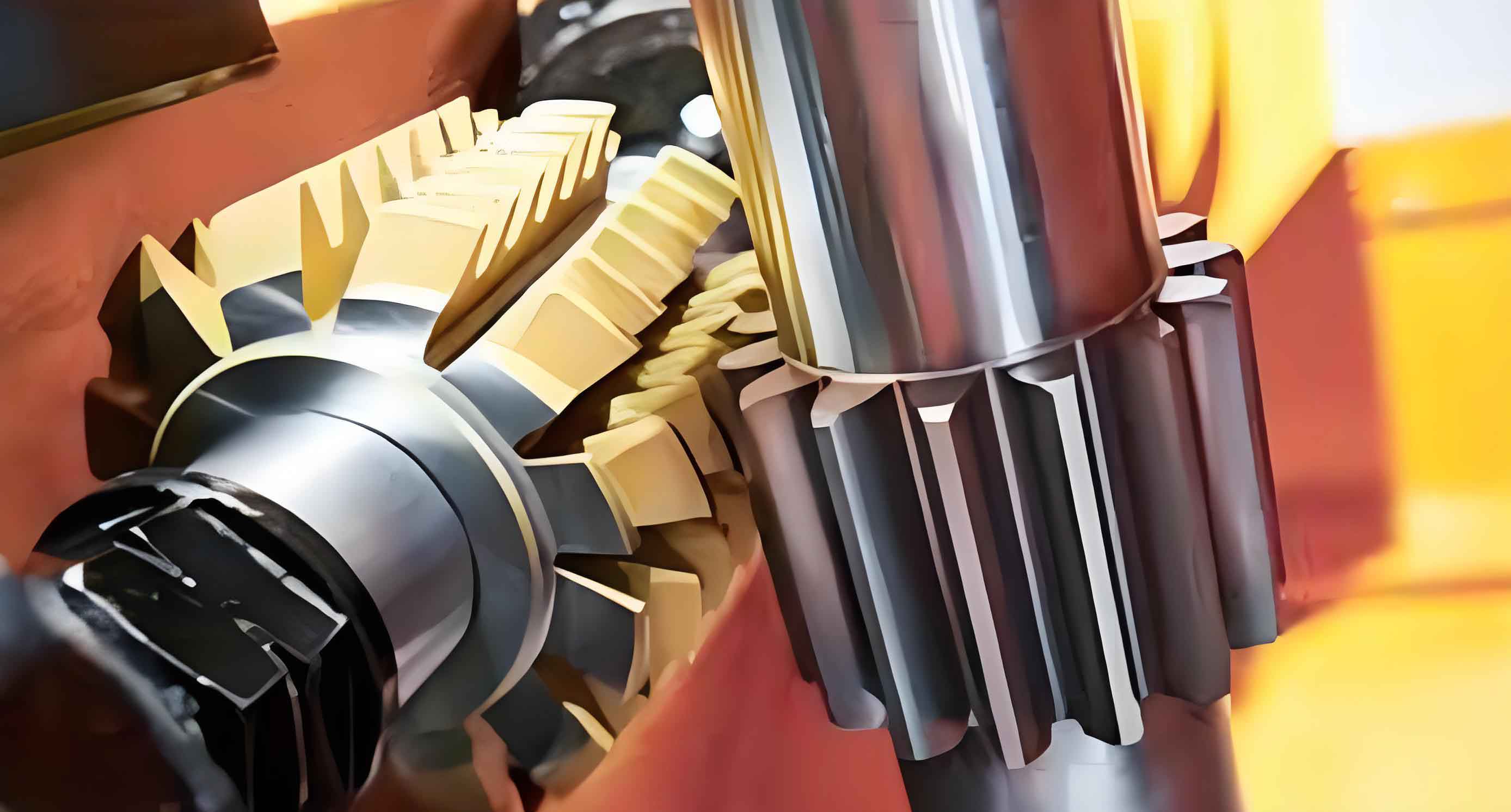

Gear reducers are widely used in numerous industrial applications, such as in manufacturing plants, power generation facilities, and transportation systems. In a pharmaceutical production line, for example, the standard gear reducer is a key part of the agitator in the main reactor. Its proper functioning is essential for the smooth operation of the entire production process. Any malfunction can lead to significant losses, including unplanned downtime of the production line, resulting in equipment idle time and waste of chemical materials. Table 1 summarizes the potential impacts of gear reducer failures in different industries.

| Industry | Impact of Gear Reducer Failure |

|---|---|

| Manufacturing | Production halt, increased production costs, and potential damage to products |

| Power Generation | Interruption of power supply, affecting grid stability and increasing maintenance costs |

| Transportation | Vehicle breakdown, safety risks, and disruption of transportation services |

1.2 Limitations of Traditional Fault Prediction Methods

Traditional machine – learning algorithms like SVM, RF, and GBDT face challenges when dealing with high – dimensional and non – linear data. Some methods, such as the PCA – based anomaly detection method, may not fully consider the time – series relationships in data. CNN networks often overlook the sequential nature of time – series data, leading to inaccurate predictions. Table 2 compares the limitations of different traditional methods.

| Method | Limitation |

|---|---|

| SVM | Poor performance in high – dimensional non – linear data |

| RF | Struggles with complex data patterns and may overfit |

| GBDT | Sensitive to outliers and has limitations in handling large – scale data |

| PCA – based methods | Inadequate consideration of time – series relationships |

| CNN networks | Inability to capture sequential information in time – series data |

2. Fault Mixing Prediction Model

2.1 Model Structure

The proposed fault prediction model combines the bearing operation mechanism model and small – sample analysis methods. As shown in Figure 1, the model first processes the sensor – monitored data. Since the collected vibration time – domain signals contain a large amount of noise, the mechanism model of the equipment is used to convert the signals into six features, including skewness, margin, and peak – to – peak value. Then, through VMD decomposition, the time – domain signals are transformed into frequency – amplitude signals. After that, the same self – attention mechanism is applied to extract features from different types of data. Finally, the data is processed by the twin network and meta – learning ideas to enhance data diversity and optimize the network through backpropagation.

[Insert Figure 1: Overall Network Structure Diagram]

2.2 Feature Extraction

Six key features are extracted from the vibration signals based on the vibration equipment mechanism model. Table 3 lists these features and their formulas (in a simplified form without complex mathematical notations).

| Feature | Formula (Simplified) |

|---|---|

| Margin | Ratio of maximum absolute value to root – mean – square value of vibration signal |

| Peak – to – Peak Value | Sum of the absolute maximum and minimum values of the vibration signal |

| Waveform Index | Ratio of root – mean – square value to mean absolute value of the vibration signal |

| Pulse Index | Related to the ratio of maximum value to mean absolute value of the vibration signal |

| Skewness | A measure of the asymmetry of the vibration signal distribution |

| Expectation | Average value of the vibration signal |

2.3 Variational Mode Decomposition (VMD)

VMD is a powerful signal – processing technique. First, the modal function is transformed into an amplitude – modulated and frequency – modulated signal. Then, by introducing a quadratic penalty factor and a Lagrange multiplier, the target function is defined to ensure signal reconstruction accuracy. Through iterative updates, the optimal solution of the modal components and the corresponding center frequencies are obtained. Table 4 shows the main steps of VMD in a more accessible way.

| Step | Description |

|---|---|

| Transformation | Convert the modal function to an AM – FM signal |

| Defining the target function | Incorporate penalty factor and Lagrange multiplier to form the target function |

| Iterative updates | Update modal components, center frequencies, and Lagrange multiplier iteratively |

| Convergence check | Stop the iteration when a certain accuracy criterion is met |

2.4 Attention Network

Due to the strong time – series nature of the sensor – collected data, the same – parameter attention – concentration network is applied to three different types of data (fault data, equipment sick – operation data, and equipment healthy – operation data) in parallel. As shown in Figure 2, the network first adds position information to the data, then uses the self – attention mechanism for feature extraction. Batch Normalization is applied to speed up the calculation and prevent gradient disappearance. The processed data is further transformed by the feed – forward neural network to achieve multi – layer attention – concentration network.

[Insert Figure 2: Self – Attention Network Structure Diagram]

2.5 Data Enhancement and Loss Setting

In industrial data collection, the number of samples in the sick – operation and normal – operation states is often small. To address this issue, data enhancement is carried out. Random samples from different operation states are selected and combined to form new feature vectors. The distance between positive and negative samples is calculated using the Euclidean norm. The loss function of the entire network is defined to optimize the network structure through backpropagation. Table 5 shows the data enhancement and loss – setting process in detail.

| Process | Details |

|---|---|

| Data enhancement | Randomly select samples from different states to form new feature vectors |

| Distance calculation | Calculate the distance between positive and negative samples using the Euclidean norm |

| Loss function definition | Define the loss function as a function of positive and negative sample distances and a hyperparameter |

3. Experimental Analysis

3.1 Experimental Data

To monitor the running state of the mixer’s gear reducer in real – time, acceleration sensors are deployed in the X – direction, Y – direction, and radial direction of the equipment’s bearing. Vibration intensity data is collected at a frequency of 20kHz. Table 6 shows the data monitoring range, including the equipment name, measurement point location, number of measurement points, analysis frequency, collection density, and sensor type. Table 7 presents some of the original data in the form of one – dimensional digital signals.

| Equipment Name | Measurement Point Location | Number of Measurement Points | Analysis Frequency | Collection Density | Sensor Type |

|---|---|---|---|---|---|

| Gear Reducer | Multiple locations (e.g., motor free end, motor drive end) | 6 | 2kHz | 2h | RH505, RH625 |

| Original Data | Values |

|---|---|

| x | A series of one – dimensional digital values representing vibration signals |

3.2 Experimental Environment

The experiment is conducted in a specific environment. The operating system used is Windows 11, with a GeForce RTX 3080 GPU, an Intel Core i7 – 8750h CPU, 16GB of RAM, Python 3.7 as the programming language, and PyTorch 1.10.0 as the deep – learning framework. Table 8 summarizes the experimental environment parameters.

| Name | Parameter |

|---|---|

| Operating System | Windows 11 |

| GPU | GeForce RTX 3080 |

| CPU | Intel Core i7 – 8750h |

| Memory | 16GB RAM |

| Python | 3.7 |

| PyTorch | 1.10.0 |

3.3 Experimental Results and Fault Diagnosis

The data is divided into three categories: fault data (collected 1 month before the fault occurs), sick – operation data (collected 4 – 1 months before the fault occurs), and normal – operation data. The feature values of the three types of data are calculated according to the formulas in Section 2.2, as shown in Table 9.

| Fault Type | Margin | Peak – to – Peak Value | Waveform Index | Pulse Index | Skewness | Expectation |

|---|---|---|---|---|---|---|

| Normal Operation State | [Value] | [Value] | [Value] | [Value] | [Value] | [Value] |

| Sick – Operation State | [Value] | [Value] | [Value] | [Value] | [Value] | [Value] |

| Fault State | [Value] | [Value] | [Value] | [Value] | [Value] | [Value] |

The collected vibration signals are subjected to VMD decomposition and then input into the model for training and prediction. In the VMD decomposition stage, specific parameters are set, such as a bandwidth limit empirical value of 20000, a decomposition modal number of 8, and a control error size constant of 0.001. Figures 3 – 5 show the amplitude – frequency diagrams of the normal – operation state, sick – operation state, and fault state after VMD decomposition, respectively. Figures 6 – 8 display the center – frequency distributions of the three types of data. It can be observed that there are significant differences in the frequency distributions and iteration times between normal – operation data and fault data.

[Insert Figure 3: Normal – Operation State Amplitude – Frequency Diagram]

[Insert Figure 4: Sick – Operation State Amplitude – Frequency Diagram]

[Insert Figure 5: Fault State Amplitude – Frequency Diagram]

[Insert Figure 6: Normal State Center – Frequency Distribution]

[Insert Figure 7: Sick – Operation State Center – Frequency Distribution]

[Insert Figure 8: Fault State Center – Frequency Distribution]

3.4 Result Analysis

The experimental results show that there are obvious differences in the signal distributions of normal – operation data and fault data in the six features mentioned above. After VMD decomposition, the frequency distributions of fault data and normal – operation data are significantly different, especially in the 1 – times and 8 – times frequencies. In model training, fault data and sick – operation data require more training time to reach the same amplitude as normal – operation data, especially at 8 – times frequency. The proposed model achieves an accuracy rate of 83.33% in fault prediction, as shown in Figure 9.

[Insert Figure 9: Model Prediction Accuracy]

4. Conclusion

This article presents a fault – mixing prediction analysis model based on standard gear reducers. By comprehensively using techniques such as vibration signal feature extraction, variational mode decomposition, and self – attention network feature extraction, the model can effectively predict equipment failures. However, there is still an issue of data sparsity. If the data distribution of different types is more uniform, the prediction accuracy of the model is expected to be further improved. Future research can focus on data – augmentation techniques to address the data – sparsity problem and explore more advanced neural – network architectures to enhance the model’s performance.