1.Strength analysis of planet carrier

In the planetary reducer, the planet carrier is often the part with the largest torque, and its modeling structure features are many, which is not conducive to theoretical calculation, so we carry out finite element analysis on the planet carrier.

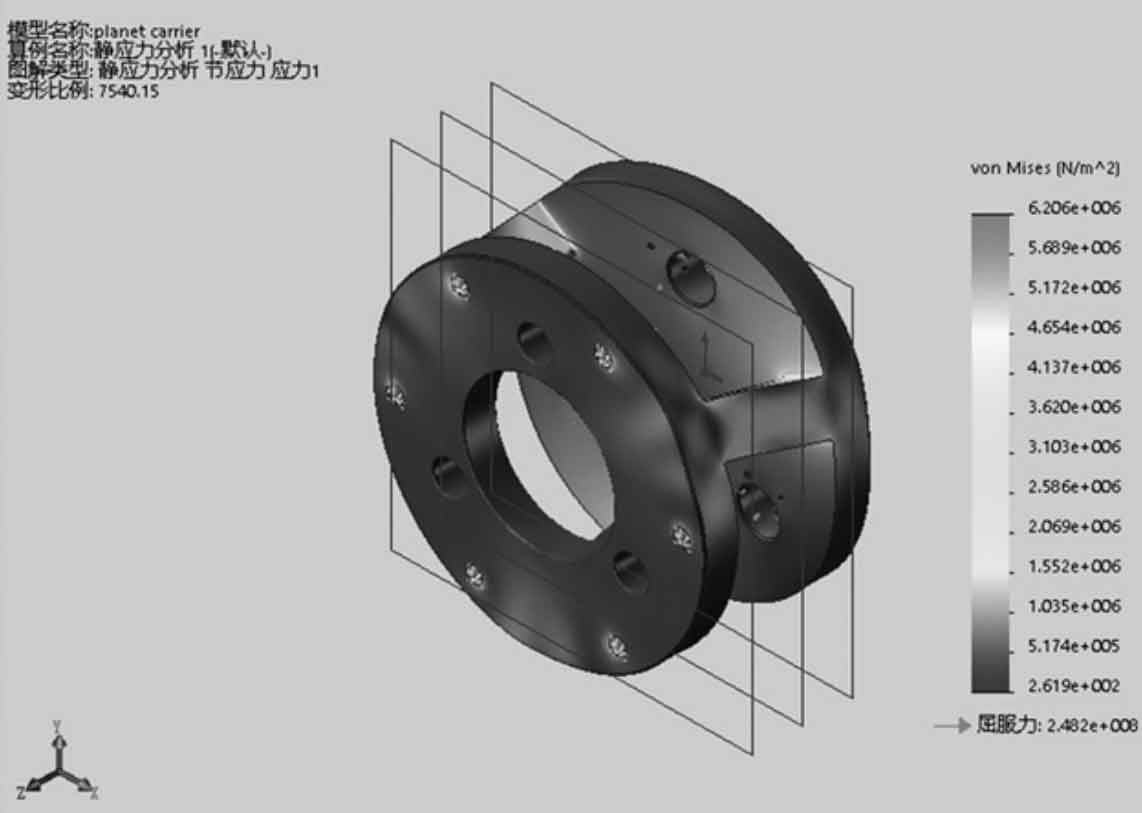

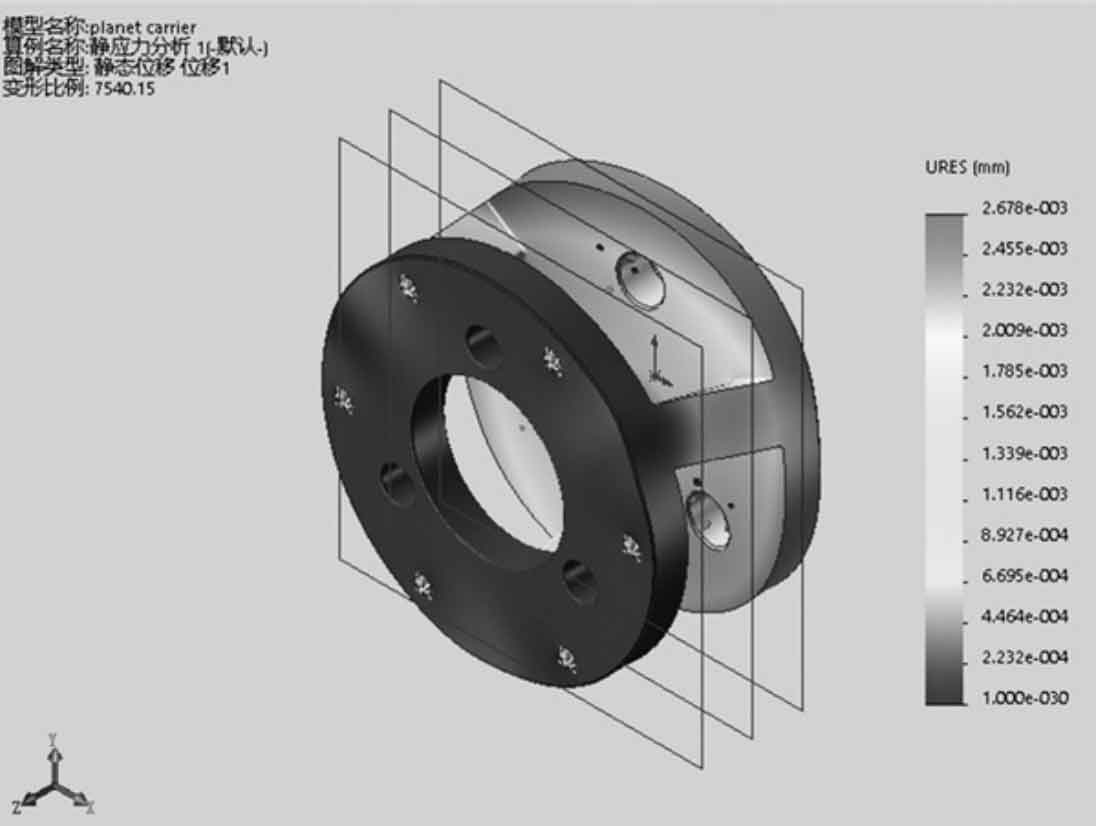

According to the above design, one end of the planet carrier is fixedly connected with the reducer housing and remains stationary, while the other end receives the torque of the planet gear. The torque of each planetary gear is 17.56 N/mm2, and three torques act on the planetary carrier in one direction. According to the actual stress of the planetary gear, load it onto the 3D model for analysis. Figure 1 shows the stress analysis diagram of the planet carrier, and Figure 2 shows the displacement analysis diagram of the planet carrier.

According to Figure 1, the maximum stress of the planet carrier is 6.2 MPa, and the yield strength of the selected material ZG310-570 is 310 MPa, which is far lower than the yield strength of the material. Therefore, the planet carrier conforms to the design.

2.Strength analysis of ring gear carrier

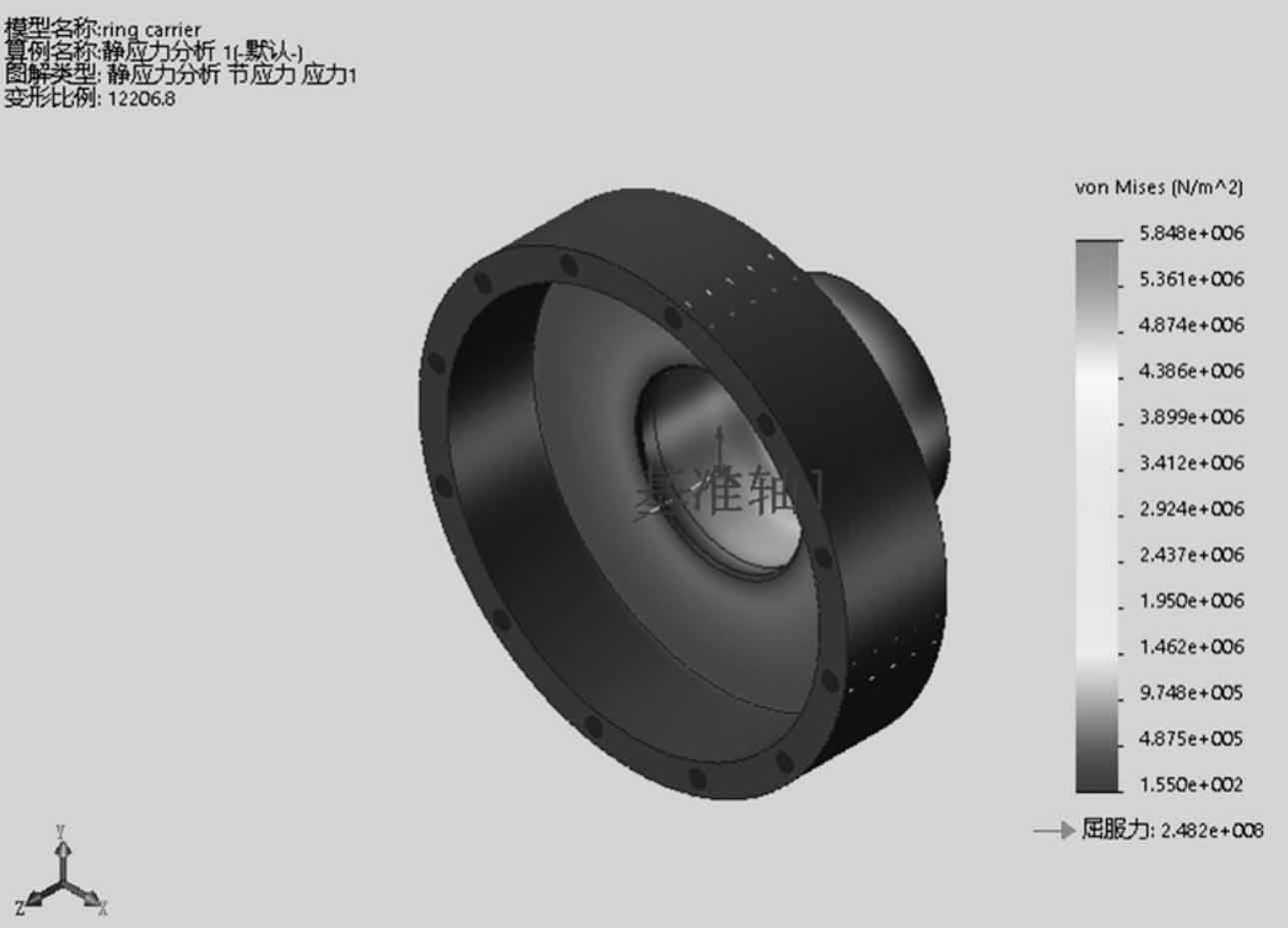

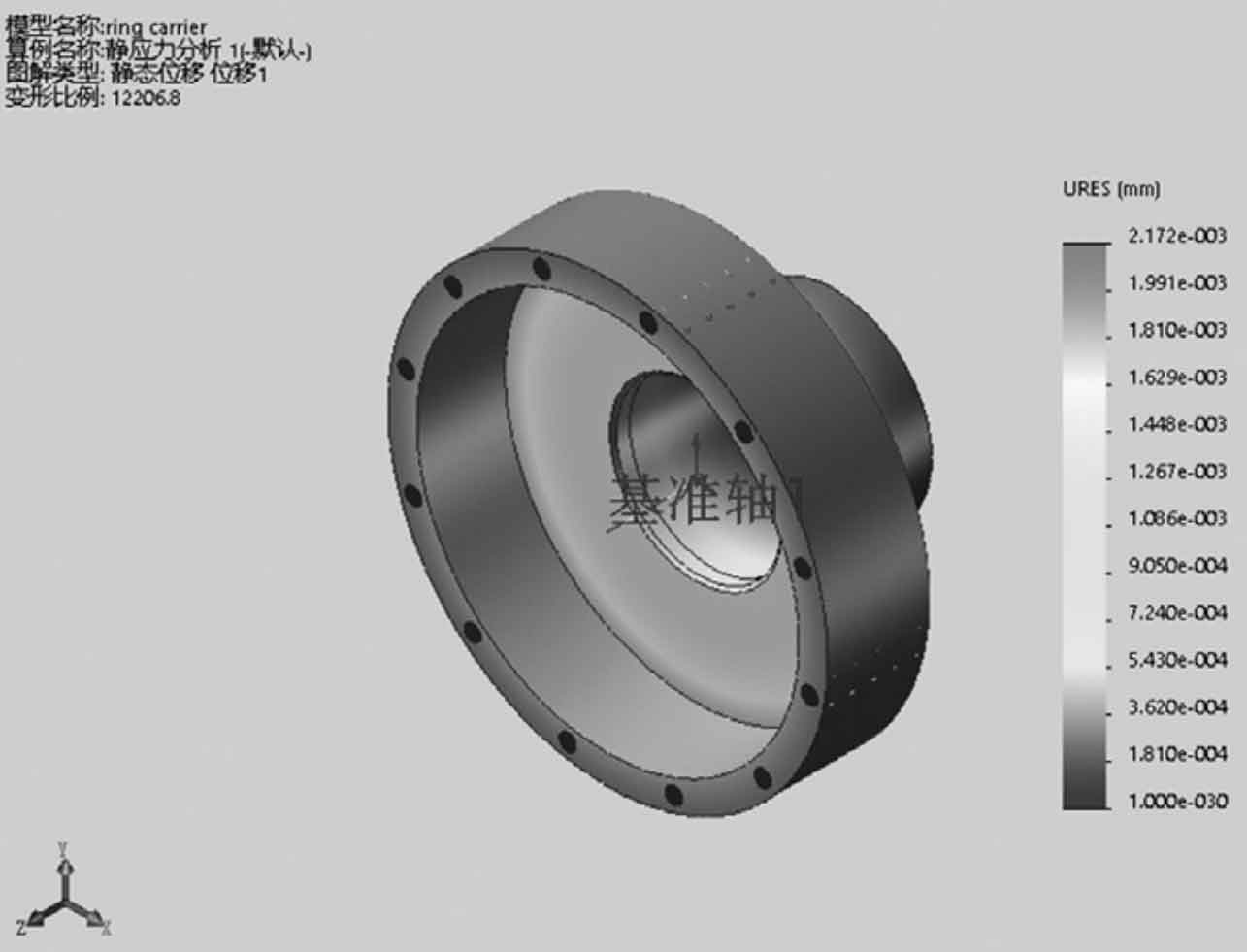

The gear ring carrier is the torque output structure in this design, so the finite element analysis is carried out for this part. The results of stress and displacement analysis are shown in Fig. 3 and Fig. 4.

One end of the gear ring carrier is connected with the inner gear ring, and the other end is connected with the brake disc and the hub to transmit the torque of the inner gear ring to the hub. Therefore, the end connected with the hub is set to be stationary, and the end connected with the gear ring is loaded with torque, the torque is 113.09 N/mm2, which acts on the surface connected with the gear ring.

It can be seen from Figure 3 that the maximum stress on the ring gear carrier is 5.84 MPa, which is far lower than the material yield strength of 310 MPa, so the design of the ring gear carrier meets the strength requirements.