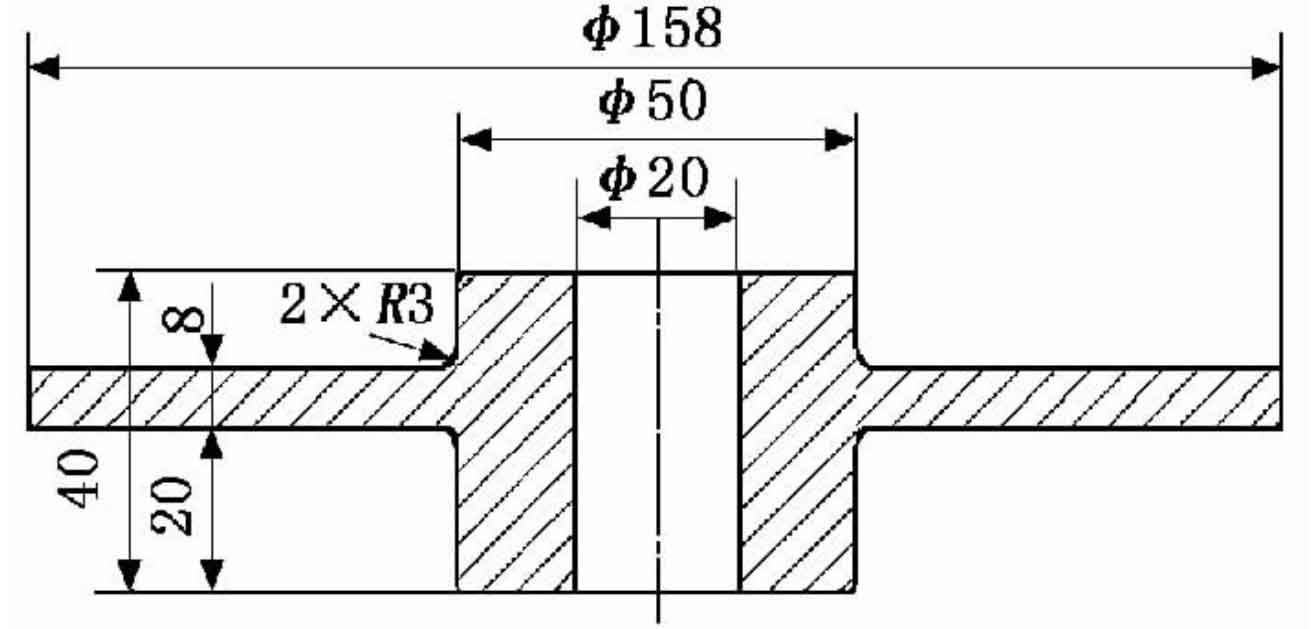

A gear blank requiring precision forging is studied. The number of teeth of the gear is 29 and the diameter of the addendum circle is Φ 155mm, tooth thickness 8mm, hub height 40mm, hub diameter Φ 50mm, inner hole diameter Φ 20mm, with 5mm punched skin. Because a certain machining allowance should be reserved, the diameter of the outer circle of the gear blank is taken as Φ 158mm。 The structural diagram of gear blank is shown in Figure 1, and the structural diagram of gear blank precision forging die is shown in Figure 2.

After calculation, the volume of the gear blank V ≈ 208689.717m3. In addition to the volume of the forging itself, a small amount of machining allowance and flash should be added to the volume of the gear blank, so its volume is 214413.699mm3.

Because the gear blank is a rotating body, the cylindrical bar is selected for precision forging. The forming process of the gear blank is simulated by taking cylindrical bars with different diameters. Based on DEFORM-3D finite element analysis software, the flow law of metal and the distribution of equivalent effect variable field in gear under different height diameter ratio are analyzed.

According to the principle of constant volume, the number of finite element mesh elements of each scheme is 50000, and the simulation step length is 1 / 3 of the minimum element length.