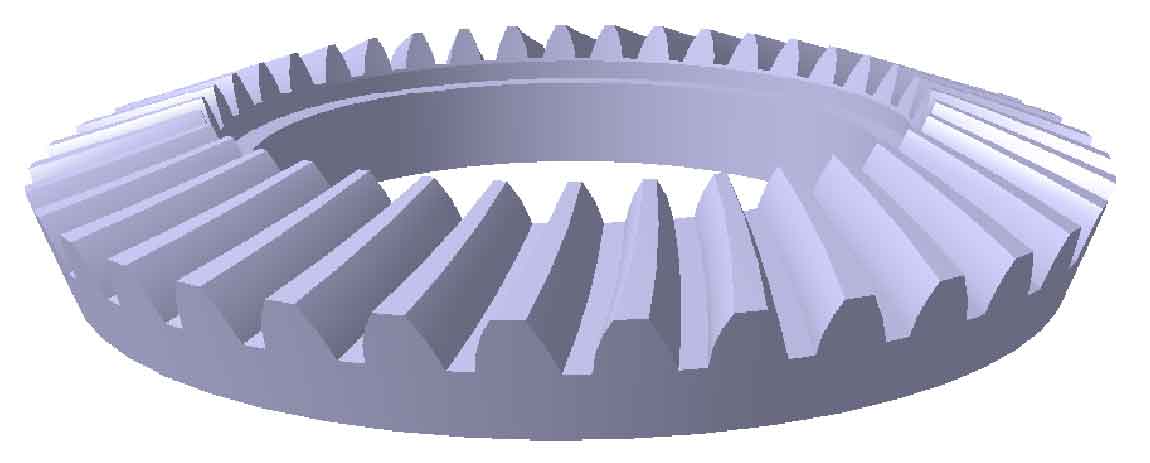

The three-dimensional mathematical model of the driven spiral bevel gear of the automobile rear axle is established by CATIA V5R21. The analysis of spiral bevel gear can generally be simplified to the analysis of equivalent cylindrical gear, but the accuracy of three-dimensional modeling of spiral bevel gear based on equivalent cylindrical gear is not enough. Based on the mathematical model of spherical involute, the tooth profile model and tooth profile mathematical model of spiral bevel gear will be established, and the parametric modeling of spiral bevel gear will be carried out.

In this paper, CATIA V5R21 is used to carry out parametric modeling for the driven spiral bevel gear of automobile rear axle. The specific steps are as follows:

(1) Calculate the geometric parameters of spiral bevel gear required for modeling, especially the geometric parameters of tooth profile;

(2) Draw the large end tooth profile, small end tooth profile, tooth top tooth profile and tooth root tooth profile of the spiral bevel gear;

(3) Through the multi section sweeping function, the large and small end tooth profiles are swept along the helix to form a single tooth surface model;

(4) The single tooth curved surface model is closed to form a single tooth solid;

(5) Spiral bevel gears are formed through an array.

After the three-dimensional mathematical model of spiral bevel gear is obtained, the pre forging and final forging of gear precision forging can be designed according to the process needs, and the three-dimensional mathematical model of pre forging and final forging can be obtained by modifying the three-dimensional mathematical model of spiral bevel gear. Then, the three-dimensional mathematical model of die can be easily obtained by using the removal function of Boolean operation in CATIA v5r21. Figure 1 and Figure 2 are the two-dimensional and three-dimensional mathematical models of the pre forging and final forging of the driven spiral bevel gear of the automobile rear axle studied in this paper.