In the precision forming process of spiral bevel gear, the fluidity of metal materials is poor, the tooth shape is not easy to fill, and the stress condition of its die is very complex. Therefore, the mold structure to be designed should pay attention to the following points:

One is to have a strong mold filling ability, which can ensure that the metal material completely fills the mold cavity;

Second, the designed die should have sufficient strength and stiffness and good wear resistance;

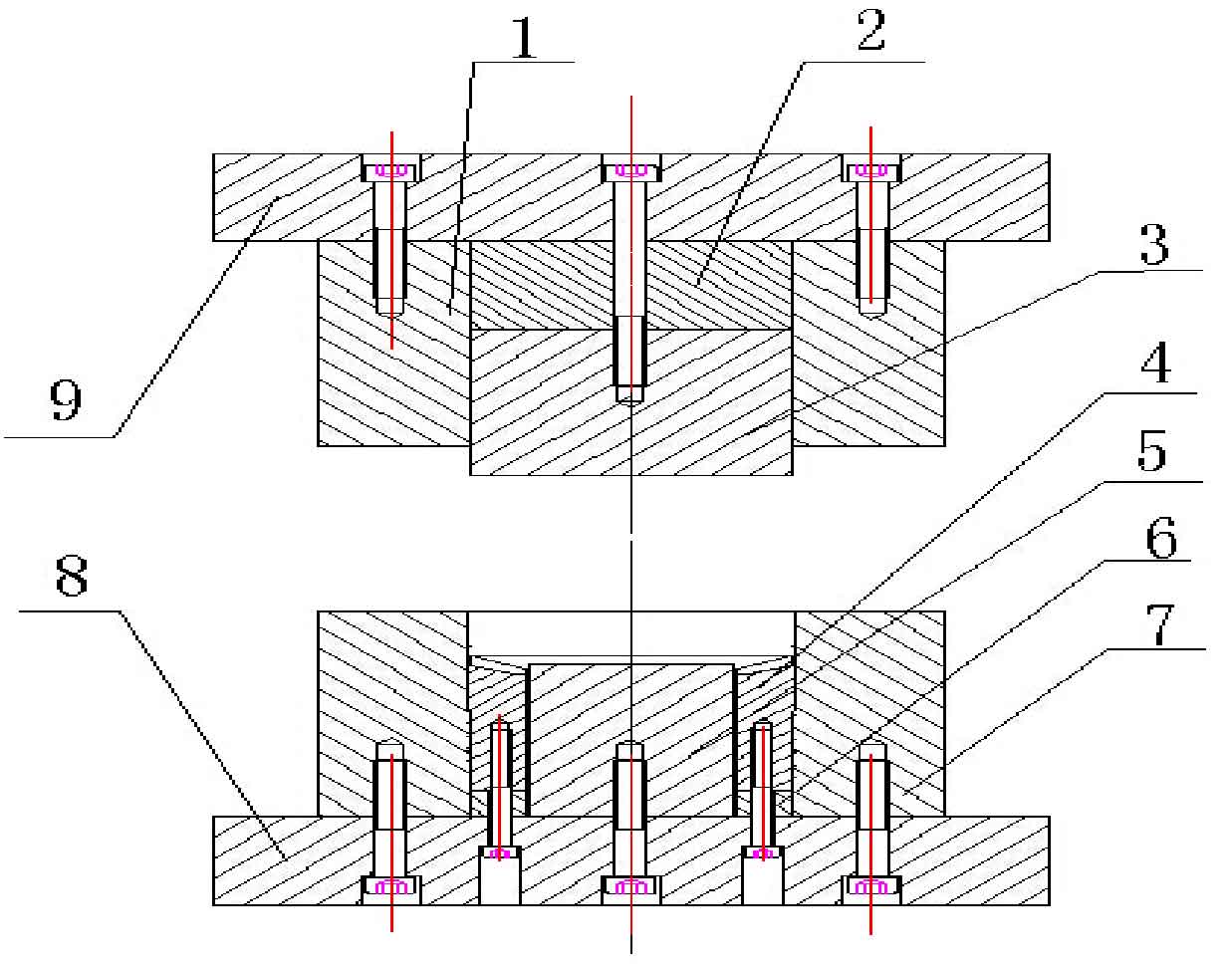

Third, the test shall be convenient for disassembly and replacement of parts. Combined with the selected test equipment and the designed test scheme, the test mold structure is designed as shown in the figure.

By adjusting the height of the upper backing plate 2 and the upper ejector rod 3 and cooperating with the lower ejector rod 5 and the gasket 6, the influence law of various process parameters on the tooth shape forming characteristics of spiral bevel gear is studied to verify the accuracy of the numerical simulation results.