In order to achieve the effect of simulation, the initial stress of spur bevel gear blank material needs to be applied to the finite element model of spur bevel gear blank. At present, there are two methods of applying initial stress:

The first method is to discretize the initial residual stress distribution curve into several points, and then apply the stress value corresponding to each point to the element of the corresponding layer of spur bevel gear blank;

The second is to fit the stress curve into an equation and compile the program code according to the expression of the equation, so that the initial stress is applied to each unit of the split spur bevel gear blank.

Among them, when the first method discretizes the points on the curve, the more discrete points, the smaller the error, but at the same time, the amount of calculation will be larger and the operation will be more complex; Although the second method needs curve fitting, as long as the appropriate fitting method is adopted, the error caused by fitting can be ignored, and the continuous application of stress can be guaranteed to improve the calculation accuracy of finite element analysis. Combining the advantages and limitations of the two methods, the second method is selected.

According to the characteristics of the initial stress distribution law expressed in Figure 1, input the data of each discrete point in the broken line diagram into Matlab software, and prepare the corresponding program for Fourier curve fitting. The relationship between the initial residual stress in two directions and the thickness of spur bevel gear blank is expressed by function. The fitting formula is as follows:

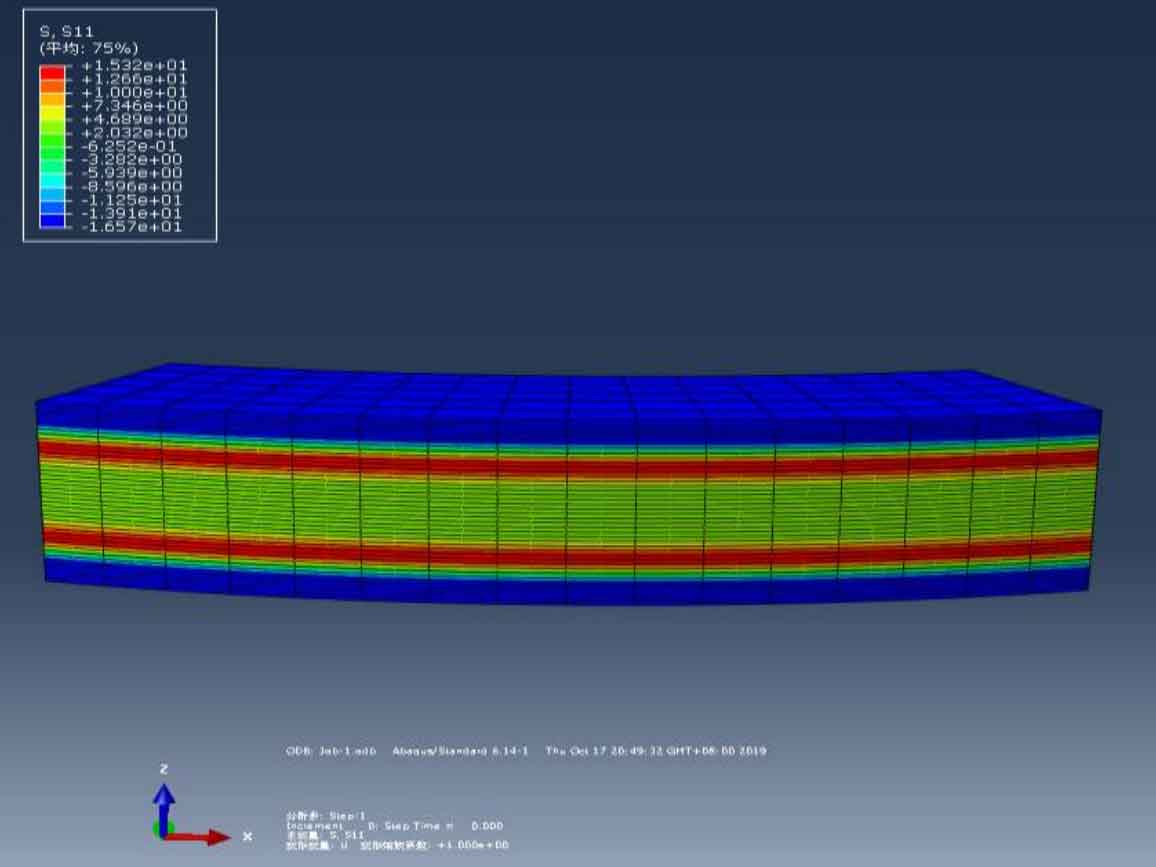

The function expression obtained by fitting is compiled in Visual Studio software with FORTRAN language. Sigma (1) and sigma (2) in the subroutine represent the stress in X direction and Y direction respectively. By default, the tensile stress of spur bevel gear blank is expressed with positive value and the compressive stress is expressed with negative value. Then edit the keyword of the finite element model InP file in the finite element software, and add “* initial condition, type = stress” before the initial analysis step of the model input file, so that the finite element model can introduce the initial stress condition in the subroutine during analysis and operation. After the attribute conditions of the finite element model are set, the operation file is created in the “operation” module of the finite element software, and then the sigini subroutine prepared in advance is added to the operation file, and then the modified InP file is submitted for analysis and calculation. The finite element software will call the sigini subroutine in the calculation process to realize the automatic and continuous application of the initial residual stress of the straight bevel gear split wheel blank, The straight bevel gear blank after applying the initial internal stress is shown in Figure 2.