1. Import model

Through the method discussed above, we can establish the three-dimensional model of the modified cylindrical gear in Pro / E, then import the geometric model into ANSYS Workbench, give the material attribute of the model as “structural steel” in the mechanical module, and modify the material attributes such as density, elastic modulus, Poisson’s ratio and other materials according to the analysis. For the contact of meshing tooth surface, the imported model defaults to “binding” contact, which is inconsistent with the actual situation. It is modified to “friction” contact, and the friction coefficient is set to 0.2.

2. Meshing

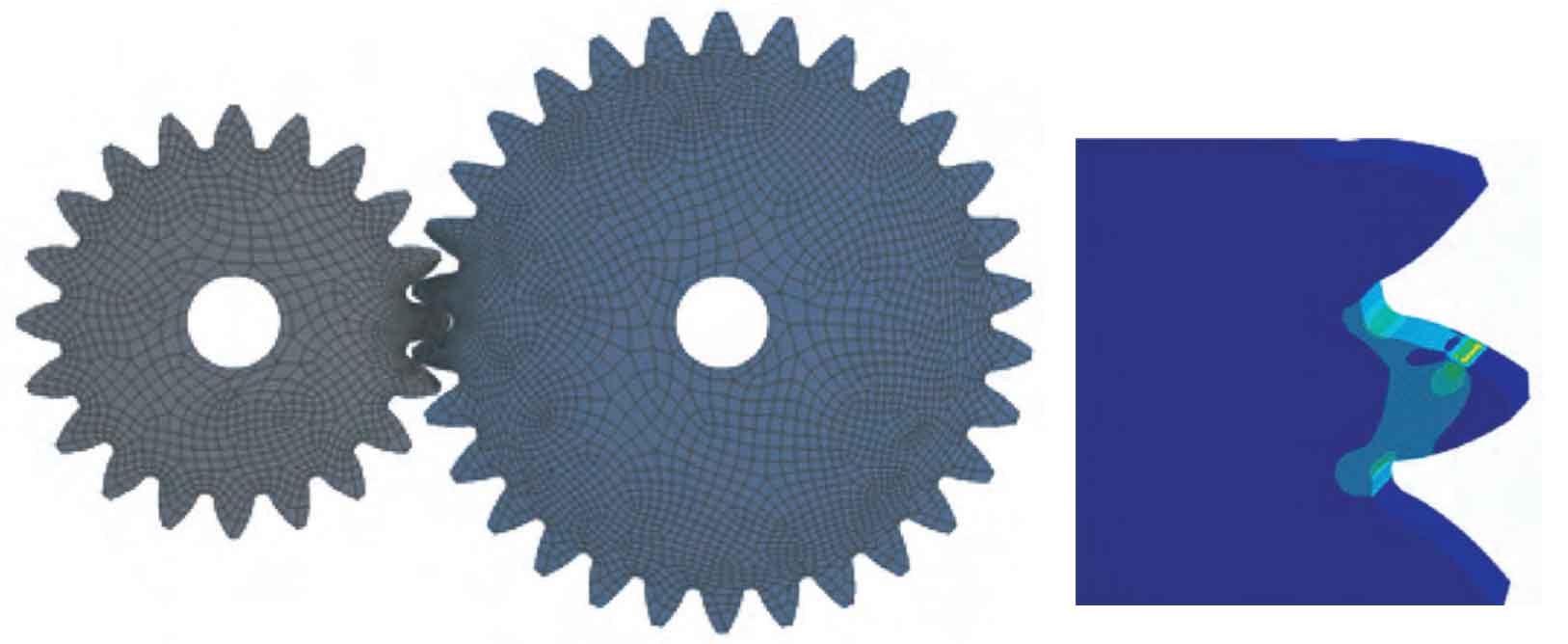

Because we mainly focus on the tooth surface contact stress and tooth root bending stress of cylindrical gear meshing teeth, it is necessary to refine the mesh of the tooth surface and tooth root of cylindrical gear meshing, and the default mesh size can be used for non meshing teeth. This is also helpful to the calculation of contact. For example, if the mesh is too thick, the initial gap of contact may be too large and the solution error may be caused.

3. Load and constraint

For cylindrical gear transmission, we apply torque load. Create a new “cylindrical coordinate system” on the cylindrical surface where the pinion shaft hole is located, in which the cylindrical gear rotation axis is the z-axis, the tooth width center plane is the z = 0 plane, and the Y direction is the degree of freedom of rotation along the axis. Apply displacement constraints x = 0 and z = 0 to the cylindrical surface of the pinion shaft hole in the above cylindrical coordinate system, retain the rotational freedom (y) along the Z axis, and apply torque load m to the cylindrical surface at the same time. The big gear exerts a “fixed” constraint on the cylindrical surface where the shaft hole is located. After the constraint and load are loaded, solve the model and check the stress nephogram of the meshing teeth, as shown in the figure, the tooth surface contact and tooth root bending stress can be obtained.