According to the working characteristics of gears, during the transmission of power and motion, the gear will generate bending stress at the root of the teeth, contact stress at the tooth surface and friction force when the gears move together.Bending stress will cause deformation and fracture of the teeth, contact stress will cause fatigue flaking of the teeth surface, and friction will cause wear of the teeth.The fatigue failure of large helical gears under bending stress can be judged by the form and location of failure.When the bending stress is greater than the bending fatigue limit of the gear, the fatigue crack will germinate and propagate near the root of the gear and eventually lead to the failure of the gear teeth.

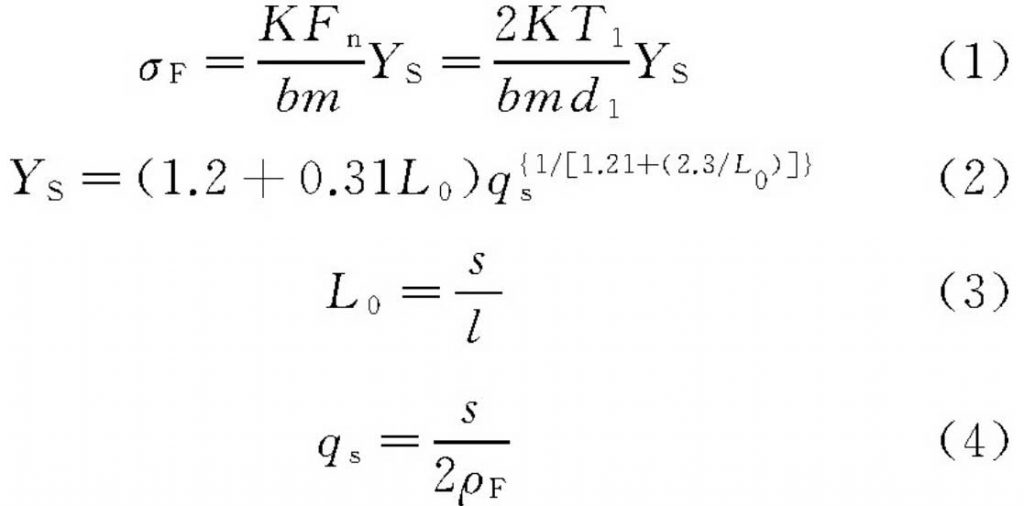

In calculating the bending stress of gears, because of the high rigidity of gears, the teeth are generally considered as cantilever beams with width b, and the forces during operation are shown in Figure 1.Tooth is subject to alternating bending stress during operation, and fatigue cracks are formed near the root of the tooth. With the continuous movement, fatigue cracks will gradually expand and lead to tooth fracture failure.The stresses generated during the running of the teeth can be expressed as follows:

Medium: F is the root bending stress; Fn is the working circumferential force; B is the tooth width; m is the modulus; K is the load factor; T1 is the rated torque; D1 is the pinion diameter; YS is the root stress concentration factor; L0 is the tooth parameter; QS is the root fillet parameter; s is the root fillet parameter; s is the tooth thickness; L is the tooth height; and Rho F is the root fillet curvature radius.

It can be seen from equation (1) ~ (4) that the bending stress F of the root is mainly determined by the radius of curvature of the radius of radius of radius of radius of radius of radius of radius of radius of curvature of radius of radius of radius of radius of radius of radius of radius of radius