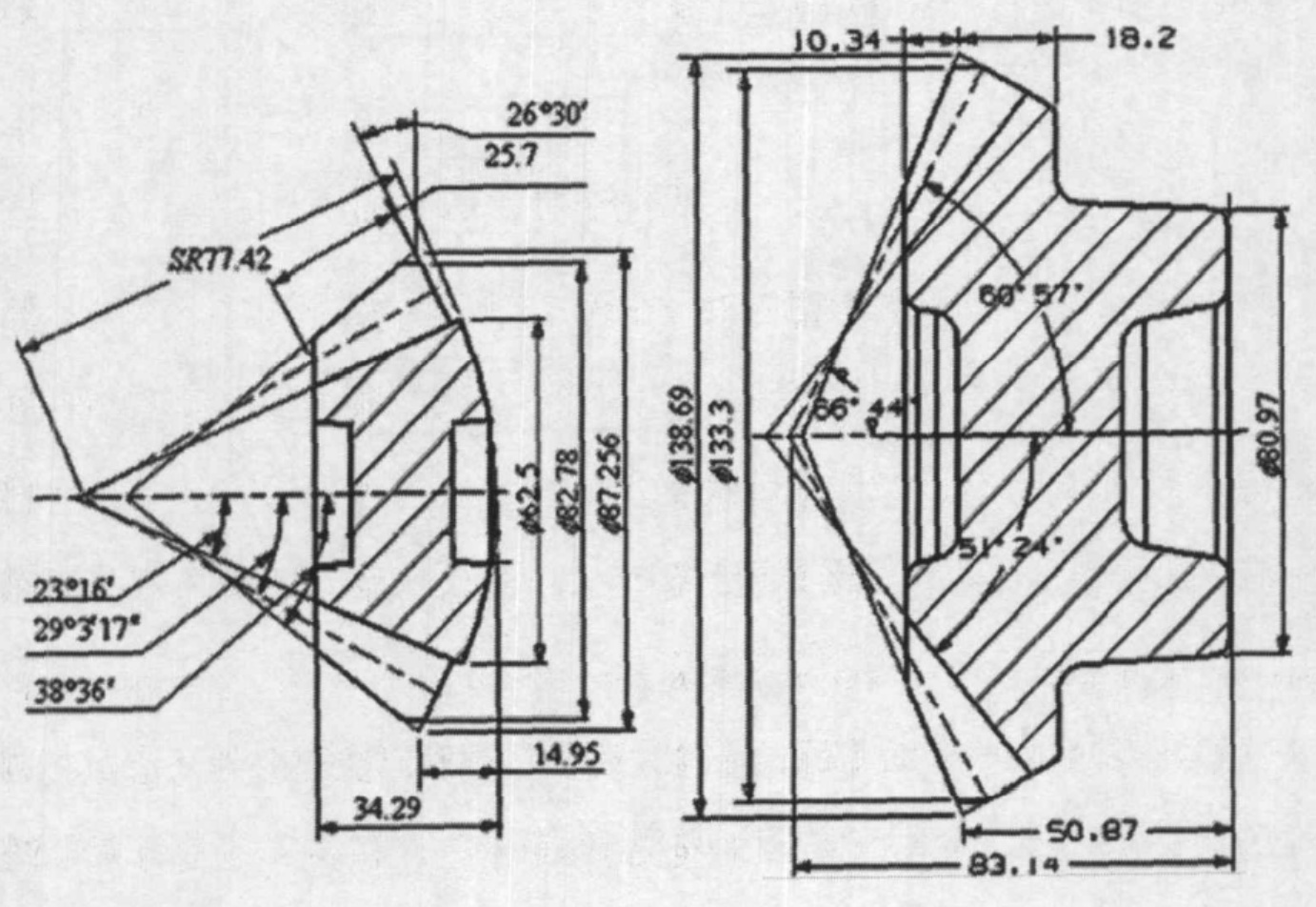

Fig. 1 shows the forging drawing of planetary gear and half shaft gear. When formulating the forging drawing of bevel gear, the following aspects should be considered:

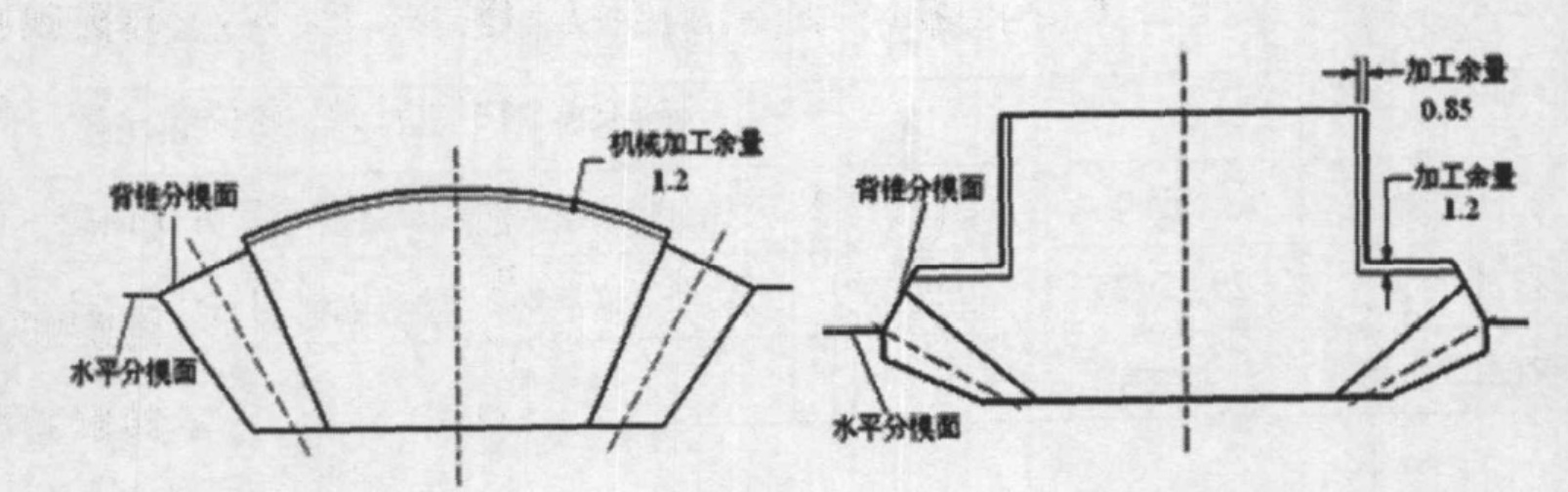

(1) When determining the parting surface of open die forging bevel gear, the parting surface is composed of back cone parting surface and horizontal parting surface. Considering that the tooth cavity can be fully filled and the forging can be smoothly molded, the horizontal parting surface of the planetary gear is set at the tooth tip of the big end of the gear, and the horizontal parting surface of the halfshaft gear is moved from the tooth tip of the big end to the junction of the inverted crown and the back cone, as shown in Figure 2.

(2) Determine machining allowance: 1.2mm machining allowance shall be reserved on the installation spherical surface of the back cone of the planetary gear, and 1.2mm and 0.85mm unilateral machining allowance shall be reserved on the installation datum plane of the big end and the cylindrical surface of the half shaft of the half shaft gear, as shown in Figure 2.

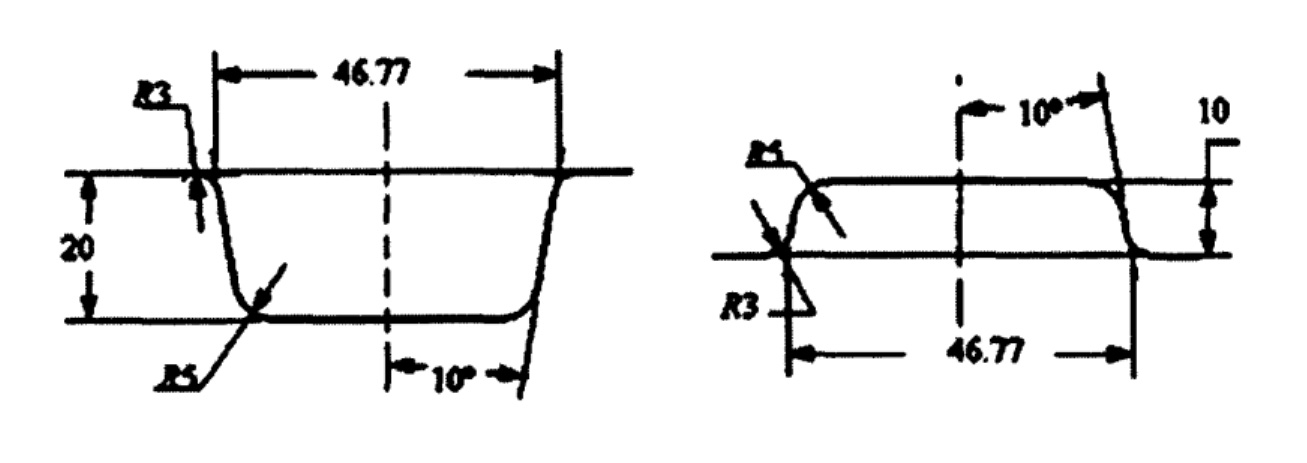

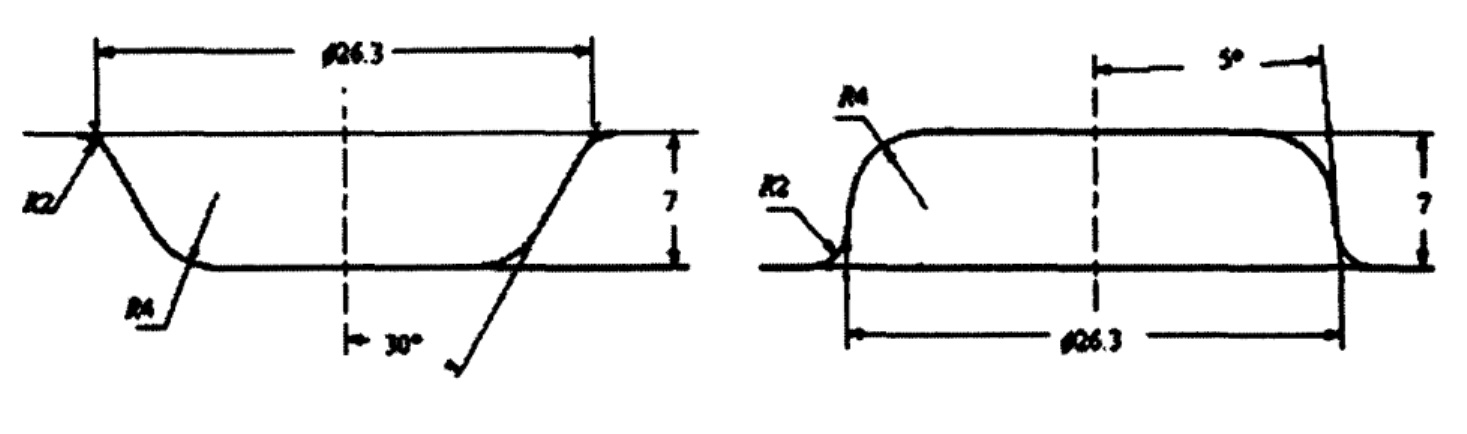

(3) The double blind hole structure is adopted, and the double blind hole dimension parameters of planetary gear and half shaft gear forgings are given in Figure 3 and 4 respectively.