Folding is a common defect in gear forging production, which is formed by the local convergence of oxidized metal surfaces at high temperature and pressed into the forging. On the machined surface, it is generally difficult to distinguish between gear forging folding and cracks in appearance, but the tail of gear forging folding is generally round and blunt, and the metals on both sides of the gear forging folding area usually have oxidation and obvious decarburization. The gear forging folding destroys the integrity of the forging surface, and the residual stress concentration point is formed on the part surface, which is easy to lead to the fracture failure of the part in use.

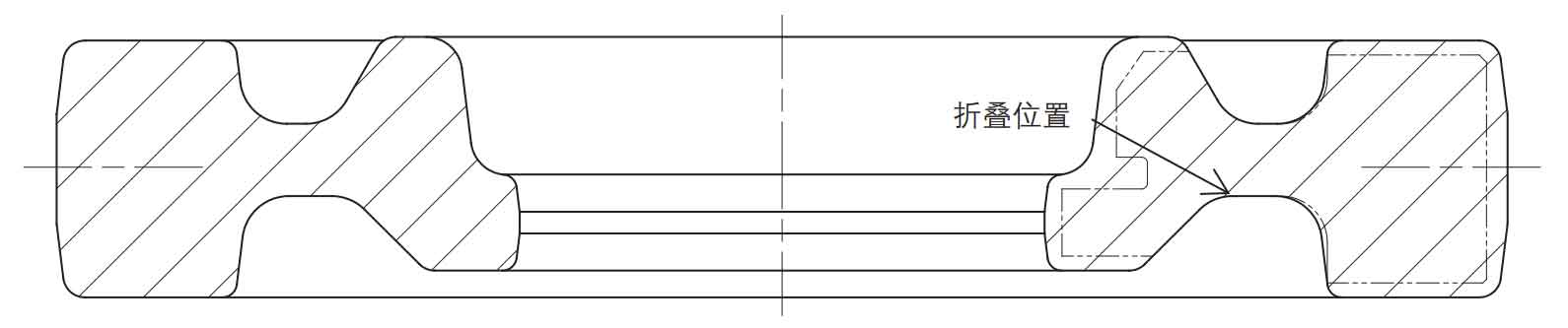

A gear processing workshop of ZHY gear processed a batch of transmission second shaft and second gear parts (hereinafter referred to as “second shaft gears”) made of 20CrMnTi. When installing the positioning end face after carburizing and quenching, it was found that some parts had defects of suspected gear forging and folding distributed along the circumferential direction near the inner hole. The location and appearance of the defects are shown in Fig. 1, Fig. 2 and Fig. 3.

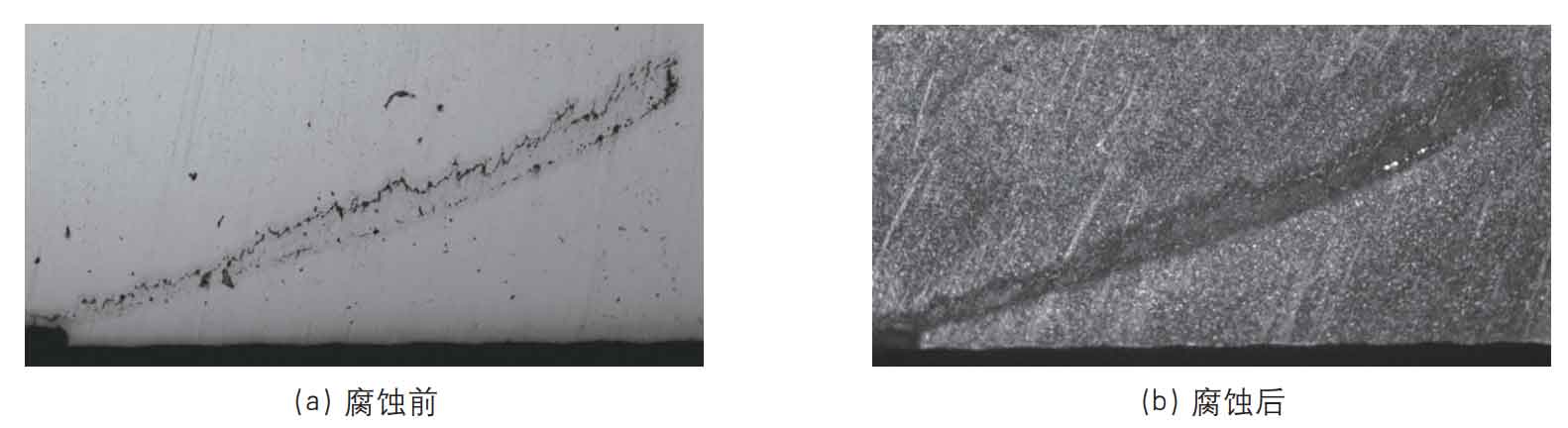

Cut the fracture along the radial direction and under the metallographic microscope (100 ×) Through observation, it is found that there are inclusions in the defect area and the end is round and blunt, which does not meet the characteristics of quenching cracks. After corrosion with nitric acid alcohol solution, it is impossible to judge whether the metals on both sides have decarburized after carburizing and quenching process (Fig. 4) However, it can be judged that it is a typical gear forging folding defect. About 6% of the parts with gear forging folding defects can only be scrapped because they cannot be repaired, and the scrap rate is very high.

Through the analysis of the forging folding of the end face gear after the hot machining of the second shaft and second gear of a certain type of transmission, it is concluded that the reason for the forging folding of the gear is that the metal flowing out of the skin during the final forging is not smooth, which drives the surface metal to be drawn into the forging, forming the forging folding of the gear. For this reason, the die size is adjusted, and the deform simulation results show that the forging folding of the gear is not smooth The proposed cause analysis and solution for gear forging folding provide a reference for similar parts to solve similar gear forging folding, and also provide an idea for the new design of similar parts to prevent gear forging folding.