1.Microstructure and performance requirements of forged gear blank

20CrMnTi is selected as the material of automobile gearbox gear. The technical requirements for isothermal normalizing of gear blanks are as follows:

1) The grain size is grade 5 ~ 8;

2) According to GB / t13299-1991 “evaluation method of microstructure of steel”, the banded structure is ≤ grade 2, there is no bainite structure, and the widmanstatten structure is ≤ grade 1;

3) According to GB / t13320-1991 “metallographic structure evaluation diagram and evaluation method of steel die forgings”, the qualification level is level 1 ~ 4;

4) Hardness: 160 ~ 190hbw.

2.Microstructure and properties after common normalizing

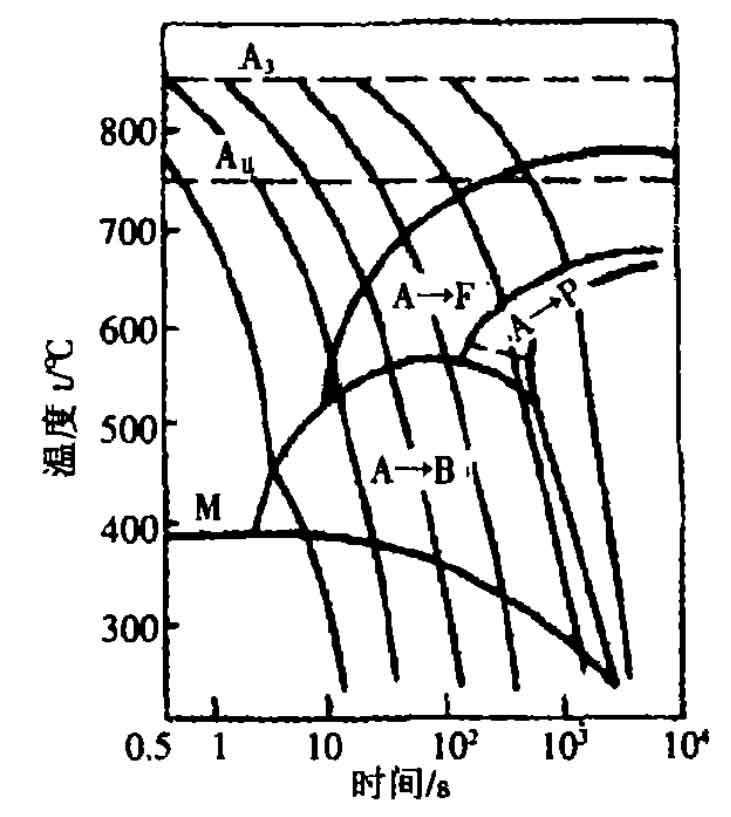

The steel material is heated and forged at 1200 ~ 1250 ℃, and the forging is stopped at 1050 ~ 1000 ℃ and air cooled to room temperature. At this time, the microstructure is pre eutectoid ferrite and widmanstatten ferrite, pearlite and bainite with uneven composition, coarse grain (grade 2 ~ 3) and high hardness (220 ~ 280hbw). The forging blank cooled to room temperature is heated at (930 ± 10) ℃ for 1H and then air cooled. Its hardness is 168 ~ 230hbw, the hardness dispersion is 30 ~ 62hbw, the metallographic structure is granular bainite, ferrite and pearlite (b particle + F + P), and the grain size is grade 3 ~ 4. Obviously, it is difficult to meet the microstructure and performance requirements of forged gear blanks. From the continuous cooling transformation (CCT) curve of 20CrMnTi steel in Figure 1, it can be seen that different cooling rates obtain different microstructure and hardness, and it can also be seen that bainite structure will appear in a large cooling rate range. The formation temperature of this bainite is slightly higher than that of upper bainite, which is bainite distributed in bulk ferrite. Because bainite is granular, it is called “granular bainite”. This structure is hard and tough, which worsens the machinability of steel. The microstructure transformation of ordinary normalizing is completed under continuous cooling conditions, and the cooling conditions of different parts and different parts of the same part (such as surface and core) are different, so the uniformity of microstructure transformation, hardness and stress distribution is poor. The hardness difference of the same gear blank is 30 ~ 62hbw. Therefore, it is very difficult to control the dimensional accuracy of parts in the process of cutting (especially in the process of high-speed cutting). Especially, it is difficult to control the tooth profile, tooth direction and cumulative error in the process of high-speed shaving and spline rubbing. Therefore, it is not appropriate to normalize 20CrMnTi steel gear blank as preliminary heat treatment.

3.Carburizing and quenching structure of air cooling parts after forging

The air-cooled steel parts after forging are made into smooth samples, which are carburized and quenched according to the process on the automatic carburizing line. The grain size of austenite was determined by hot corrosion method. The grains of different sizes were obtained, including 8 grades of fine and 3 grades of coarse. The results show that the coarse austenite grains with non-equilibrium structures such as bainite are hereditary, while the parts with equilibrium structures F and P do not have structural inheritance, and the grains are obviously refined. This shows that the heredity of coarse austenite grains after forging can be cut off by obtaining equilibrium structure before reheating austenite.

4.Microstructure and properties of isothermal normalizing with forging waste heat

The experimental results show that the initial forging temperature is 1200 ~ 1250 ℃, and most parts are at the upper limit of initial forging temperature; The final forging temperature is 1050 ~ 1000 ℃, most of which are in the middle limit. It takes about 3.5min for forgings to be air cooled from the final forging temperature to 800 ℃. The isothermal furnace is a 15kw box resistance furnace with a furnace temperature of 650 ℃. Considering the space spacing between workshops in actual production, the actual experimental temperature in the experimental site is 850 ℃, which is loaded into the isothermal furnace. Experimental data at different charging temperatures and different isothermal times.

By setting different charging temperatures, it is finally determined that the lower limit temperature of charging is to cool the workpiece to 800 ℃ after forging and enter the isothermal furnace. By setting different isothermal times, it is finally determined that 65 min is the lower limit of holding time in an isothermal furnace at 650 ℃. If the initial forging temperature is too high, the forging structure is obviously overheated, but there is no overburning. Since this isothermal normalizing can completely eliminate this structure and turn it into qualified structure, the grain is also improved

If it is refined, there is no need to reduce the initial forging temperature. There are two ways to produce non-equilibrium structure in alloyed carburized steel with coarse austenite grain during isothermal normalizing. One is that bainite or martensite appears when the actual temperature of billet after stopping forging is lower than BS point or MS; Second, the cooling rate is moderate after stopping forging, and strip ferrite w precipitates from austenite before isothermal α。 If pearlite transformation subsequently occurs; otherwise α- Fe widmanstatten structure. Although equiaxed ferrite and pearlite structure can be obtained by using low cooling rate, the hardness is too low to meet the technical requirements of normalizing. Therefore, the key is to increase the cooling rate and inhibit W α Precipitation. If a faster cooling rate is adopted after stopping forging and the minimum cooling temperature is controlled to be higher than the BS point, so that the billet does not undergo phase transformation before the isothermal temperature, and the isothermal transformation occurs before the F + P transformation at a lower temperature, it can not only avoid the formation of non-equilibrium structure, but also use the ratio of the large nucleation rate of phase transformation to the growth rate under large undercooling to form a moderate grain size F + P structure with qualified hardness.

5.Carburizing and quenching deformation of gears with different pre heat treatment

The gears after normal normalizing and isothermal normalizing were carburized and quenched respectively, and the deformation of the gears was measured. It can be seen that for gears with isothermal normalizing for pre heat treatment, due to uniform microstructure, carburizing and quenching deformation is less than that of ordinary normalizing, especially the deformation fluctuation range is small, which is very beneficial to control deformation. Therefore, for alloy carburized steel parts, only isothermal normalizing can reliably and stably obtain the microstructure and hardness required for heat treatment, and more effectively control the heat treatment deformation.