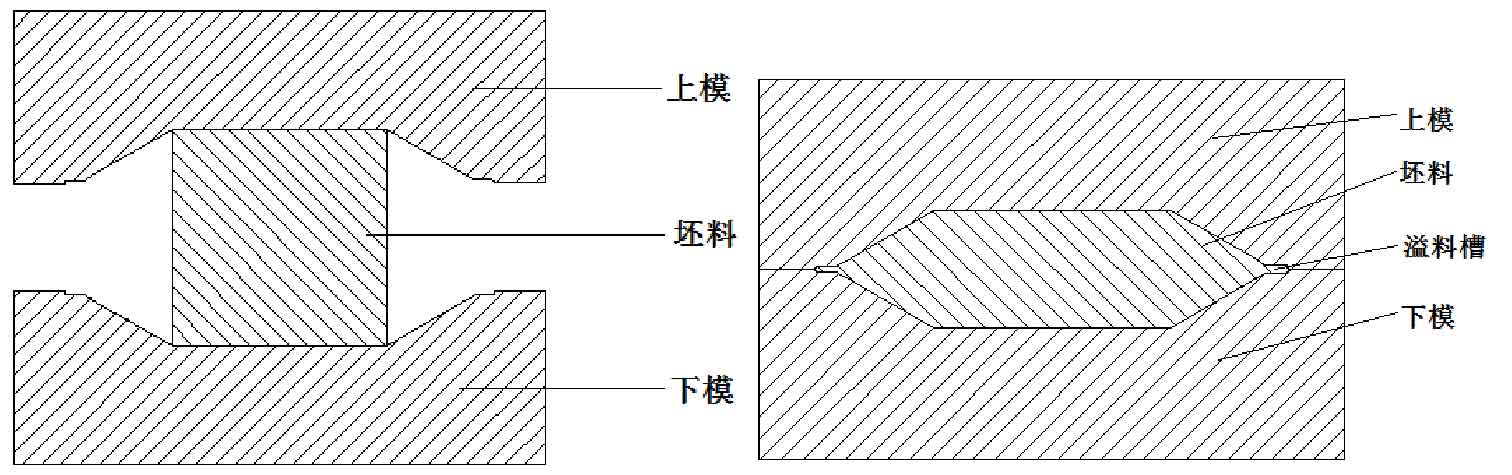

The precision forging process adopted is open die forging, as shown in the figure is the schematic diagram of open die forging. Die forging refers to the forging method of forging by forming the blank with the die on the special die forging equipment. The spiral bevel gear forgings produced by this method have accurate dimensions, small machining allowance and can be forged into forgings with complex shapes. The forging streamline inside the forgings is distributed according to the contour of the forgings, which improves the mechanical properties and service life of the spiral bevel gear and has high productivity. It is suitable for mass production; However, the die cost is high and special die forging equipment is required, which is not suitable for single piece or small batch production. Open die forging refers to a die forging method in which the material is not completely limited to the flow in the die bore by designing a flash groove that can accommodate excess metal.

Due to the complex structure of the driven spiral bevel gear of the automobile rear axle and the difficulty in forming the tooth shape, although the closed die forging does not produce flash, it has high requirements for the volume of blank metal and is not easy to control. If the volume of the blank is too small, it is easy to cause dissatisfaction with the filling of the tooth shape part, resulting in processing defects; If the blank volume is too large, it is easy to cause the expansion and crack of the die, damage the die and affect the service life of the die. Compared with closed die forging, open die forging has less deformation resistance and forming force, which is easy to form complex forgings such as spiral bevel gear of automobile rear axle.