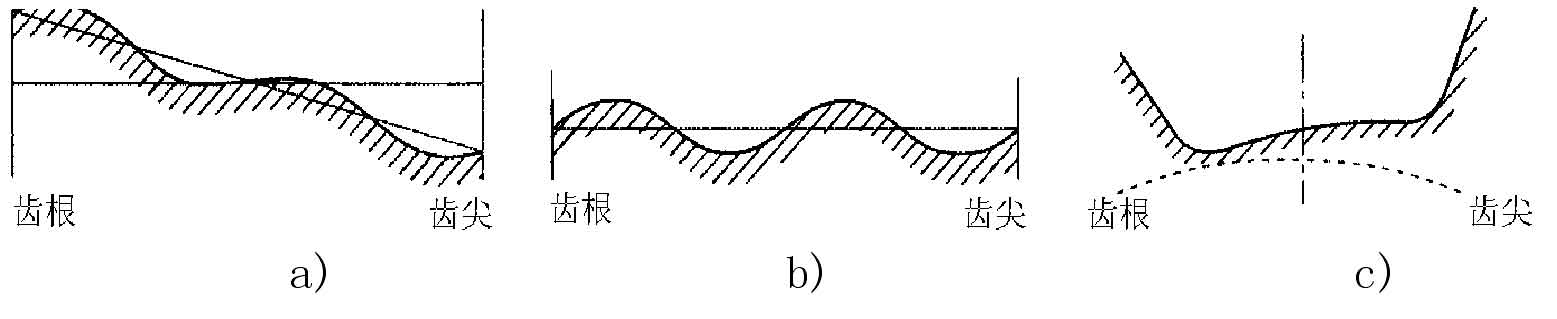

The influence of gear hobbing hob accuracy on machining accuracy is shown in the figure. 100% of the total meshing error on the full length of the meshing line in figure a is reflected in the tooth profile error, 100% of the error on any circle of the spiral line of the gear hobbing hob in Figure B is reflected in the tooth profile error, and 20% of the radial runout error on the tooth top of the gear hobbing hob in Figure C is reflected in the error of the work piece.

The practice of automobile gear machining shows that the tooth thickness error of gear hobbing hob can cause the error of gear tooth thickness; The tooth thickness error of gear hobbing hob can cause 100% impact on the tooth root diameter. If the gear hobbing hob is a top cutting and semi top cutting tool, it will also affect the top circle diameter of gear and the size of tooth top chamfer; 100% of the tooth profile error of gear hobbing hob is transformed into the tooth profile error of gear; The cumulative error of groove rake face of gear hobbing hob causes the tooth profile error of gear, which will be equivalent to 10% of the error value of the tool; The error value caused by the axial lead error of 100 mm long front edge of gear hobbing hob is 10% of the error of generating area; The radial runout of the two shafts of the gear hobbing hob will cause the tooth profile error of the gear, and the error value accounts for 30% of the gear runout error.

At the same time, the axial runout of the two end faces of the gear hobbing hob will cause the tooth profile error of the gear, and the error value is 100% of the runout error; The shape and position error of the front edge of gear hobbing hob affect the tooth profile error of gear, especially the pressure angle error. 10% of the error will be converted to the tooth profile error of gear.