Due to the condition control of biting in and rolling through of spiral gear blank, the ring wall is too thick or too thin, which is not conducive to the smooth progress of ring rolling. In order to realize ring rolling forming and meet the above two basic conditions, there is a limit range of spiral gear blank wall thickness.

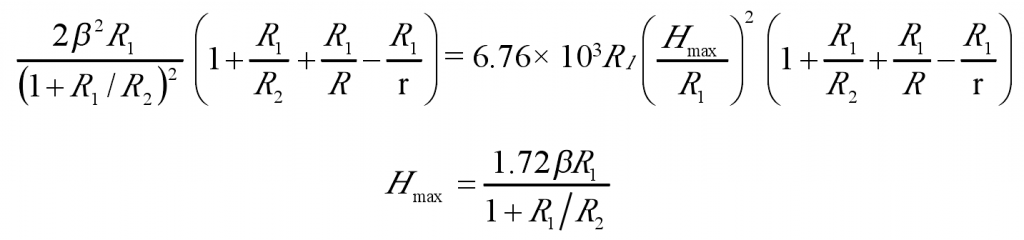

It can be seen from the formula that increasing the wall thickness of the ring will lead to the minimum feed per revolution Δ Hmin also increases accordingly. When the minimum feed per revolution of rolling is equal to the maximum feed of spiral gear blank biting, the wall thickness reaches the maximum limit, and increasing the wall thickness can not meet the above two conditions. order Δ hmin= Δ Hmax, substitute R-R = Hmax into the formula to obtain the maximum thickness of the ring:

In addition, if the wall thickness of the spiral gear blank is too thin, it will be flattened by the guide roll because its hardness is not enough, and the forming is not circular. Therefore, the determination of the minimum wall thickness of the spiral gear blank is based on the strength conditions of the materials used.