According to the characteristics of cold and closed bevel gear finishing, two schemes of cold and closed bevel gear finishing are put forward respectively.

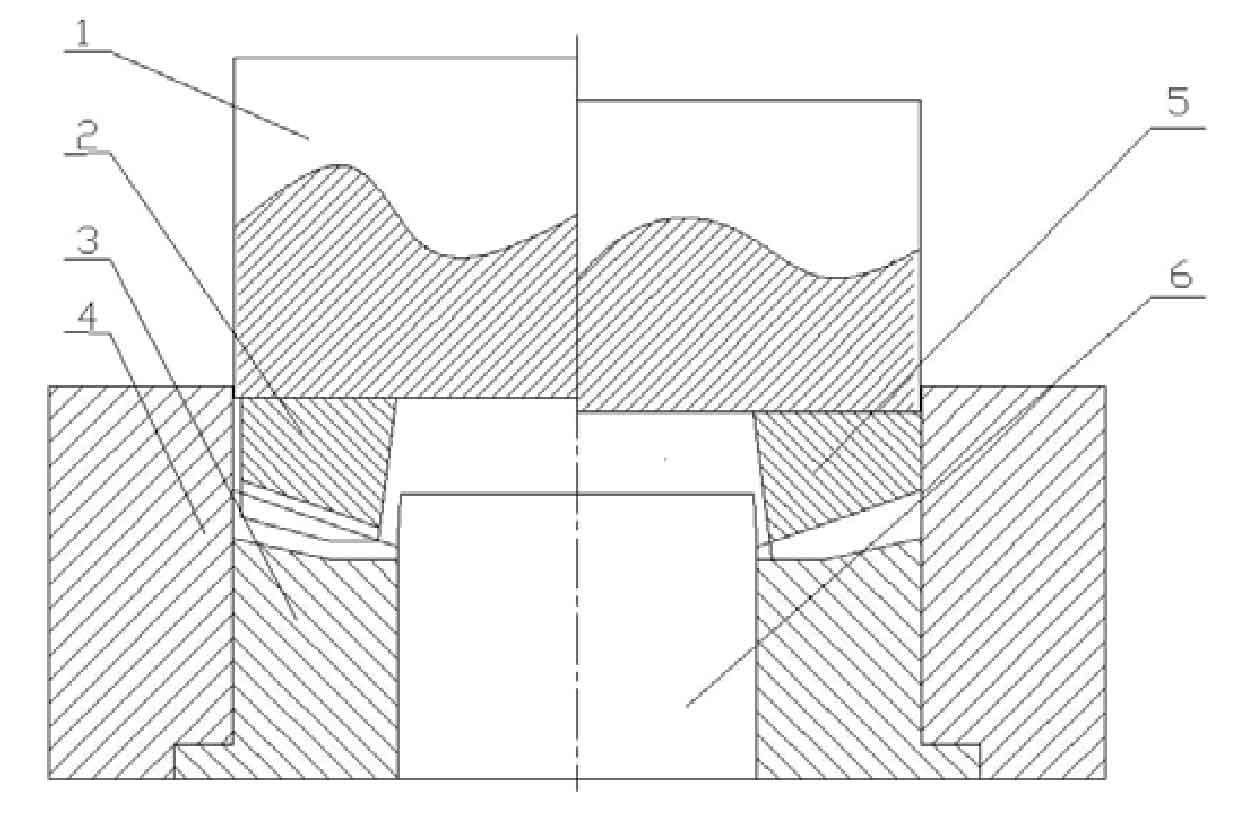

1. Finishing scheme I: closed cold finishing

According to the characteristics of forming, the die structure is designed as shown in Figure 1. The hydraulic press pushes the upper punch to move downward and transmits the pressure it bears to the spiral bevel gear tooth blank. The tooth part of the spiral bevel gear tooth blank contacts the tooth part of the concave die and is subjected to the pressure of the punch, resulting in plastic deformation of the metal in the tooth part. Part of the metal material flows to the tooth root of the concave die tooth shape, and part flows to the big end and small end of the concave die tooth shape, and finally fills the cavity of the concave die tooth shape, The defects such as oxidation, crack, pit and Overburning of the tooth profile of the spiral bevel gear are effectively eliminated, reaching or approaching the required specifications and dimensions of the parts.

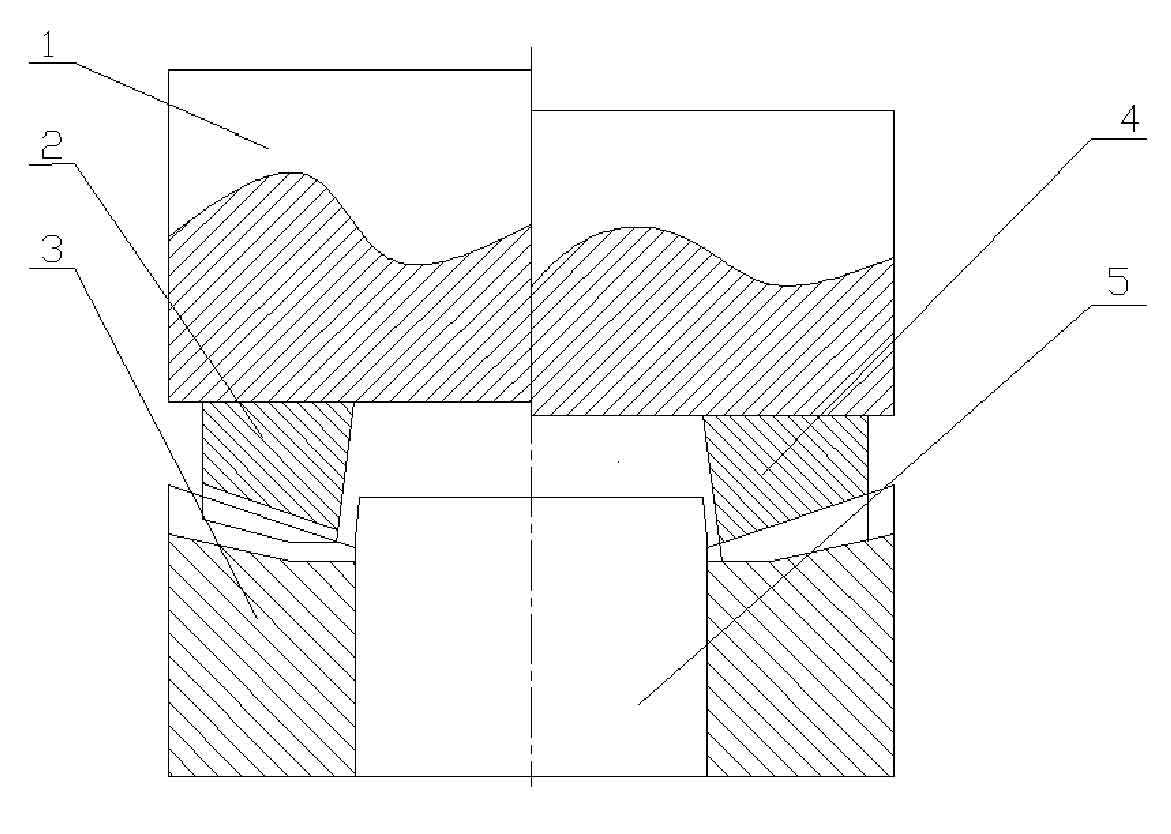

2. Finishing scheme II: open type cold finishing

The process scheme of open cold finishing is shown in Figure 2. Different from the closed cold finishing, when using the open cold finishing scheme to finish the tooth blank of spiral bevel gear, because it is not hindered by the die, the metal material at the tooth part of spiral bevel gear can flow radially to the big end and small end of the tooth shape of female die, which can effectively prevent the accumulation of materials and alleviate the sharp rise of forming force.