This comprehensive study delves into the fracture failure analysis of a bevel gear that experienced abnormal failure during operation. Employing various analytical techniques, including macroscopic fracture morphology observation, elemental spectroscopic analysis, metallographic microstructure analysis, non-metallic inclusion analysis, surface and matrix hardness testing, and surface hardening layer depth measurement, we aim to identify the root causes of the gear’s failure. Our findings reveal that the presence of deep non-martensitic microstructure on the gear’s surface significantly reduced its hardness, wear resistance, and overall fatigue limit, ultimately leading to catastrophic failure.

Introduction

Bevel gears play a crucial role in automotive drivetrains, specifically in the main reducer system. They facilitate the reduction of rotational speed, increase torque, and redirect the rotation axis. The effectiveness of these gears is paramount for smooth and efficient vehicle operation. However, premature failures can disrupt the system’s functionality and lead to significant downtime and repair costs.

In this study, we analyze a bevel gear that failed prematurely, well before its expected service life. The aim is to identify the underlying mechanisms contributing to the failure and propose corrective measures to prevent future occurrences.

Background on Bevel Gear Manufacturing and Processing

Bevel gears undergo a rigorous manufacturing process that involves multiple steps, including forging, heat treatment, and precision machining. The initial forging shapes the raw material into the desired gear blank. Subsequent heat treatment steps, such as normalizing, quenching, and tempering, improve the material’s mechanical properties and hardness. Finally, precision machining ensures dimensional accuracy and surface finish essential for smooth and efficient gear meshing.

Materials and Methods

To conduct a comprehensive failure analysis, we employed a multi-faceted approach encompassing macroscopic and microscopic inspections, chemical composition analysis, hardness testing, and metallographic examination.

1. Macroscopic Fracture Morphology Observation

Upon visual inspection, it was evident that most of the gear teeth had fractured, and macroscopic cracks were present on the remaining undamaged teeth roots. Two distinct fracture surfaces exhibited characteristic “beach marks,” indicative of low-cycle fatigue failure. These marks signify the progression of fatigue cracks from their origins to ultimate failure.

2. Chemical Composition Analysis

Using a direct-reading spectrometer, we analyzed the chemical composition of the gear material, confirming it to be 20CrMnTiH steel. The elemental analysis results are presented in Table 1, showing compliance with the GB/T 3077-2015 standard for alloy structural steel.

Table 1: Chemical Composition of the Bevel Gear (Mass Fraction)

| Element | C | Si | Mn | P | S | Cr | Ti | Cu | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.22 | 0.33 | 0.65 | 0.015 | 0.016 | 1.06 | 0.056 | 0.058 | 0.029 |

3. Hardness Testing

Rockwell hardness measurements were performed on both the surface and the matrix of the gear. The results, summarized in Table 2, reveal that the surface hardness was uneven and lower than the design specification (58-64 HRC). The matrix hardness was close to the design requirement’s lower limit.

| Sample | Surface Hardness | Matrix Hardness |

|---|---|---|

| 1 | 53.3 | 32.7 |

| 2 | 58.9 | 32.3 |

| 3 | 59.2 | 33.2 |

| 4 | 54.1 | 32.1 |

| Mean | 56.4 | 32.6 |

4. Surface Hardening Layer Depth Measurement

The effective case hardening depth was measured using a micro-Vickers hardness tester. The average depth of 0.86 mm (within the specified range of 0.8-1.1 mm) indicates compliance with the design requirements.

5. Metallographic Analysis

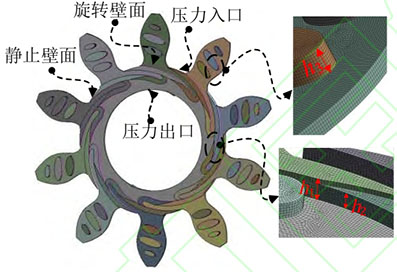

Metallographic specimens were prepared from the fractured tooth region and polished for microscopic examination. No significant non-metallic inclusions were found, confirming their non-contributory role in the failure. However, a non-martensitic microstructure was observed on the surface of the fractured tooth root, extending approximately 0.04 mm deep (Figure 1). This non-martensitic layer significantly compromises the gear’s mechanical properties.

Results and Discussion

1. Fracture Mechanism

The presence of a deep non-martensitic layer on the gear’s surface is the primary cause of the premature failure. This microstructure results from inadequate heat treatment, specifically related to the quenching and carburizing processes. The non-martensitic phase exhibits inferior mechanical properties, including reduced hardness and fatigue resistance.

Fatigue cracks initiated at the grain boundaries or stress concentrators, such as oxides, and propagated rapidly along the grain boundaries. This process led to the surface fracture and a significant reduction in the gear’s bending strength.

2. Hardness Inhomogeneity

The uneven hardness distribution across the gear surface, as evident from the hardness test results, further exacerbates the problem. The lower surface hardness values, coupled with the non-martensitic microstructure, create a conducive environment for fatigue crack initiation and propagation.

3. Non-Metallic Inclusions

While non-metallic inclusions were not identified as the primary cause of failure, their presence can still contribute to localized stress concentrations and facilitate crack initiation under certain conditions.

Corrective Measures

To mitigate future failures, the following corrective measures are proposed:

- Improve Heat Treatment Processes:

- Enhance the cleanliness of the carburizing atmosphere by strictly controlling the sealing of the heat treatment furnace and extending the exhaust time to eliminate potential oxidizing agents.

- Adjust the quenching and cooling rates to optimize the martensitic transformation and minimize the formation of non-martensitic phases.

- Surface Hardness Enhancement:

- Ensure the workpiece surface is thoroughly cleaned before carburizing to improve the adhesion of the carburized layer.

- Increase the surface hardness to enhance the gear’s resistance to contact fatigue and wear.

- Material Selection and Process Control:

- Consider using alloys with optimized compositions that minimize the formation of non-martensitic phases during heat treatment.

- Implement rigorous quality control measures throughout the manufacturing process to identify and rectify any deviations from standard operating procedures.

Conclusion

Through a comprehensive failure analysis, we have identified the primary cause of the bevel gear’s premature failure as the presence of a deep non-martensitic microstructure on its surface. This microstructure significantly compromises the gear’s mechanical properties, leading to fatigue crack initiation and propagation. The proposed corrective measures aim to optimize the heat treatment processes, enhance surface hardness, and improve material selection and process control. These measures are expected to significantly reduce the likelihood of future failures and extend the gear’s service life.

Continued Analysis and Improvement Measures

4. Further Analysis of Failure Mechanisms

In addition to the existence of deep non-martensitic microstructure on the gear surface, the low surface hardness and non-uniformity further exacerbate the problem. The combination of these factors leads to premature fatigue crack initiation and rapid crack propagation, ultimately resulting in catastrophic gear failure.

Moreover, the presence of shallow oxide inclusions, though not the primary cause of fracture, can act as stress concentrators, exacerbating the fatigue process. The fact that these oxides were observed in the vicinity of the fracture site further supports the hypothesis that stress concentrations played a significant role in initiating and propagating the cracks.

5. Effectiveness of Improvement Measures

To mitigate the issues identified, the following corrective actions were implemented:

(1) Enhancing Furnace Atmosphere Purity: By improving the sealing of the heat treatment furnace and extending the exhaust time, the purity of the carburizing atmosphere was significantly increased. This helped to reduce the formation of non-martensitic microstructures on the gear surface, thereby enhancing surface hardness and wear resistance.

(2) Improving Surface Hardness Uniformity: Ensuring proper surface cleanliness prior to carburizing helped achieve a more uniform carburizing layer depth and hardness distribution. This, in turn, improved the overall fatigue resistance of the gear.

(3) Modifying Quenching Cooling Process: By increasing the quenching cooling rate, particularly at the gear root where non-martensitic microstructures tend to form, the formation of these undesirable microstructures was minimized. This modification was crucial in improving the bending strength and fatigue life of the gear.

6. Post-Improvement Verification

After implementing the above-mentioned improvements, a new batch of gears was subjected to rigorous testing. Macroscopic and microscopic examinations revealed a marked reduction in the presence of deep non-martensitic microstructures on the gear surfaces. Additionally, the surface hardness and uniformity were found to be within the specified limits.

Dynamic fatigue testing was also conducted to evaluate the long-term durability of the gears under simulated operating conditions. The results indicated a significant improvement in fatigue life, confirming the effectiveness of the implemented corrective actions.

7. Conclusion

This case study underscores the importance of comprehensive failure analysis in identifying the root causes of premature component failure. By employing a multi-faceted approach that combines macroscopic, microscopic, and chemical analyses, we were able to pinpoint the specific defects responsible for the gear failure. Subsequently, targeted improvements to the heat treatment process led to a marked enhancement in the performance and reliability of the gears.

Future work could involve further optimization of the heat treatment parameters and a closer monitoring of the process variables to achieve even higher levels of quality control and product consistency. Overall, this study provides valuable insights into the mechanisms of fatigue failure in automotive gears and offers practical solutions for mitigating such failures in industrial applications.