The new imported ocean going freighter has been in operation for 36 days from trial run to service. During the normal voyage, the gearbox gear shaft broke suddenly on December 19. The diameter of the gear part is φ = 500mm, the tooth width is 360mm, and the gear shaft is broken into two sections along the radial direction in the middle part of the gear.

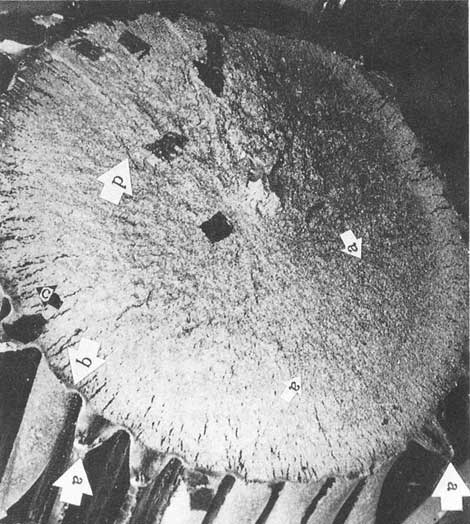

The gear shaft material is 20CrMnMo steel. According to the information provided by foreign manufacturers, the gear shaft is forged as a whole and its surface is hardened. The fracture position is shown in Fig. 6, and the macro fracture is complete. It can be seen that the gear shaft is fatigue fracture with obvious fatigue mark on the teeth, which is the amplification of the teeth indicated by the big arrow A in Fig. 7.

The fracture of the gear shaft is mainly caused by the poor quality of the material itself. Metallurgical defects such as forging internal crack, structure segregation, inclusions along the crystal distribution are the main causes of brittle fracture. When the tooth surface is alloyed, the insufficient structure stress after quenching and tempering, and the insufficient elimination of the thermal stress during heat treatment are also the important factors causing the cracks. Under the action of internal and external stress, the casting defects that have not been eliminated are easy to become propagation cracks, so the tooth part first produces fatigue, and then there are as many as 100 internal cracks in the gear shaft, so the instant brittle fracture occurs rapidly.

The broken part is indicated by the white arrow. The black arrow refers to that after the fracture of the gear shaft, the parts in the gear box collide with each other, so that the teeth are deformed, twisted and broken. The broken gear and journal are a whole, and the diameter of the big gear without damage is about 800mm, which is fastened together with the journal as a “red sleeve”. The part shown in the picture weighs about 2 tons.

Macroscopical view of fracture. There are macroscopic fatigue features in the range indicated by arrow A, especially in the teeth indicated by large arrow A, and primary fracture features in other areas. Arrow B refers to the hardened layer of gear heat treatment. Arrow C refers to radial steps, almost covering the whole gear circumference, which is the expression of stress concentration, and arrow D refers to internal cracks. The whole macro fracture shows a great tendency of brittleness.

The macroscopic appearance of teeth with obvious fatigue characteristics. Fatigue originates along the hardened layer or transition zone, as indicated by the white arrow. Due to the collision after the fracture of the gear shaft, the hardened layer in the area indicated by the arrow has collapsed. The direction of fatigue crack growth is indicated by the black arrow.