Introduction

The aviation high-speed gear pump is an important power output device in the aircraft hydraulic system. In order to meet the development needs of high thrust to weight ratio and low fuel consumption in aircraft, it is required to increase the flow rate of the gear pump without increasing its volume and mass. Therefore, it needs to be designed for higher speeds. However, high-speed increases the wear of the gear end face friction pair of the gear pump, reduces its service life and volumetric efficiency, and in severe cases, can affect the stable and reliable operation of the aircraft hydraulic control system.

Domestic and foreign scholars have conducted research and analysis on the frictional characteristics of gear pump friction pairs, in order to grasp their wear and tear

Mechanism and control methods. Establish a three-dimensional gear pump model and obtain the time-dependent liquid film pressure on the gear end face The law of change. Theoretical and experimental research has been conducted on gear pumps, and the results show that an increase in outlet pressure can cause tooth damage The fluctuation of the flow field inside the wheel pump exacerbates the wear of the gear end face. Establishment of gear pump based on thermal fluid solid coupling method The coupling model of gear end face friction pair shows that the end face oil film pressure decreases along the circumferential direction and eccentric wear mainly occurs in the low-pressure area of the oil film. Taking the high-pressure gear pump as the research object, it was found that the tilting moment caused by the asymmetric distribution of pressure in the gear working chamber leads to the tilting of the floating side plate, which is one of the important reasons for end face wear. In order to improve the lubrication conditions of gear end faces, a new asymmetric balanced gear pump end face lubrication fluid structure coupling model is established. By determining the balance area on the floating side plate, optimal axial balance is achieved. A gear friction pair axial motion coupling model is proposed, which reduces the end face wear and friction power consumption of the friction pair by optimizing the floating side plate structure. From this, it can be seen that insufficient lubrication of the gear end face friction pair is the main cause of end face wear during high-speed operation of the gear pump. Improving lubrication through reasonable design of the friction pair structure is one of the important ways to increase the service life.

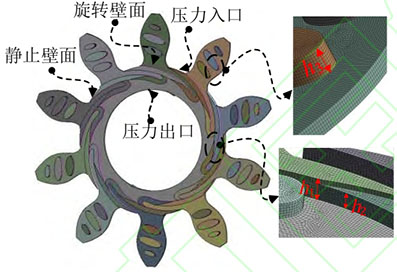

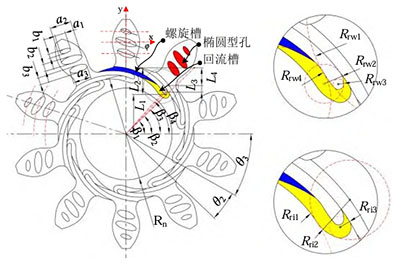

Surface texture can effectively improve friction and wear problems, but there are few reports on its application in gear pump gear end face friction pairs. Based on the excellent comprehensive performance of Tesla like valve grooves and elliptical grooves, and considering the special structural characteristics of the gear end face of the gear pump, which is a continuous end face with a circular ring on the inner end face and a discontinuous end face with protruding teeth on the outer end face, in order to effectively utilize the area of the gear end face, Tesla like valve grooves are designed on the continuous end face of the gear ring, and elliptical holes are designed on the discontinuous end face with protruding teeth, forming a composite texture of Tesla like valve grooves and elliptical holes. Systematically study the lubrication characteristics of gear end face composite textured friction pairs under different operating conditions, compare and analyze the opening force and leakage rate of textured end faces under different operating conditions and structural parameters, and provide theoretical reference for the design and application of lubrication textures on gear end faces of high-speed external gear pumps.

Friction pair structure of gear pump end face

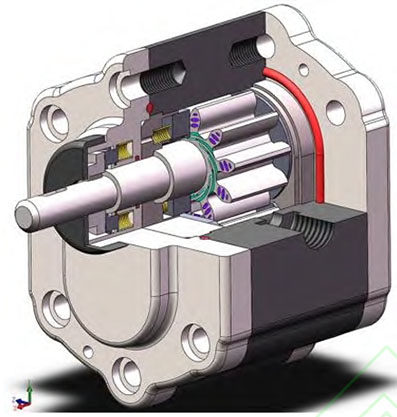

A three-dimensional structural sectional view of a high-speed external gear pump was created with a Tesla like valve groove elliptical hole composite texture on the gear end face. Schematic diagram of the cross-section of the gear end face friction pair, from which it can be seen that the gear The friction pair that forms relative motion with the floating side plate, when the gear rotates at high speed, under the action of the hydrodynamic pressure effect of the lubricating texture fluid, a micrometer thick lubricating liquid film will be formed between the gear end face friction pair. In order to achieve good sealing and non-contact operation of the gear end face friction pair, it is necessary to control the design film thickness within an appropriate range. To achieve this goal, advanced laser etching technology is needed to ensure the accuracy of groove depth machining as much as possible. On the other hand, the actual machining situation needs to be considered. Based on the measured groove depth and mechanical balance, reverse design is required Calculate the theoretical equilibrium film thickness.

conclusion

(1) Setting up dynamic pressure lubrication texture on the end face can not only effectively open the end face by increasing the fluid film pressure, but also make the pressure distribution more uniform along the circumferential direction, which has a positive effect on improving the stability of liquid film support and reducing end face eccentric wear.

(2) Compared with the non textured gear end face liquid film, the operating parameters such as film thickness, outlet pressure, and rotational speed have a greater impact on the opening force and leakage rate of the textured end face liquid film; Under high-speed and high outlet pressure conditions, the textured end face can ensure that the gear end face friction pair has better leakage control and lubrication performance.

(3) Within the scope of studying the working conditions and structural parameters in this article, in order to ensure that the high-speed gear pump gear end face friction pair has both excellent opening and leakage control properties.