This article presents a detailed study on gear transmission and a significant property of node acceleration. It begins by introducing a kinematic problem involving gear meshing transmission, then solves it using both geometric and analytical methods. The errors in the original solution are identified. A crucial conclusion is put forward: regardless of whether a gear or a rack is in fixed-axis rotation or general planar motion, the projections of the respective nodes’ accelerations along the direction of the common tangent of the nodes are equal. This holds true for cylindrical gear transmission, including gear-rack transmission. Additionally, the article emphasizes the importance of caution when teachers and students select relevant example and exercise solutions due to the abundance of incorrect information on the Internet.

Introduction

Gear transmission is a common mechanical phenomenon that plays a vital role in various machines and devices. Understanding the motion and acceleration characteristics of gears is essential for the design and analysis of mechanical systems. In this article, we will explore a problem related to gear meshing transmission and introduce a key property of node acceleration.

Problem Description

A PPT document titled “Rigid Body Planar Motion Exercise Class” contains a problem as follows: A rack AB drives a gear with a radius of r = 5 cm to pure roll on a horizontal rack, and point A of the rack moves at a constant linear velocity of vA = 30 cm/s. When the angle θ is 60 degrees, it is required to find the angular velocities and angular accelerations of the gear and the rack.

Original Solution and Its Errors

The original paper provides the following results: ωwheel = 2 rad/s (ω), ωAB = 2 rad/s (ω), αwheel = 8√3 / 3 rad/s² (∼), and αAB = 0 rad/s². However, in the process of solving this problem, the author 混淆了 the acceleration of point D on the gear with that on the rack AB, leading to incorrect results. The fundamental reason for this error is the confusion between hinge connection and gear-rack meshing transmission, or, from the perspective of kinematics of mechanisms, the confusion between rotating pairs and gear-rack pairs.

Detailed Discussion

1. Gear Transmission Basics

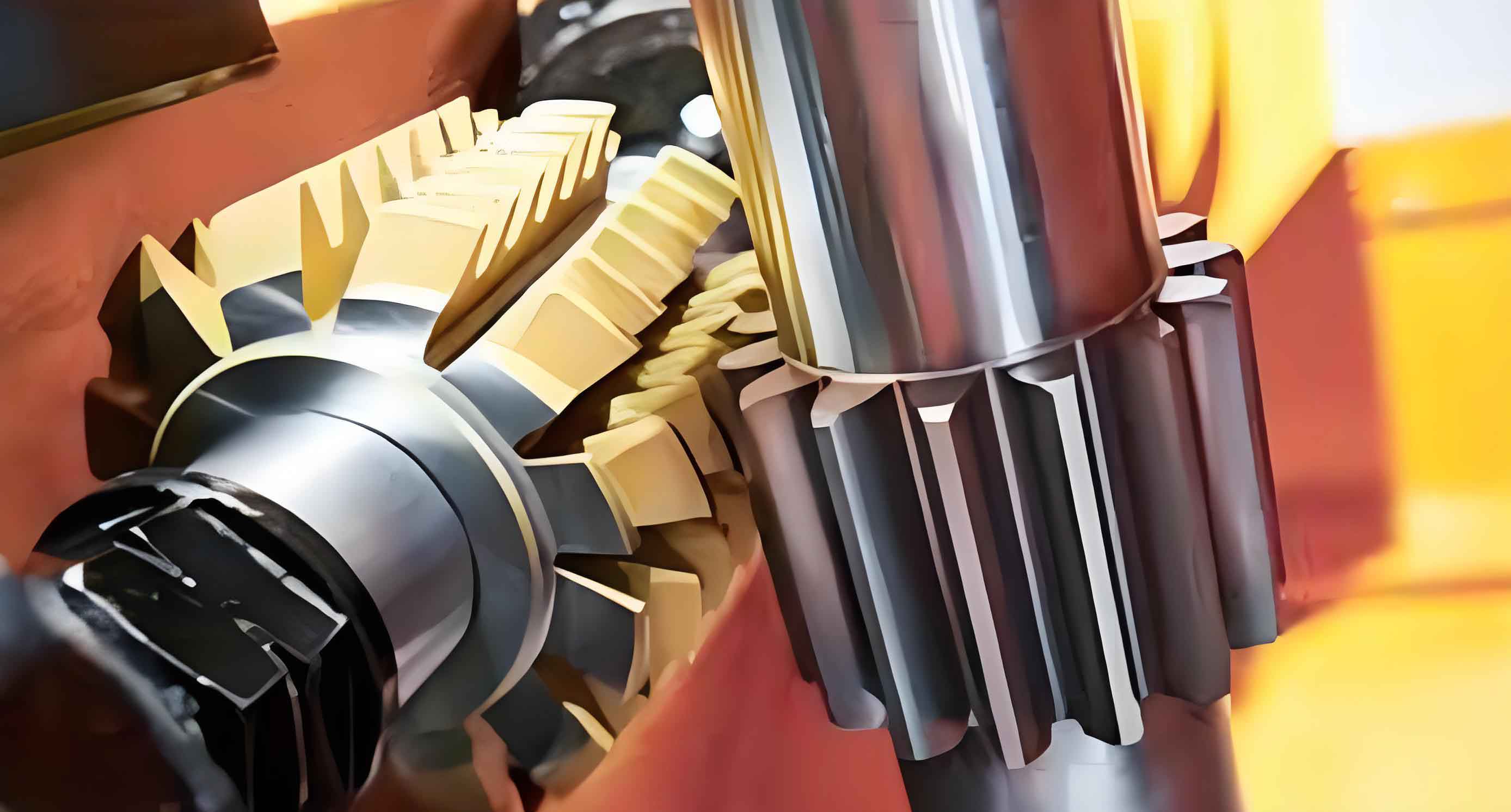

The meshing process of gear transmission involves relative sliding between the gear teeth. However, the intersection point of the common normal of the two tooth profiles at any meshing point and the line connecting the two centers remains unchanged. This point is called the gear transmission node. The projection of the gear transmission node on the gear plane is called the gear node, and the motion trajectory of the gear node is called the pitch circle. The pitch circles of the two gears are tangent to each other at the gear transmission node, and the velocities of the two nodes are equal. Therefore, the meshing transmission of the two gears can be regarded as the pure rolling of the two pitch circles. A rack can be seen as a gear with an infinitely large radius. When gear-rack meshing transmission occurs, the pitch circle of the rack becomes a pitch line. Thus, the meshing transmission between a gear and a rack can be considered as the pure rolling of the gear pitch circle and the rack pitch line.

2. Geometric Method for Solving Angular Velocities and Angular Accelerations

- Finding Angular VelocitiesThe gear rolls purely on the horizontal rack, meaning both the gear and the rack AB are in planar motion. Point D in the figure is the gear-rack transmission node, with the node on the rack labeled as D1 and the node on the gear as D2, where the velocities of these two points are equal, i.e., vD1 = vD2. As the gear rolls purely on the horizontal rack, point M is the instantaneous center of velocity of the gear. Therefore, the velocity directions of D1 and D2 are known. By drawing the extension of MD and the perpendicular of vA, the instantaneous center of velocity P of the rack AB can be obtained (see Figure 2). Then, we have ωAB = vA / PA = vA / (2MD cos 30°) = 30 / (2 × 5√3 × √3 / 2) rad/s = 2 rad/s (ζ). The velocity vD1 = PD × ωAB = 5√3 × 2 cm/s = 10√3 cm/s. And ωwheel = vD2 / MD = vD1 / MD = 10√3 / 5√3 rad/s = 2 rad/s (v).

- Finding Angular AccelerationsTaking the gear node D2 as the moving point and the rack AB as the moving reference body, according to the synthetic acceleration theorem of point motion, we have aD2 = ae + ar + ak. Since the node D1 of the rack is the entrainment point of the moving point D2, then ae = aD1. So, aD2 = aD1 + ar + ak (1), where ar is the acceleration of the node D2 relative to the rack AB. The motion of the gear relative to the rack AB is actually the pure rolling of the gear on the rack AB, and the node D2 is the instantaneous center of velocity of the gear’s relative motion, so the magnitude of the relative acceleration of the node D2 is ar = rωr², with the direction pointing from D2 to the gear center C. The calculation of ωr, the angular velocity of the gear relative to the rack, is easily overlooked. Because the angular velocity of the gear and the angular velocity of the rack AB have opposite directions, ωr is not the subtraction of the two but the addition, that is, ωr = ωwheel + ωAB = (2 + 2) rad/s = 4 rad/s (ω). ak is the Coriolis acceleration of the node D2. Since the velocities of the node D2 on the gear and the node D1 on the rack are equal, the relative velocity vr of D2 relative to the rack AB is 0, then the Coriolis acceleration ak of D2 is also 0, and equation (1) simplifies to aD2 = aD1 + ar (2), establishing the relationship between the accelerations of nodes D1 and D2. Taking the gear as the object and the instantaneous center of velocity M of the gear as the base point to find the acceleration of the node D2 on the gear, we get aD2 = aM + aD2M^n + aD2M^t (3). Taking the rack AB as the object and the end point A of the rack as the base point to find the acceleration of the node D1 on the rack, we get aD1 = aA + aD1A^n + aD1A^t (4). Substituting equations (3) and (4) into equation (2), and noting that aA = 0, we obtain (see Figure 3) aM + aD2M^n + aD2M^t = aD1A^n + aD1A^t + ar (5).On the left side of equation (5), aM is the acceleration of the instantaneous center of velocity M of the gear. Because the gear rolls purely on the horizontal rack, the magnitude of the acceleration of point M is aM = rωwheel², with the direction pointing from point M to the gear center C; aD2M^n is the normal acceleration of the node D2 on the gear around the base point M, aD2M^n = D2M × ωwheel²; aD2M^t is the tangential acceleration of the node D2 on the gear around the base point M, aD2M^t = D2M × αwheel. On the right side of the equation, aD1A^n is the normal acceleration of the node D1 on the rack AB around the base point A, aD1A^n = D1A × ωAB²; aD1A^t is the tangential acceleration of the node D1 on the rack AB around the base point A, aD1A^t = D1A × αAB. Projecting both sides of equation (5) in the x-direction, we get aM cos 60° – aD2M^n cos 30° + aD2M^t cos 60° = aD1A^t – ar (6). Projecting both sides of equation (5) in the y-direction, we get aM cos 30° – aD2M^n cos 60° – aD2M^t cos 30° = -aD1A^n (7). By solving equations (6) and (7) simultaneously, we obtain αwheel = 8√3 / 3 rad/s² (∪) and αAB = 16√3 / 3 rad/s² (ν).

3. Analytical Method for Solving Angular Velocities and Angular Accelerations

Taking θ = 60° as the initial moment of motion, let the rotation angle of the gear at any moment be φ, and the angle between the rack AB and the horizontal rack be θ, and assume that the end A of the rack AB moves at a constant linear velocity. A rectangular coordinate system is established as shown in Figure 4. According to the problem, since point A moves at a constant linear velocity, the motion equation of point A is xA = vAt + √3r = 30t + 5√3 (8). In equation (7), xA is a single-valued continuous function of time t, and obviously xA = 30 cm/s, and xA = 0.

To analyze the motion of the gear and the rack, it is necessary to establish the relationship between the coordinate of point A and the rotation angles φ of the gear and θ of the rack. In the figure, AN and AE1 are two tangents passing through the same point outside the circle, so AE1 = AN = xA – xC. Then, in the horizontal direction, we have xA = xC + r sin θ + AE1 cos θ = xC + r sin θ + (xA – xC) cos θ. Because the gear rolls purely on the horizontal rack, we have xC = rφ, that is, xA = rφ + r sin θ + (xA – rφ) cos θ. After arranging, we get xA (1 – cos θ) = r sin θ + rφ (1 – cos θ) (9).

The motion of point A of the rack can be regarded as the result of the gear’s pure rolling on the horizontal rack and the subsequent pure rolling of the rack AB on the gear. After the relative positions of the gear and the rack AB are fixed, the gear is first rotated clockwise by an angle φ on the horizontal rack, and then the rack AB is rolled counterclockwise on the gear until it intersects the x-axis at point A. Let the angle that the rack AB rolls on the gear be β, then the angle θ between the rack AB and the horizontal rack can be expressed as: θ = π / 3 + φ – β. Let the point of tangency between the rack and the gear move from the initial position D to a general position E, then the arc length D2E2 that the point of tangency on the gear moves is the length D1E1 that the rack AB rolls on the gear, so the angle β that the rack AB rolls on the gear is β = D2E2 / r = D1E1 / r = (xA – xC – √3r) / r = (xA – rφ – √3r) / r. Therefore, the angle θ between the rack AB and the horizontal rack is θ = π / 3 + φ – β = π / 3 + φ – (xA – rφ – √3r) / r. After arranging, we get xA = (π / 3 + √3) r + r (2φ – θ).

Taking the derivative of both sides of the equation with respect to time t, we get xA (1 – cos θ) = rφ (1 – cos θ) + θ (r cos θ + rφ sin θ – xA sin θ) (11). From the initial conditions: θ(0) = π / 3, xA(0) = 5√3, φ(0) = 0, and substituting them along with r = 5 cm and xA = 30 cm/s into the equation, and noting that φ0 = φ(0) and θ0 = θ(0), we obtain φ0 – 2θ0 = 6 (12). Taking the derivative of both sides of the equation with respect to time t and then setting t = 0, we get 2φ0 – θ0 = 6 (13). By solving equations (12) and (13) simultaneously, we obtain φ0 = 2 rad/s (ω) and θ0 = -2 rad/s (ζ), that is, at the initial moment of motion, ωiθ = 2 rad/s (P) and ωAB = 2 rad/s (Q). Taking the derivative of both sides of equation (11) with respect to time t and noting that xA = 0, we get rαφ (1 – cos θ) + θα (r cos θ + rφ sin θ – xA sin θ) + θ² (-r sin θ + rφ cos θ – xA cos θ) + 2rφαθ sin θ – 2xAθα sin θ = 0.

At the initial moment of motion, φ = 0, θ = 60°, xA = 5√3 cm, φ(0) = 2 rad/s, and θ(0) = -2 rad/s. Substituting these values into the equation and noting that αφ0 = αφ(0) and θ0 = θα(0), we obtain αφ0 – 2θ0 = -8√3 (15). Taking the second derivative of both sides of the equation with respect to time t and then setting t = 0, we get 2αφ0 – θα0 = 0 (16). By solving equations (15) and (16) simultaneously, we obtain αφ0 = 8√3 / 3 rad/s² (ν) and θα0 = 16√3 / 3 rad/s² (ω), that is, at the initial moment of motion, αwheel = 8√3 / 3 rad/s² (ν) and αAB = 16√3 / 3 rad/s² (ν), which is consistent with the result of the geometric method.

4. An Important Property of Node Acceleration in Gear Transmission

In gear transmission or gear-rack transmission, the velocities of the nodes are the same, but the accelerations of the nodes are different. The conclusion of this article is as follows: regardless of whether a gear or a rack is in fixed-axis rotation or planar motion, the absolute accelerations of the respective nodes in the direction of the common tangent of the nodes are equal. The proof is as follows:

Suppose there is a meshing transmission between two cylindrical gears. When the radius of one of the gears approaches infinity, it becomes a rack, and the gear transmission becomes a gear-rack transmission. The motion of the gear or the rack can be either fixed-axis rotation or planar motion, as shown in Figure 5. Select the node on one of the gears (referred to as gear 1) as the moving point, let the node of the gear be P1, the radius be r1, and the center of the gear be O1; then select another gear or rack (referred to as gear 2) as the moving reference body. The rack can be regarded as a gear with the center of the gear at infinity, let the node of the gear be P2, and the center of the gear be O2. The moving point is the node P1, and the entrainment point of the moving point P1 is the node P2. According to the synthetic acceleration theorem of point motion, a = ac + ar + ak, where aa = aP1 and ac = aP2, then we have aP1 = aP2 + ar + ak (17). Here, ar is the acceleration of the moving point P1 relative to the gear. The motion of the gear relative to gear 2 is actually the pure rolling of gear 1 on gear 2, let ω be the angular velocity of pure rolling, then the magnitude of the relative acceleration of the moving point P1 is ar = rωr², with the direction pointing from the relative instantaneous center of velocity P1 to the center of the gear O1.

In equation (17), ak is the Coriolis acceleration of the moving point P1. Since the velocities of the node P1 of gear 1 and the node P2 of the gear are equal, the relative velocity vr of P1 relative to the gear is 0, then no matter what kind of motion the gear makes, the Coriolis acceleration ak of the moving point P1 is always 0, so aP1 = aP2 + ar (18). The 连心 line O1O2 is perpendicular to the common tangent t-t of the nodes, and a1 is along the direction of the 连心 line O1O2, so the projection of ar on the common tangent t-t of the nodes is zero. Then, by projecting equation (18) in the direction of the common tangent, we get [aP1] t-t = [aP2] t-t (19).

In general, the direction of the common tangent of the gear transmission nodes is different from the tangent direction of the respective nodes’ motion trajectories, unless both cylindrical gears are in fixed-axis rotation. For the problem presented in this article, by projecting equation (3) or in the direction of BA in the figure, we get [aD1]BA = [aD2]BA = 20√3 cm/s². Although the accelerations of the gear transmission nodes D1 and D2 in the direction of the common tangent of the nodes are equal, their respective tangential accelerations are not equal. By projecting equations (3) and (4) in the direction of the nodes’ velocities, we obtain the tangential accelerations of nodes D1 and D2: aD2^t = -aM cos 60° + aD2M^t = (-20 cos 60° + 40) cm/s² = 30 cm/s², aD1^t = aD1A^n cos 30° + aD1A^t cos 60° = (20√3 cos 30° + 80 cos 60°) = 70 cm/s².

Conclusions