Fatigue is usually caused by repeated and excessive load, which is often broken at or near the root of gear. Fatigue defects may start from small cracks caused by extremely high load, and continue to develop under normal use until gear failure.

The typical fatigue defect of gears is characterized by smooth places. It is caused by heavy load or vibration load (incorrect shifting and clutch operation).

The root fatigue failure of gear teeth occurs.

A fatigue crack extending from the root fillet to the center hole of the gear requires metallographic examination to determine the cause of the defect.

On several teeth of a gear, breakage caused by repeated heavy load. The teeth marked “a” appear to have broken first due to fatigue cracks (pay attention to smooth, velvety areas).

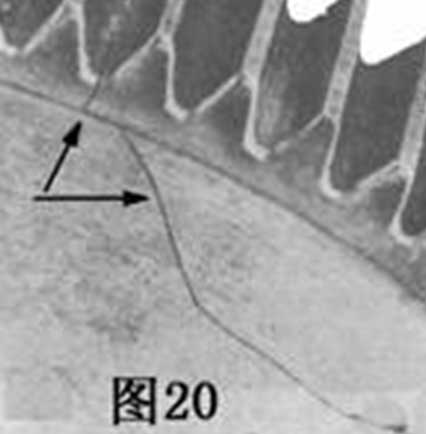

Another case of fatigue fracture. The arrow indicates that the crack begins at the left edge of the fracture, where there is a small pit near the bottom of the meshing area on the compression side of the tooth. The area next to the crack source (arrow) is fully abraded, indicating that the crack initially develops slowly.

The fatigue fracture of the case hardened gear (outer case hardening of the tooth) begins at the root of the tooth and occurs at the joint of the two sides of the tooth (indicated by the arrow) to the middle of the tooth. Metallurgical tests may be required to determine the cause of the defect.

Most of the top teeth of the planet gears have been broken. The stress produced by the working load causes cracks at this point. Finally, perhaps due to fatigue, these cracks continue to develop until the tooth surface. If this happens after a short period of use, it is possible that the surface hardening depth is too large, and metallographic examination is needed to make a judgment.