In the general NC grinding process, when the grinding wheel bears different loads, the cutting force changes accordingly. The change of cutting force will change the output torque of grinding motor, and then lead to the current of grinding wheel spindle motor. Therefore, the grinding wheel load can be monitored by monitoring the current value of the grinding wheel spindle motor in the grinding process, and then the actual grinding feed can be monitored.

The grinding of cylindrical gears can generally be divided into three stages: rough grinding, semi fine grinding and fine grinding. Different grinding parameters are used in different grinding stages. By controlling the grinding current overload of the grinding motor, the cutting capacity and stroke speed of the grinding wheel can be increased as much as possible without grinding burns and grinding cracks, so as to improve the production efficiency.

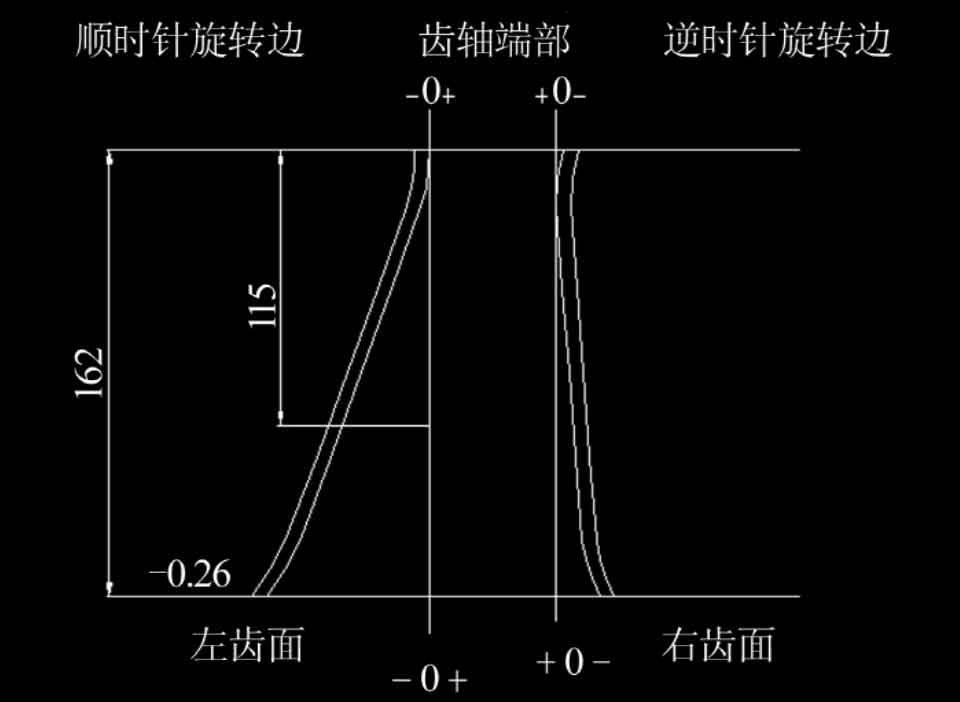

The process research object is carburized and quenched cylindrical gear (see Fig. 1 and Fig. 2). The tooth surface hardness of cylindrical gear is hrc59 ~ 63, the left and right tooth directions are asymmetric, and the tooth root needs to be ground. Materials, equipment and gear grinding procedures of cylindrical gears under normal conditions, about 10% of the products have grinding burns and grinding cracks.

Cylindrical gear grinding adopts rough grinding, semi fine grinding and fine grinding. Rough grinding is mainly to remove the grinding amount, adopt double-sided grinding and radial feed at the same time. Double sided grinding is mainly of high efficiency. In the case of grinding the tooth root, the tooth root circle can be directly processed in place. The disadvantage is that for the cylindrical gears with asymmetric left and right tooth directions, the upper and lower pressure angle deviation is large. Semi fine grinding and fine grinding adopt single-sided grinding, and there is no radial feed during single-sided grinding, so as to improve the accuracy of upper and lower tooth profile angles of cylindrical gears and reduce grinding force. The disadvantage is low efficiency.

The processing equipment is imported form gear grinding machine (see Figure 3), and the inspection and verification means are cylindrical gear tooth surface flaw detection machine and acid pickling inspection equipment. Different brands of grinding wheels are used for process comparison in the research process.