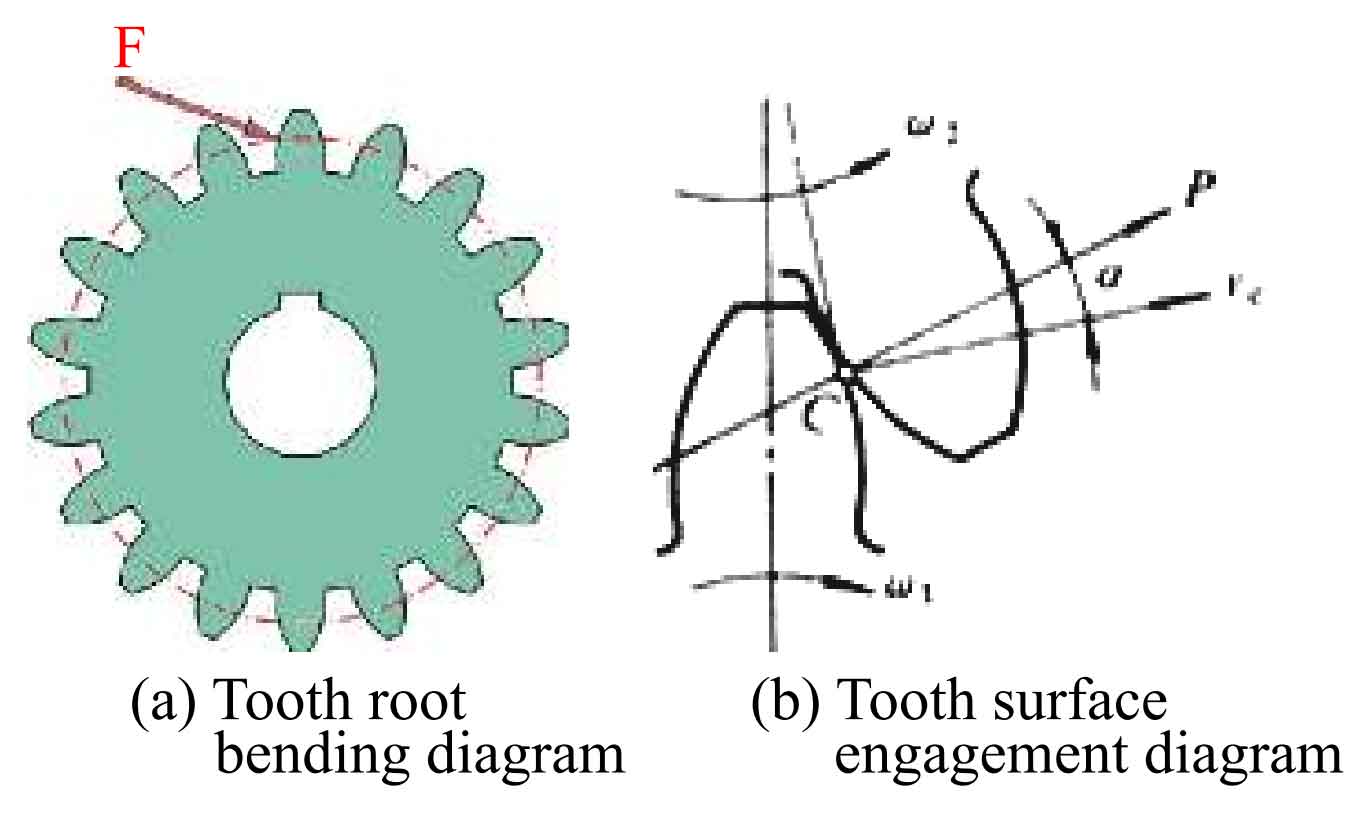

With the advent of China’s high-speed, heavy load, alpine and other models, especially the successful launch of China’s standard EMU, the speed has been increased from 300 km / h to 350 km / h, and the service life has been extended from 20 A to 30 a. the requirements for the stability, reliability and long life of the transmission system are becoming more and more obvious, and more attention has been paid to the steel gear as the core component of the transmission system; Therefore, it is necessary to conduct in-depth research and Discussion on the service life of high-speed steel gears. The stress modes of steel gears are mainly shown in two forms as shown in the figure:

1) Tooth root bending: each tooth can be simplified into a small cantilever beam. When the steel gear is meshed and driven, the bending moment at the tooth root is the largest due to the force.

2) Tooth surface meshing: in the process of meshing transmission, the meshing point changes continuously along the tooth profile, the force and angle of the tooth also change continuously, and the sub surface of the contact surface is subjected to periodic Hertz stress;

Therefore, the common fatigue failure modes of steel gears mainly include tooth root bending fatigue and tooth surface contact fatigue. Tooth surface contact fatigue is the main failure form of closed steel gears, which is also manifested as fatigue pitting and spalling.

There are many kinds of steel gears, which can be classified according to different methods. At present, China’s high-speed iron steel gears are involute helical cylindrical steel gears with good transmission stability. The materials are carburized steel gear steels (18crnimo7-6, 17CrNiMo6, 20CrMnMo, 20CrNi2Mo, etc.), and the final heat treatment process is carburization − quenching − low-temperature tempering. In this way, the steel gears have a hard surface layer (acicular martensite + a small amount of residual austenite + dispersed granular carbide) And tough core (lath martensite). Through comparison, it can be found that the imported Japanese high-speed railway (driven) steel gear adopts high-quality carbon steel s40c surface induction quenching treatment, and the long-term application effect is good, which is worthy of reference and learning by Chinese steel gear workers.

The causes of surface crack defects of s40c steel gear are analyzed. The analysis conclusion can be used as a reference for the research of other types of steel gears with surface hardening treatment.