The heat treatment strengthening technology of automobile gears should pay attention to the control of surface integrity, that is, to control the microstructure, depth, core hardness, residual stress and so on. Improper heat treatment control of automobile gears can easily lead to excessive grain boundary oxide layer structure, decarburization, micro cracks and other heat treatment defects on the surface.

1. Nitrocarburizing

Nitrocarburizing (soft nitriding) has lower treatment temperature than carburizing, which is generally carried out at 460 ~ 600 ℃, so the deformation of automobile gears is small. Nitriding can improve the surface hardness, wear resistance, fatigue strength and corrosion resistance of automobile gears. Japanese automobile companies do not have high requirements on the fatigue life limit of some automobile gears. For automobile gears that do not do tooth surface finish machining after heat treatment, nitrocarburizing process is adopted during heat treatment, which usually aims to improve the wear resistance of automobile gear surface.

2. Surface quenching

Surface quenching mainly includes induction quenching, laser quenching and so on. Compared with carburizing quenching, surface quenching deformation is small. Induction quenching is mainly used for surface quenching of automobile gears. According to the different modules of automobile gears, different ways of induction quenching are adopted. For example, if the module of automobile gears is 3 ~ 5 mm, high-frequency induction quenching is adopted; When the modulus increases to 5 ~ 8 mm, medium frequency induction quenching is generally selected. High frequency heating quenching can obtain the hardening layer evenly distributed along the tooth profile. The fatigue strength of the test piece is greatly improved by using high frequency quenching heat treatment to strengthen the automobile steering pinion. High frequency heat treatment has the outstanding advantages of less CO2 emission, high fatigue strength and wear resistance of automobile gears and less distortion. Laser quenching has the advantages of fine and uniform grains in the quenching area and small deformation of automobile gears. It provides an effective way to strengthen the tooth surface of automobile gears with large modulus and high precision, but its cost is high.

3. Carburizing

Carburizing is one of the widely used chemical heat treatment methods in automobile gear surface treatment. Carburizing treatment can make automobile gears have good comprehensive mechanical properties and effectively prevent gear teeth from breaking. At present, carburizing methods include gas carburizing, vacuum carburizing and plasma carburizing. Gas carburizing is a widely used surface strengthening process for low-carbon alloy steel gears, which can obtain high hardness on the surface of automobile gears and improve their wear resistance, while the core is still the original plate-like martensite structure to maintain good toughness.

High temperature carburizing increases the carburizing temperature of automobile gears from 900 ℃ to 1050 ℃, which can significantly shorten the carburizing time by more than 50%, and effectively improve the production efficiency. However, high temperature carburizing is easy to lead to the coarsening of austenite grains, reduce the fatigue performance of automobile gears, and have large deformation. In order to overcome the problem of grain growth during high temperature carburizing, scholars at home and abroad have found that microalloying is an effective means to inhibit the austenite grain growth of automotive gear steel. The research in Japan shows that the best carburized layer depth and minimum deformation can be obtained by actively controlling the carburizing depth and surface hardness during heat treatment. By adjusting and adding Nb, Ti, B and other alloy elements, the coarsening of austenite grain produced by high temperature carburizing is effectively controlled, and the above problems are better solved. Vacuum carburizing and plasma carburizing have the advantages of no grain boundary oxidation, high surface mechanical properties, less CO2 emission, short heat treatment time and energy consumption, but the cost is high.

4. Carbonitriding

Carbonitriding heat treatment can better improve the strength and wear resistance of automobile gears by effectively mastering the nitrogen concentration and the time node of nitrogen addition. Adopting carbonitriding heat treatment method is conducive to the adjustment of residual austenite content and inhibit the development of initial fatigue cracks to the depth. The thickness of carburized abnormal layer of traditional carburized quenched steel (20CrMoH) is about 15 ~ 20 μ M, the thickness of carburizing abnormal layer treated by carbonitriding is only 1 / 2 of it.

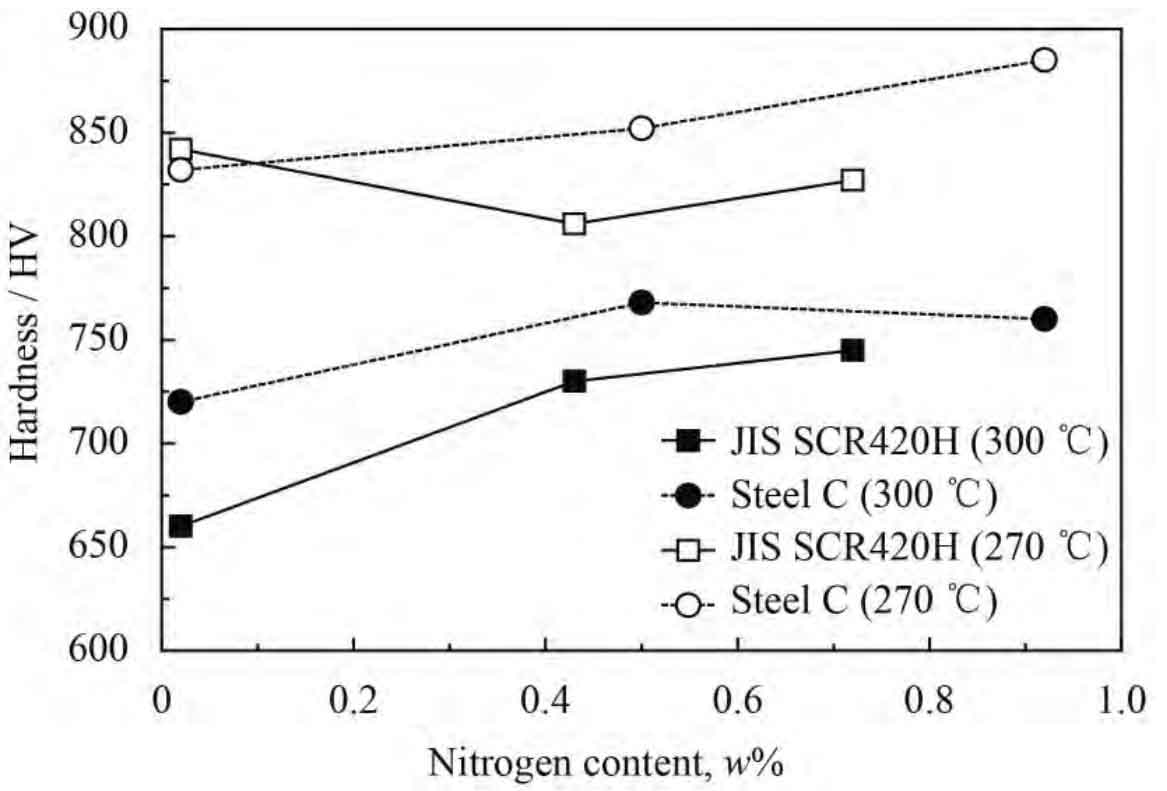

Carbonitriding can effectively improve the depth of carburizing layer, refine austenite grain, reduce automobile gear deformation, and improve automobile gear strength and wear resistance. The actual instantaneous working temperature of the gear meshing surface of carburized automobile automatic transmission is about 250 ~ 270 ℃, which is 150 ~ 200 ℃ higher than the common tempering temperature range. Higher meshing temperature will reduce the hardness of the gear surface and easily produce fatigue pitting corrosion. Adopting carbonitriding process, the tempering resistance can be improved by adjusting the nitriding amount, and the tempering resistance temperature can reach about 300 ℃. As shown in the figure, the effect of nitrogen content on the tooth surface hardness of scr420h steel and Steel C at 170 ℃ and 300 ℃ was studied by carbonitriding process.