This comprehensive article delves into the world of high contact ratio (HCR) spur cylindrical gears and their significant applications in helicopter transmission systems. It explores the technology’s principles, theoretical research, global application scenarios, and the challenges faced in China. Through in – depth analysis and the use of tables for clear presentation, the article aims to provide a thorough understanding of HCR spur cylindrical gears, highlighting their potential to transform helicopter transmission technology.

1. Introduction

In the realm of aviation, the performance and reliability of transmission systems are of utmost importance. Helicopters, with their unique operational requirements, rely heavily on efficient and robust gear systems. Spur cylindrical gears are a fundamental component in these systems. Among them, high contact ratio spur cylindrical gears have emerged as a crucial innovation.

The concept of contact ratio in gears is key to understanding HCR spur cylindrical gears. The contact ratio represents the number of pairs of teeth in contact during the meshing process. For ordinary low contact ratio (LCR) spur cylindrical gears, the contact ratio typically ranges from 1 – 2, meaning only 1 or 2 pairs of teeth are in contact at a time. In contrast, HCR spur cylindrical gears have a contact ratio between 2 – 3, allowing for more teeth to share the load simultaneously. This seemingly small difference brings about significant improvements in gear performance.

2. The Basics of HCR Spur Cylindrical Gears

2.1 Gear Design Principles

HCR spur cylindrical gears are designed using specific methods to achieve a high contact ratio. These include reducing the gear pressure angle, increasing the addendum coefficient, increasing the number of teeth, or modifying the profile shift coefficient. By adjusting these parameters, the contact ratio can be effectively increased.

Reducing the pressure angle widens the base circle, which in turn increases the length of the contact line between the teeth. Increasing the addendum coefficient enlarges the tooth height, allowing more teeth to be in contact. Adjusting the number of teeth and the profile shift coefficient also plays a role in optimizing the contact ratio. However, these design changes also introduce new challenges. For example, a smaller pressure angle and a larger addendum coefficient can lead to a smaller tooth tip width, making the gear more prone to damage during heat treatment processes such as carburizing or nitriding.

2.2 Advantages of HCR Spur Cylindrical Gears

The most notable advantage of HCR spur cylindrical gears is their enhanced load – carrying capacity. With more teeth sharing the load, the load borne by each pair of teeth is relatively reduced. This not only improves the load distribution but also effectively reduces dynamic loads, which is crucial for the smooth operation of helicopter transmission systems.

In addition, HCR spur cylindrical gears contribute to better transmission stability. The reduced vibration and noise levels are highly beneficial for the comfort of passengers and the overall operational environment of the helicopter. Their ability to maintain operation even in the event of tooth loss significantly enhances the safety and damage – tolerance of the transmission system. This is a critical factor in aviation applications, where reliability is non – negotiable.

3. Theoretical Research on HCR Spur Cylindrical Gears

3.1 Gear Strength

Research on the strength of HCR spur cylindrical gears has been an area of active exploration. Currently, there is a lack of literature that uses national or international standards such as ISO to calculate the tooth root stress of HCR spur cylindrical gears. Most scholars rely on experimental methods or finite – element analysis.

3.2 Gear Vibration and Noise

The dynamic performance of HCR spur cylindrical gears, especially in terms of vibration and noise, has also been widely studied. Research has shown that HCR spur cylindrical gears are superior to LCR spur cylindrical gears in noise reduction. When the contact ratio is greater than 2, the vibration amplitude of the gear decreases significantly, and the high – frequency vibration frequency drops remarkably.

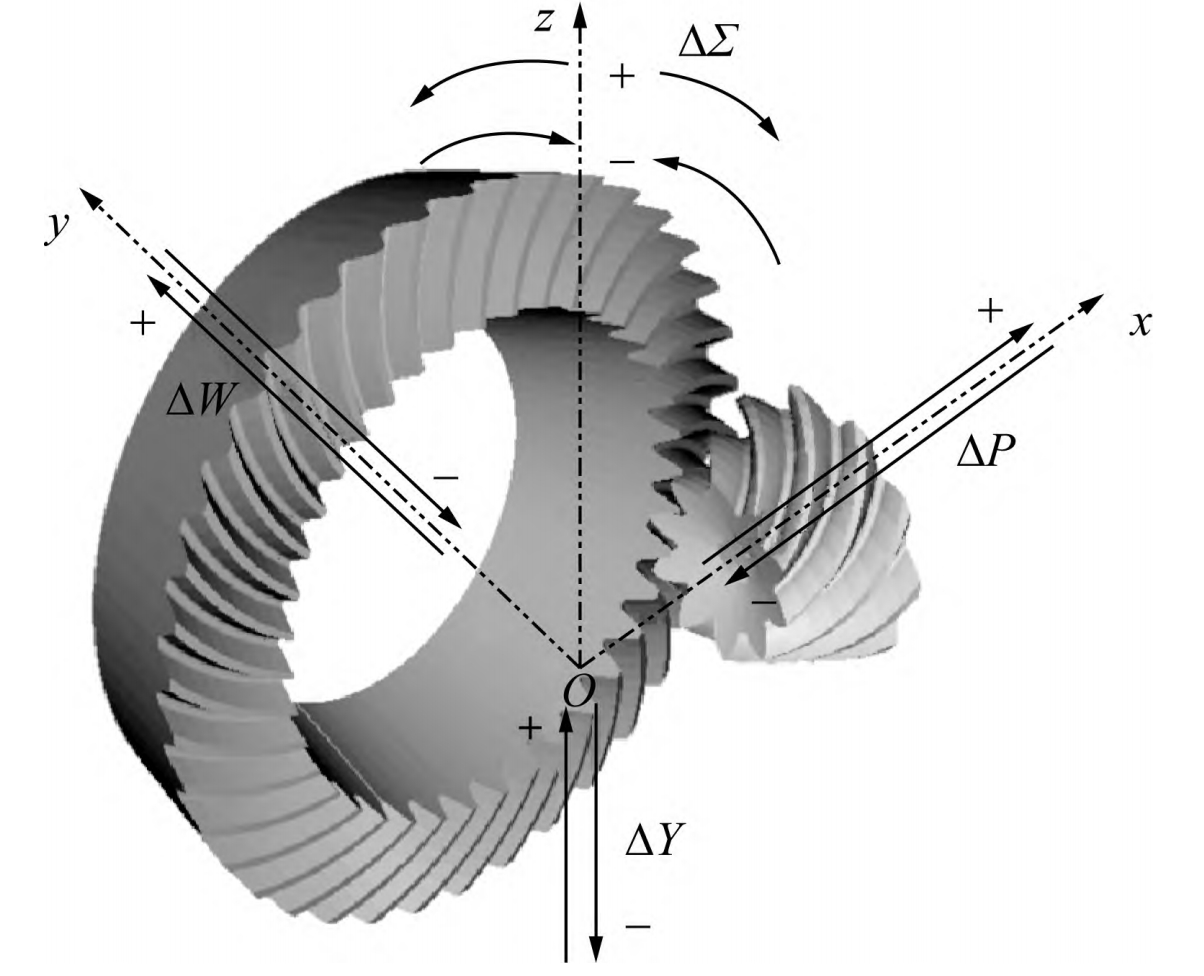

4. Application Research and Progress of HCR Spur Cylindrical Gears in Helicopters

4.1 Applications in Foreign Helicopters

Many world – leading aviation companies have recognized the potential of HCR spur cylindrical gears and have conducted extensive research and applications in helicopter transmission systems.

The American Bell Helicopter Company was one of the first to adopt HCR spur cylindrical gears. In the Bell – 222 helicopter, these gears were used in the transmission system. Later, in the ART program, the company designed a 2 – stage HCR spur cylindrical planetary gear system. Although some problems such as high temperature in the high – speed stage and insufficient bearing capacity in the low – speed stage were encountered during the design process, after adjusting the number of teeth and bearing size, the final product showed significant improvements. Compared with the original LCR spur cylindrical planetary gear system, the mass was reduced by about 3.6 kg, and the bending strength increased by 20%.

The XV – 15 tilt – rotor aircraft developed by Bell Helicopter also utilized HCR spur cylindrical gears in its 2 – stage planetary gear system. This design reduced the noise of the entire transmission system and enhanced its survival ability.

The American Boeing Company conducted research on HCR spur cylindrical gears and non – involute tooth profile spur cylindrical gears. By adjusting parameters such as the addendum coefficient, pressure angle, and profile shift coefficient, they obtained HCR spur cylindrical gears with a contact ratio greater than 2.1. They also proposed solutions to address the problems of and contact durability.

The McDonnell – Douglas Company (McDonnell – Douglas) participated in the main reduction planetary gear design of the ART program. They used two schemes: HCR spur cylindrical gear planetary gears and internal meshing gear planetary gears at the pitch point. The HCR spur cylindrical gear planetary gears had a contact ratio of approximately 2.22. Compared with LCR spur cylindrical gear planetary transmissions, although the transmission efficiency decreased slightly and the tooth surface contact temperature increased, the mass was reduced by about 5% (31 kg), the noise was reduced by about 9.5 dB, and the service life was extended by approximately 1 time.

The Sikorsky Aircraft Corporation conducted dynamic analysis of HCR spur cylindrical gears and performed dynamic profile modification on the tooth surface. The results showed that a quadratic curve could be used as the profile modification curve, and the optimal modification area was from 90% of the addendum to the tooth tip. After profile modification, the fatigue life of HCR spur cylindrical gears at a failure rate of 10% was twice that of LCR spur cylindrical gears, and the was slightly higher.

The French state – owned aerospace company developed the SA – 365N “Dauphin” helicopter. Its main reduction gear planetary transmission system used HCR spur cylindrical gears. The sun gear and planetary gear, as well as the planetary gear and fixed ring gear, had contact ratios of 2.17 and 2.18 respectively. Flight test results showed that HCR spur cylindrical gears could significantly improve the load – carrying capacity of the planetary gear system and reduce the noise and vibration of the transmission system.

The Italian Agusta Company upgraded the input – stage gears of the A109 helicopter’s main reducer using HCR spur cylindrical gears. The improved helicopter, the AW109, showed a 10% increase in transmission power, a 20% reduction in gear tooth width, an 8% reduction in mass, and a 9 – dB reduction in the average meshing frequency noise measured on the test bench.

4.2 Applications in Domestic Helicopters

In China, research on HCR spur cylindrical gear transmission technology began in the 1980s. The introduction of the production patent for the French SA365N1 “Dauphin” II helicopter, with its HCR spur cylindrical gears in the main reducer, marked the initial step. However, it was not until the beginning of the 21st century that China truly started to conduct in – depth application research on HCR spur cylindrical gears.

Domestic universities such as Nanjing University of Aeronautics and Astronautics, Northwestern Polytechnical University, and the University of Jinan have carried out continuous research on the strength analysis, tooth contact analysis, and vibration characteristic analysis of HCR spur cylindrical gears, promoting the development of domestic theoretical research in this field. Some domestic research institutions have also conducted application research and initially obtained the transmission characteristics of HCR spur cylindrical gears. However, compared with foreign countries, the application of HCR spur cylindrical gears in China’s aviation transmission systems is still limited.

5. Technical Challenges Faced by HCR Spur Cylindrical Gears in China’s Aviation Field

5.1 Lack of Fatigue Strength Calculation Standards

Currently, there is a lack of publicly available fatigue strength calculation standards and software for HCR spur cylindrical gears in China. The American Gear Manufacturers Association (AGMA) gear calculation standard clearly states that it is not applicable to the precise design of spur cylindrical gears with a face contact ratio greater than 2. The ISO gear calculation standard, although considering the case of a contact ratio greater than 2, does not accurately calculate the load distribution among multiple pairs of meshing teeth and only provides simple corrections. As a result, it is difficult to accurately calculate the strength of HCR spur cylindrical gears. Current research in China mainly focuses on the calculation and analysis of tooth root bending stress, and the verification tests for bending stress measurement are often carried out under non – operating conditions. Further research is needed on contact strength, 胶合强度,and full – scale aviation transmission test pieces under actual working conditions to provide guidance for the engineering application of HCR spur cylindrical gears in lightweight and high – power aviation power transmission systems.

5.2 Deficiencies in Tooth Profile Modification Methods

The design of HCR spur cylindrical gears, which involves using a smaller pressure angle and a larger addendum coefficient, makes the tooth tip more prone to a large sliding rate, increasing the risk . To reduce this risk, tooth profile modification is necessary. However, the current research on tooth profile modification methods for HCR spur cylindrical gears in China is still in the stage of learning from LCR spur cylindrical gears. Although some results have been achieved, the effectiveness is limited. Some scholars consider profile modification from the perspective of vibration, but this approach has a relatively poor correlation with actual requirements.

5.3 Imperfect Tooth Surface Carburizing Process

HCR spur cylindrical gears usually have a large addendum coefficient, resulting in a small tooth tip thickness and a sharp tooth tip. To extend the service life of the gears, processes such as carburizing and nitriding are often used. However, thin – tooth – surface carburizing and nitriding can easily make the tooth tip brittle and cause tooth tip chipping. To prevent this, the tooth tips of HCR spur cylindrical gears are generally not carburized and are protected by copper plating before carburizing. This, in turn, reduces the hardness of the tooth tip, and the wear resistance of the gear becomes a prominent issue. Therefore, the heat treatment process for HCR spur cylindrical gears remains a challenge that requires in – depth research.

5.4 Inadequate Lubrication Design

The use of HCR spur cylindrical gears leads to an increase in the sliding speed between teeth due to the increased tooth height. This results in higher power losses, higher tooth surface temperatures, and reduced efficiency. Although HCR spur cylindrical gears have advantages in bending and contact strength, the risk is also increased. To dissipate the generated heat and reduce the probability ,more stringent lubrication requirements are needed. However, the current lubrication design for HCR spur cylindrical gears in China is still insufficient.

6. Solutions and Future Prospects

6.1 Establishing Strength Calculation Standards

China should invest in research to establish its own fatigue strength calculation standards for HCR spur cylindrical gears. This can be achieved through in – depth theoretical research, combined with a large number of experiments. By considering the unique characteristics of HCR spur cylindrical gears, such as the influence of parameters like the addendum coefficient, pressure angle, and profile shift coefficient on strength, a more accurate and reliable calculation method can be developed.

6.2 Developing Advanced Tooth Profile Modification Methods

To improve the performance of HCR spur cylindrical gears, it is necessary to develop advanced tooth profile modification methods. This can be achieved by studying the meshing characteristics and failure mechanisms of HCR spur cylindrical gears. By taking into account factors such as load distribution, sliding rate, and contact stress, more effective profile modification methods can be designed to reduce the risk and improve the overall performance of the gears.

6.3 Optimizing Heat Treatment and Lubrication Processes

For the heat treatment process, research should focus on developing new methods to ensure the hardness and toughness of the tooth tip without causing brittleness. This could involve exploring new heat treatment parameters or alternative surface treatment methods. In terms of lubrication design, new lubricants and lubrication systems should be developed to meet the high – temperature and high – load requirements of HCR spur cylindrical gears.

6.4 Future Prospects

As technology continues to advance, HCR spur cylindrical gears are expected to play an even more important role in the future of helicopter transmission systems. With the continuous improvement of design theory, manufacturing processes, and material properties, HCR spur cylindrical gears will become more efficient, reliable, and durable. They will not only contribute to the improvement of helicopter performance but also open up new possibilities for the development of aviation technology.

7. Conclusion

High contact ratio spur cylindrical gears represent a significant advancement in helicopter transmission technology. Their unique design and performance characteristics offer numerous advantages, including increased load – carrying capacity, improved transmission stability, and enhanced safety. However, in China, there are still challenges to overcome in terms of theoretical research, design standards, and manufacturing processes. By addressing these challenges through continuous research and innovation, China can catch up with international advanced levels and fully utilize the potential of HCR spur cylindrical gears in the aviation field. This will not only improve the performance of domestic helicopters but also contribute to the development of the global aviation industry.