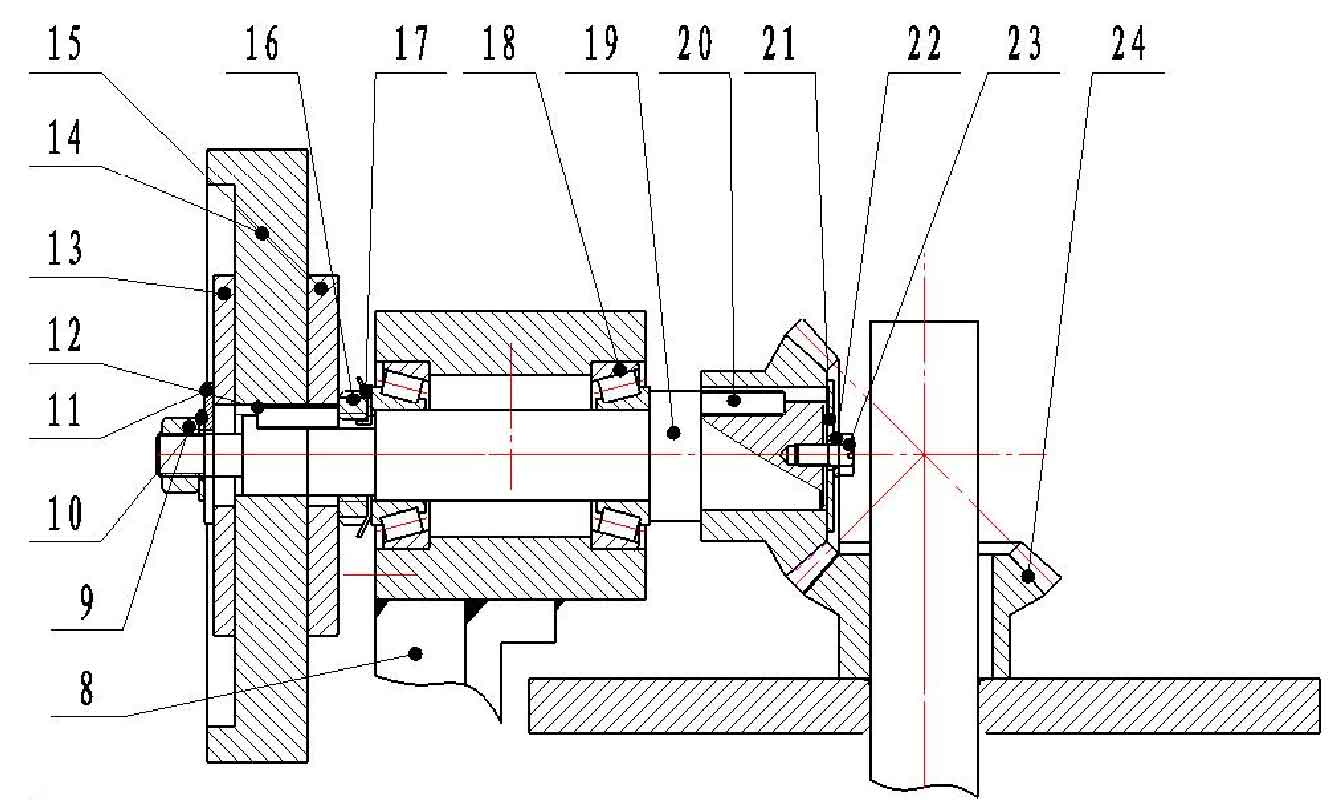

Before hobbing helical gear, first, prepare the combined fixture and clamp it correctly according to the relative position of each part. Secondly, install the tool correctly. Thirdly, adjust the split change gear and differential change gear used in hobbing, adjust the relevant parameters used in hobbing, and prepare for hobbing. After the adjustment of Hobbing machine, As shown in Figure 1.

When installing hob spindle and hob, pay attention to the following points:

(1) When installing the hob spindle, the flat square stressed side on the step must be close to the square hole of the main shaft, and then the hob spindle can be tensioned with a pull rod and matched with the taper hole of the main shaft.

(2) The accuracy of the processed helical gear is directly related to the correct installation of the hob. When installing the hob, ensure that the key parts of some parts are clean. For example, the end face of washer for hob spindle, hob hole and end face, spindle taper hole and hob spindle, etc.

(3) In order to ensure the symmetry of the tooth profile of the processed helical gear, the center of the helical gear blank shall be aligned. After the blank is accurately clamped in the fixture, the hob shall be aligned to make the symmetrical center line of one tooth groove of the hob coincide with the center line of the helical gear blank.

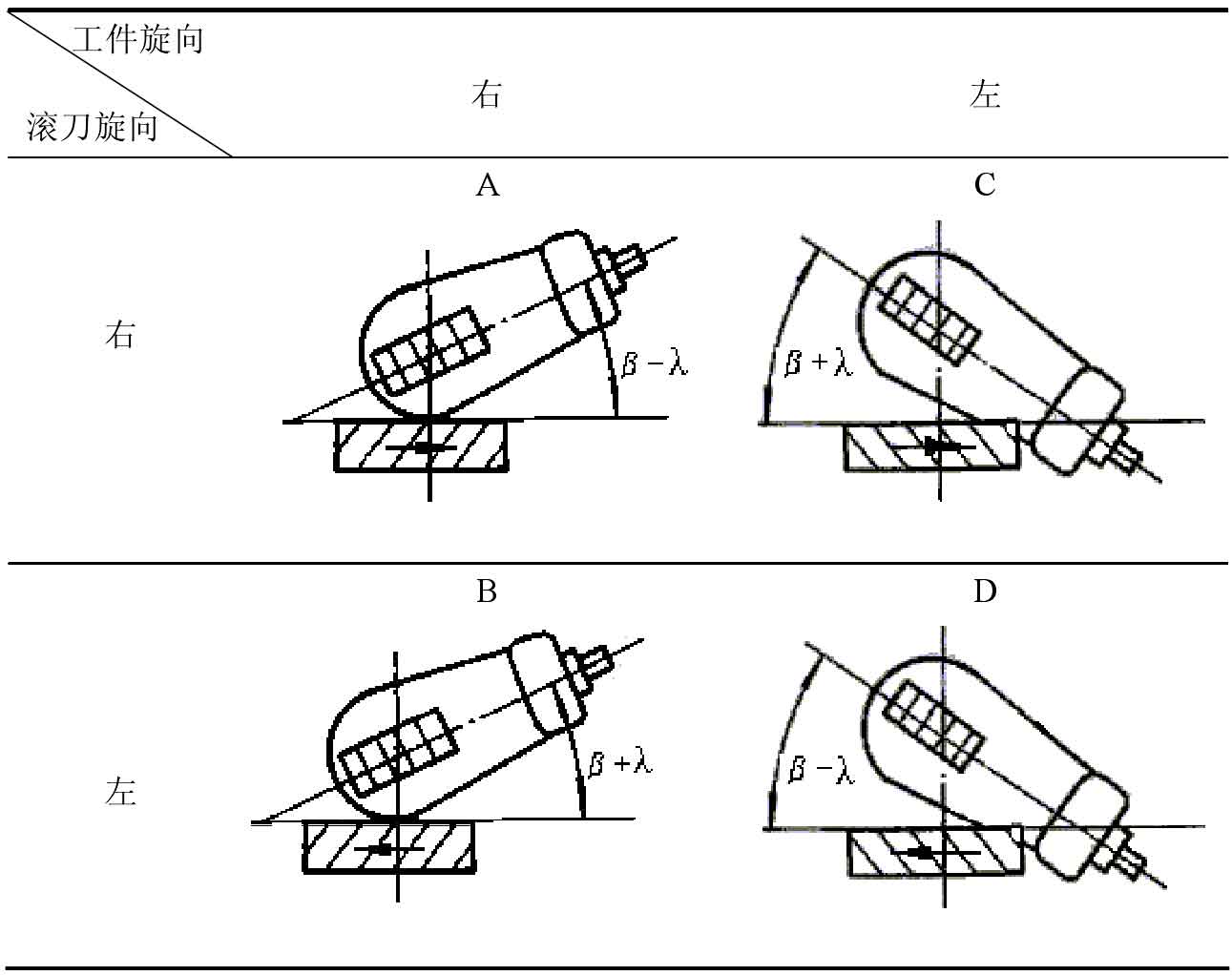

(4) When hobbing involute spur gear, the installation angle of hob is equal to the spiral rise angle of hob( λ). When hobbing involute helical cylindrical gear, the installation angle of hob( ω) It is related to four parameters, namely, the spiral direction of the hob and the spiral rise angle of the hob, the spiral direction of the processed helical gear and the spiral angle of the processed helical gear( β ) The size of the. When the spiral direction of the hob is consistent with that of the helical gear to be machined, the installation angle of the hob is equal to the difference between the two (i.e ω=β-λ); When the spiral direction of the hob is opposite to that of the gear to be machined, the installation angle of the hob is equal to the sum of the two (i.e ω=β+λ).

(5) After the installation angle of the hob is adjusted, micro feed (only if there is a cut mark on the gear blank) for trial cutting, and observe the rolling cutting of the workpiece. The purpose of trial cutting is to verify whether the hob is installed correctly.

The installation method of hob for hobbing helical gear is the same as that for hobbing helical cylindrical gear. The left-hand hob is used for hobbing the right-hand helical gear. Spiral angle of hob γ= 2 ° 29 ‘, helical angle of helical gear β= 10 °, so the installation angle of hob ω=β+γ= 10°+2°29′=12°29′。 The correct installation method of hob shall be installed according to figure 2B. This processing adopts reverse milling, as shown in Figure 3.