Among the various methods of gearbox condition monitoring and fault diagnosis, vibration diagnosis method is widely used because of its strong applicability, good effect, simple and intuitive test and signal processing. As an information carrier for predicting gearbox fault, vibration signal has excellent properties. This chapter studies and analyzes the gearbox vibration mechanism and the conventional analysis methods of gearbox vibration diagnosis.

Ideal gear refers to the gear with no error in manufacturing and installation and uniform tooth surface load. When the ideal gear rotates, there are both sliding and rolling on the tooth surface. The sliding friction will change the direction at the node and form pitch line impact. In addition, when each pair of teeth enter or disengage from meshing, the load and deformation on the teeth suddenly increase or decrease, forming meshing impact. The dynamic load composed of pitch line impact and meshing impact excites the meshing vibration of gear. Meshing vibration is an inherent dynamic characteristic in gear transmission, which has nothing to do with whether the gear has defects or not.

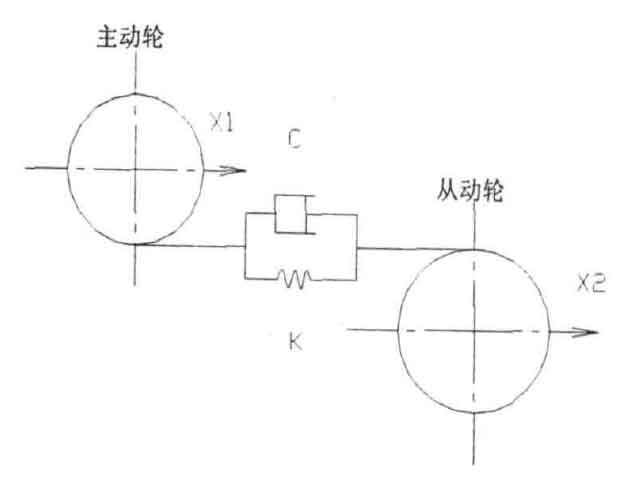

According to the research, when the ideal gear is meshed, the meshed tooth pair vibrates along the tangent direction of the linear speed direction of the gear transmission, and the dynamic model of the vibration can be simplified to the form shown in the figure.

The dynamic equation is:

Where:

X is the relative displacement of the gear in the tangential direction X = x2-x1;

C is gear meshing damping;

M is the converted mass of gear, M = M1 m2 / (M1 + m2);

K (T) is gear meshing stiffness;

E1 (T) is the average deformation of the gear after loading;

Because the meshing stiffness changes with the change of gears involved in meshing, the meshing stiffness changes periodically. The periodic change of meshing stiffness causes the periodic change of gear meshing vibration.