1. Setting of working environment parameters of gearbox

In order to obtain the influence of different design parameters of the gearbox on the total power more accurately, it is necessary to preset the working environment parameters of the gearbox on the premise of meeting the actual situation.

| Parameter name | Motor power | Motor speed | Kinematic viscosity | Dynamic viscosity | Friction coefficient | Tooth height multiple |

| Symbol/Unit | P/ kW | n /r·min^-1 | ν /cSt | μ /cP | f | k |

| Value | 10 | 10 000 | 60 | 0.1 | 0.06 | 0.8 |

The specific values are shown in Table 1.

2. Setting of gearbox design parameters

Taking the single-stage gear box as an example, for the standard involute helical cylindrical gear, the parameters in Table 2 have little effect on the total efficiency of the gear box. Therefore, these parameters are set at fixed values during the analysis of this study. The setting results are shown in Table 2.

| Parameter name | Pressure angle | Normal addendum height coefficient | Coefficient of normal top clearance | Tooth width |

| Symbol/Unit | αn /( °) | h*an | cn* | B/mm |

| Value | 20 | 1 | 0.5 | 20 |

Since the parameters are the main influencing parameters of the total efficiency of the gearbox, the set value range is shown in Table 3.

| Parameter name | Number of driving gear teeth | Transmission ratio | Helix angle | Normal modulus |

| Symbol/Unit | z1 | i | β /( °) | Mn /mm |

| Fixed value | 30 | 3 | 20 | 2 |

| Variation range | 10 ~ 50 | 1 ~ 6 | 8 ~ 45 | 1 ~ 4 |

3. Analysis of the effect of gearbox design parameters on efficiency

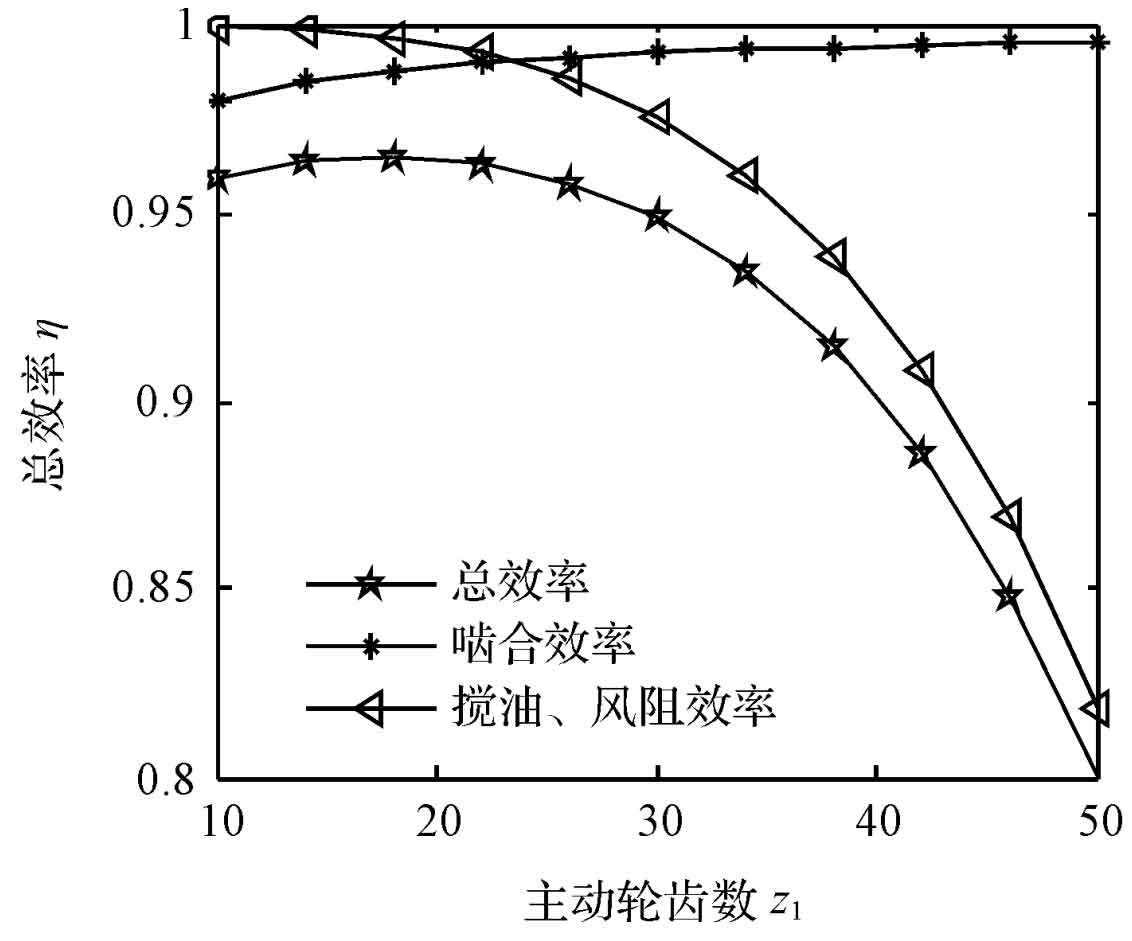

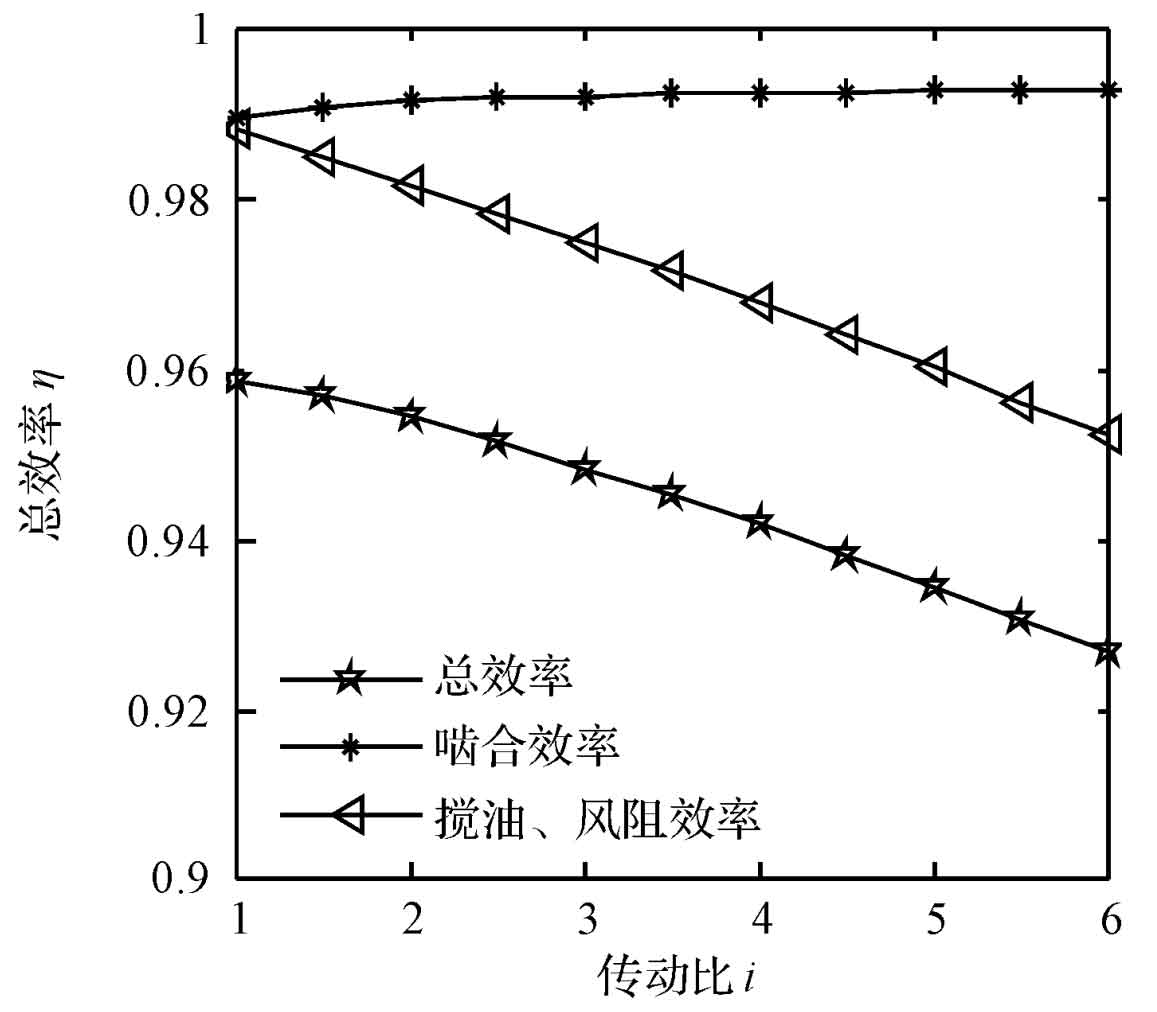

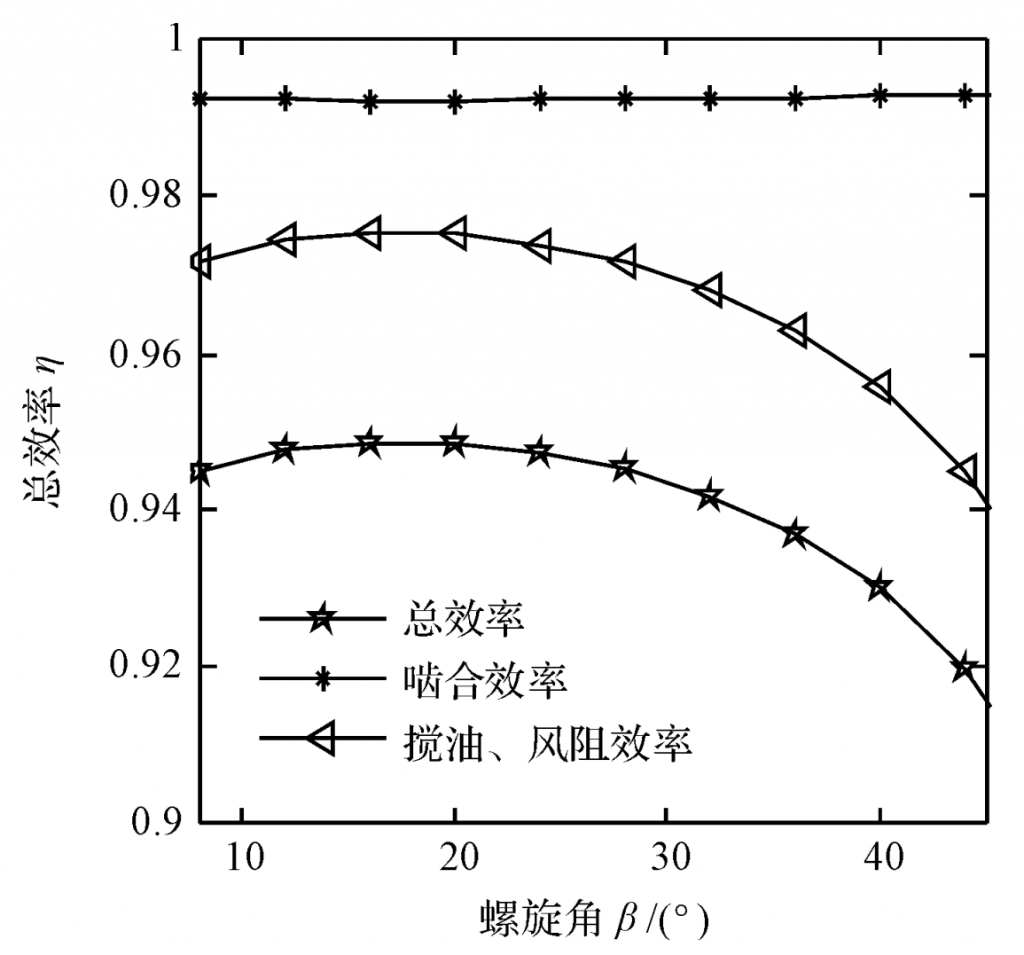

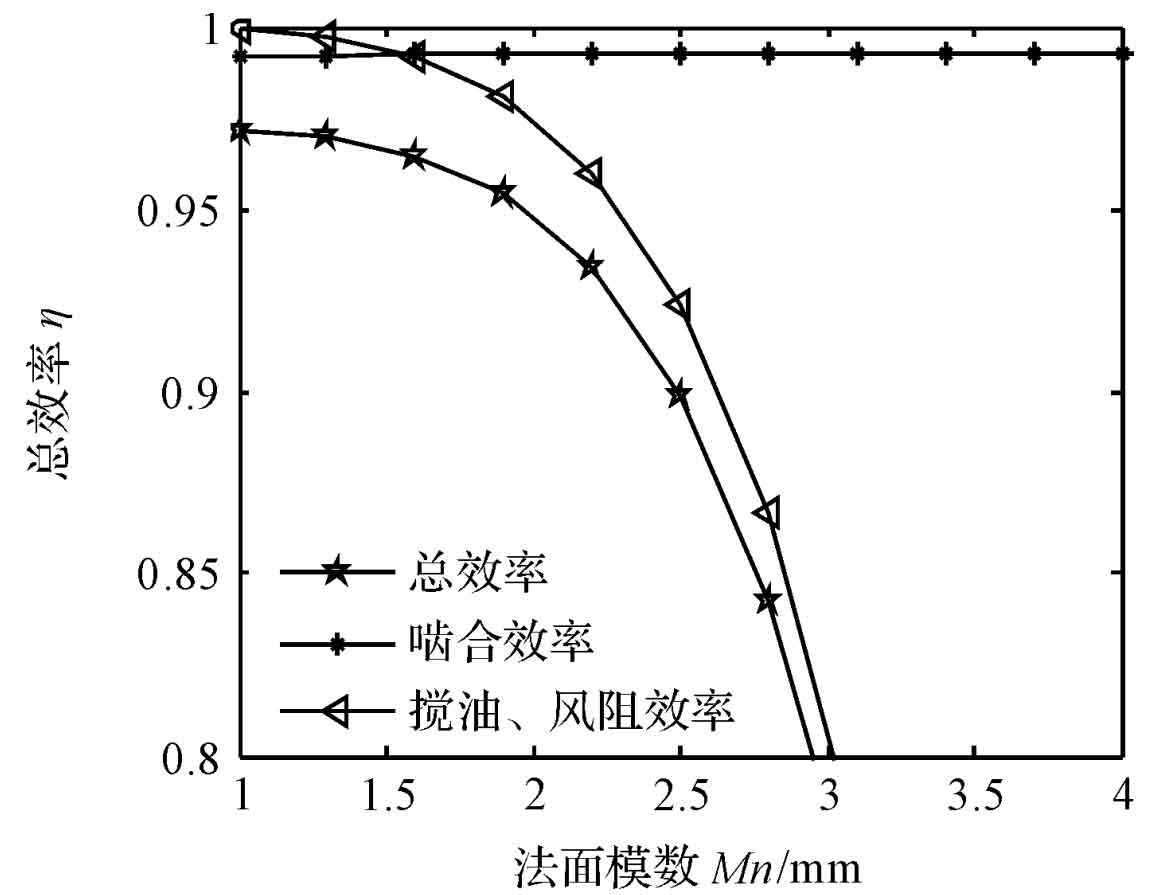

Using Matlab software, draw the influence curve of the main design parameters on the total efficiency of the gearbox under the condition parameter setting in Table 1, as shown in Figure 1-4.

The relationship between the driving gear and the total efficiency is shown in Figure 1. When z1 is within the range [10, 23], the total efficiency of the gearbox increases with the increase of z1, and reaches the maximum efficiency when z1=23. When z1 is within the range [23, 50], the total efficiency of the gearbox decreases with the increase of z1. In the interval [35, 50] of z1, the total efficiency of the gearbox decreases sharply with the increase of z1.

As shown in Figure 2, the total efficiency of the gearbox decreases with the increase of the transmission ratio within a given variation range.

As shown in Figure 3, when β In the interval [8, 20], the total efficiency is β Increase and increase when β In the interval [20, 45], the total efficiency of the gearbox follows β Increase and decrease.

As shown in Figure 4, in the given variation range, the total efficiency of the gearbox decreases with the increase of the normal modulus. When Mn is 2, the curve has an inflection point. In the range [1, 2], the total efficiency decreases slowly, and in the range [2, 4], the total efficiency decreases rapidly.

To sum up, the main parameters affecting the total efficiency of the gearbox are the number of driving gear teeth and the normal modulus. The oil stirring and wind resistance efficiency are the main factors affecting the total efficiency, and the change trend of the total efficiency is basically consistent with that of the oil stirring and wind resistance efficiency.