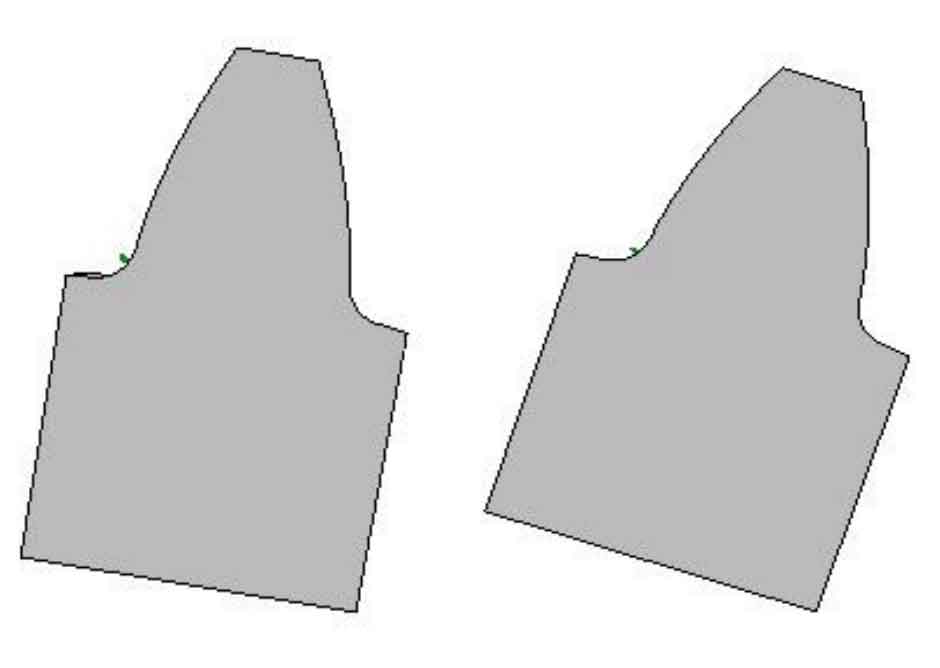

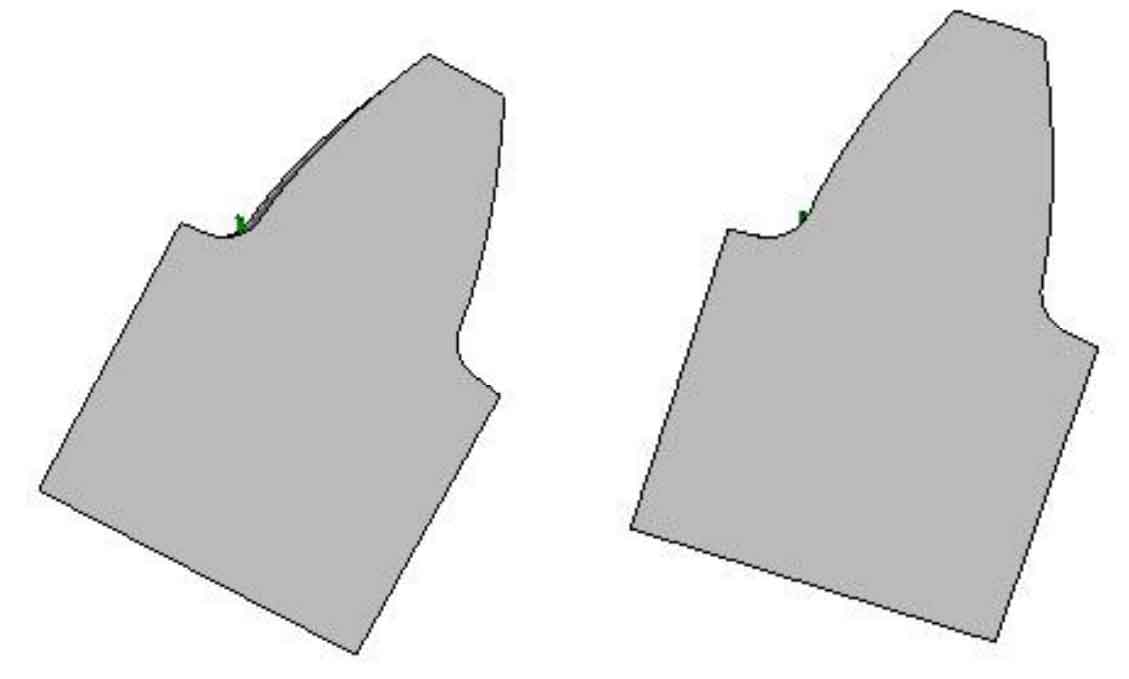

Previously, we used the joint simulation method of ANSYS and FRANC3D to carry out the static analysis of the root crack under three different distributed loads, the crack propagation simulation of spur gear and the calculation of its life. We still analyzed the influence of different positions of the initial crack on the crack propagation life according to the method. The prediction of crack propagation life of spur gear needs to be carried out on the basis of crack propagation. When predicting the influence of initial crack position on crack propagation life, the propagation step is still set as 7 and each propagation amount is 0.12. Only the influence of initial crack position on crack propagation life is analyzed, so the crack propagation process and final crack morphology results under different included angles will be omitted, and only the prediction results of crack propagation life are given.

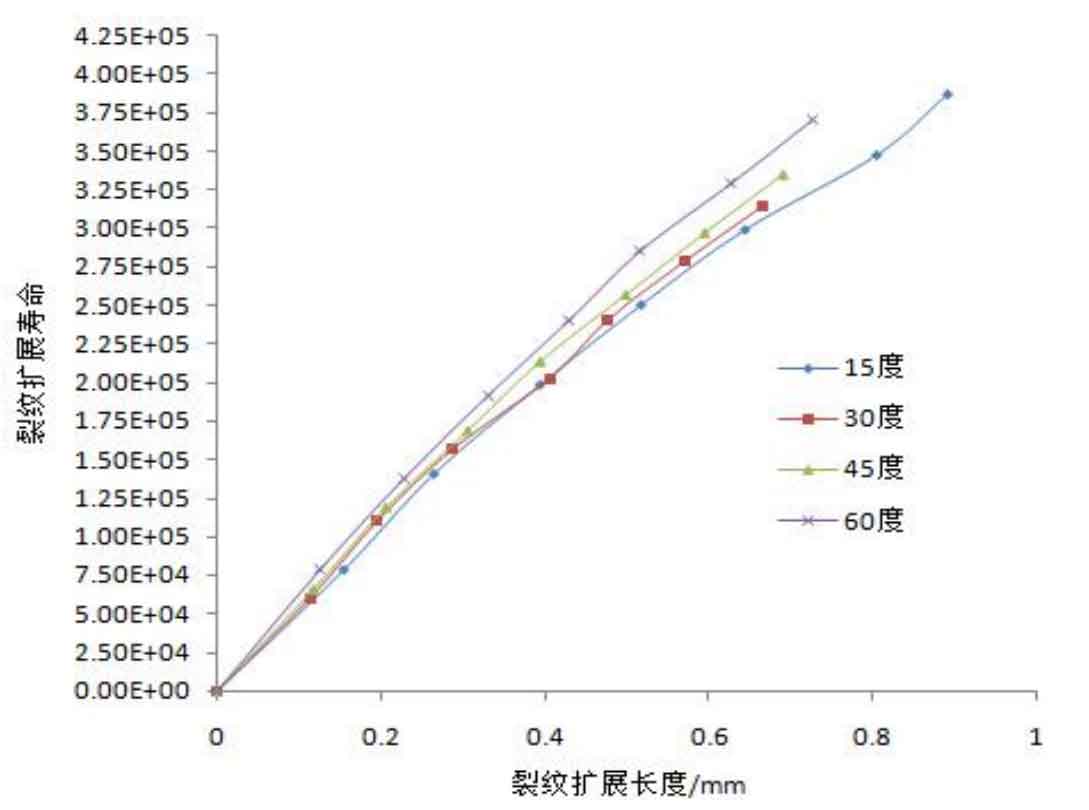

The life prediction results given by FRANC3D can be expressed by three different curves. The first is the life distribution on the path of the midpoint connecting the new crack front of spur gear after each step of propagation, the second is the crack propagation life curve drawn with the crack length on the surface of the crack body as the independent variable, and the last is the change curve given with the set number of propagation steps as the independent variable. From the data given by the software, although the set propagation amount of each step is 0.12, the actual propagation amount of each step is not 0.12 because there is a certain difference in the size of the stress intensity factor distributed at the crack front before and after propagation, and the propagation amount of spur gear along each node on the crack front is also different in the same step of propagation. In order to intuitively and clearly compare the changes of the fatigue life curve of spur gear when the plane where the initial crack is located has different included angles from XZ one side, the life curves of the four included angles are integrated into the same coordinate system, as shown in Figure 1.

It can be seen from the above figure that with the increase of the included angle, the longer the service life for the same number of steps. Therefore, it is concluded that the included angle between the initial crack plane of semi elliptical plate and XZ plane will affect the crack propagation life, and the greater the included angle, the longer the crack propagation life of spur gear. In the analysis of dynamic stress intensity factor, although Kii increases with the increase of included angle, its value is very small compared with KI, so it has little effect on the crack propagation life; The crack propagation of spur gear is mainly mode I, so the crack fatigue life is mainly determined by ki.

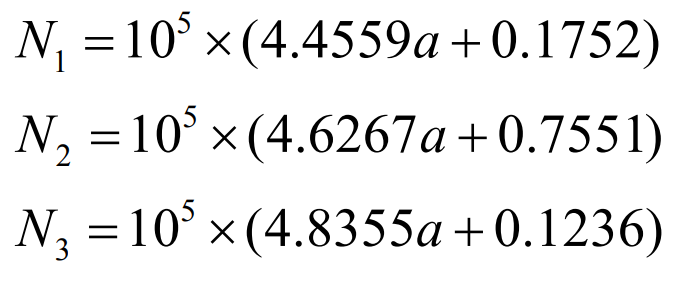

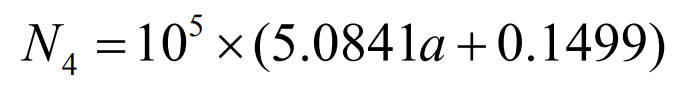

Figure 1 shows the change curve of crack propagation life of spur gear under different initial crack positions by means of scatter plot. This section will quantitatively give the change law of crack propagation life with crack propagation length (depth direction). It can be seen from the formula that the integral result of crack propagation life of spur gear is the primary function of crack propagation length. Therefore, the data of crack propagation life in Figure 1 can be fitted by MATLAB. It is obtained that under different initial crack positions, the relationship between crack propagation life and crack propagation length is as follows:

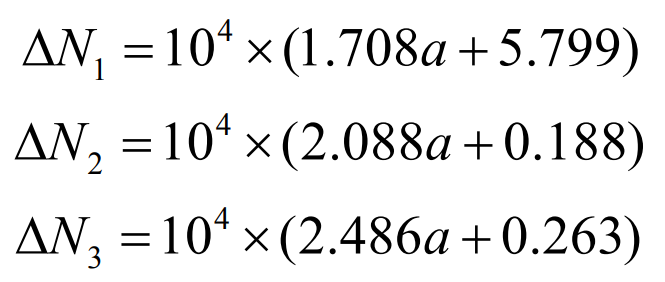

The above four formulas are the crack propagation life functions at four different positions of the initial crack of spur gear in Figure 2; Where a is the crack propagation length.

The included angles between the initial crack position of spur gear and XZ plane are 15 °, 30 °, 45 ° and 60 ° respectively. The increment between the included angles is 15 degrees. Now, through the crack propagation life function obtained by fitting, the increment of life of spur gear with the same crack propagation length under different initial cracks is analyzed.

Subtract from the formula to get the following result:

It can be seen from the formula that the crack propagation life of spur gears increases with the increase of the angle between the initial crack plane and XZ plane, and the increment of crack propagation life between adjacent angles also increases.