The selection of large diameter gear hobbing hob has the following advantages:

(1) Under the condition of maintaining the same blade back length, more slots can be used to improve the tooth profile accuracy of gear hobbing, and a larger axial tool walking amount can be adopted;

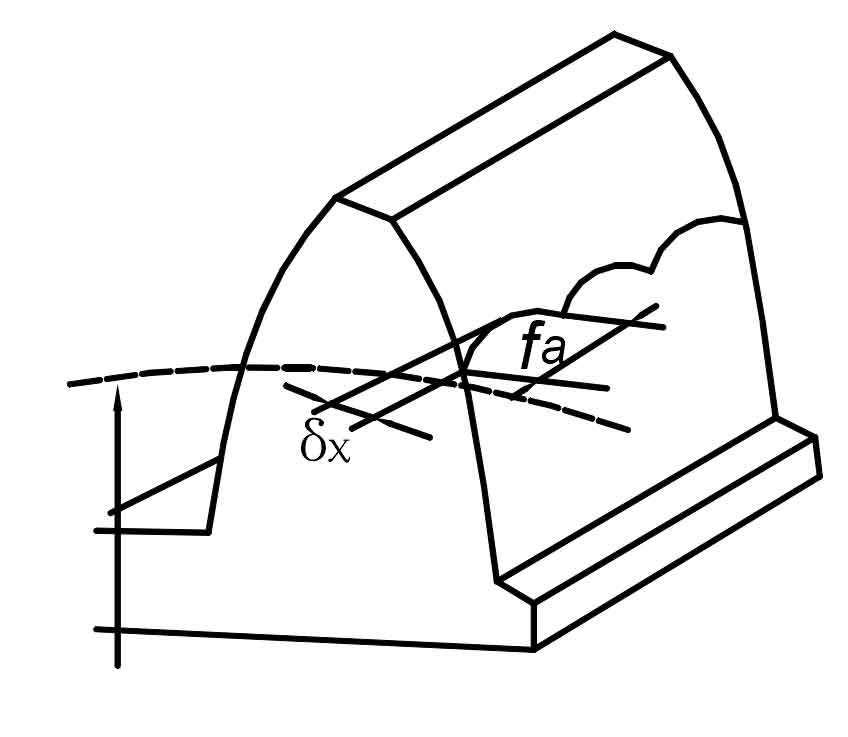

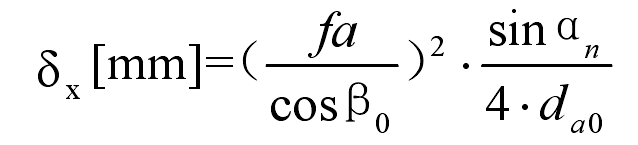

(2) Under the condition of adopting the same axial cutting amount, the cutting ripple height formed by large-diameter gear hobbing hob is less than that formed by small-diameter gear hobbing hob, as shown in the figure.

Where:

δ X [mm] – feed depth;

Fa [mm / R] – axial feed;

β 0 – helix angle;

α N — normal pressure angle;

Da0 [mm] – outer circle diameter of gear hobbing hob.

It can be seen from the formula that under the same cutting amount, the smaller the diameter of the top circle of the gear hobbing hob, the greater the depth of the cutting ripple. Therefore, on the premise of controlling the height of the cutting waviness, the larger the axial cutting amount can be selected by selecting the gear hobbing hob with larger diameter. For example, with the same axial cutting amount of 2mm / R, the cutting waviness caused by gear hobbing hob with diameter of 100mm is 0.0145mm, while that caused by gear hobbing hob with diameter of 80mm is 0.0182mm.