The number of hobs Z0 has an important influence on the machining time In some cases, the use of gear hobbing multi head hob plays a significant role in reducing machining hours The following items shall be considered when selecting the number of heads of gear hobbing hob:

(1) There should be no common divisor other than 1 between the number of teeth of the gear and the number of heads of the gear hobbing hob, so as to disperse the adjacent pitch error caused by the indexing error of the tool and the radial runout error of the tool installation;

(2) There should be no common divisor other than 1 between the number of heads of gear hobbing hob and the number of grooves of hob;

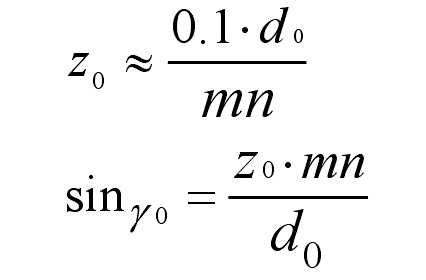

(3) The maximum number of heads that can be used in the application of gear hobbing straight groove hob shall control the spiral rise of gear hobbing hob not more than 6 degrees; If the spiral rising angle of gear hobbing hob is greater than 7.5 degrees, the tooth surface quality on the side where the cutter tooth wedge angle is obtuse angle will be reduced. For example, empirical formula:

According to the formula, with the increase of the number of gear hobbing hobs, the cutting load of the cutter teeth increases, so the tool walking amount adopted should be reduced accordingly.

| Number of gear hobbing hob heads | Decrease percentage of tool travel | Relative tool travel |

| 1 | 0 | 1mm |

| 2 | 20% | 0.63mm |

| 3 | 45% | 0.61mm |

| 4 | 58% | 0.59mm |

| 5 | 65% | 0.57mm |

| 6 | 70% | 0.55mm |

Gear hobbing multi head hob is not suitable for large axial tool walking in machine tools and tools. Under the condition of high-speed cutting, the use of gear hobbing multi head hob is a way to improve efficiency, but the use of gear hobbing multi head hob will increase the pitch error.