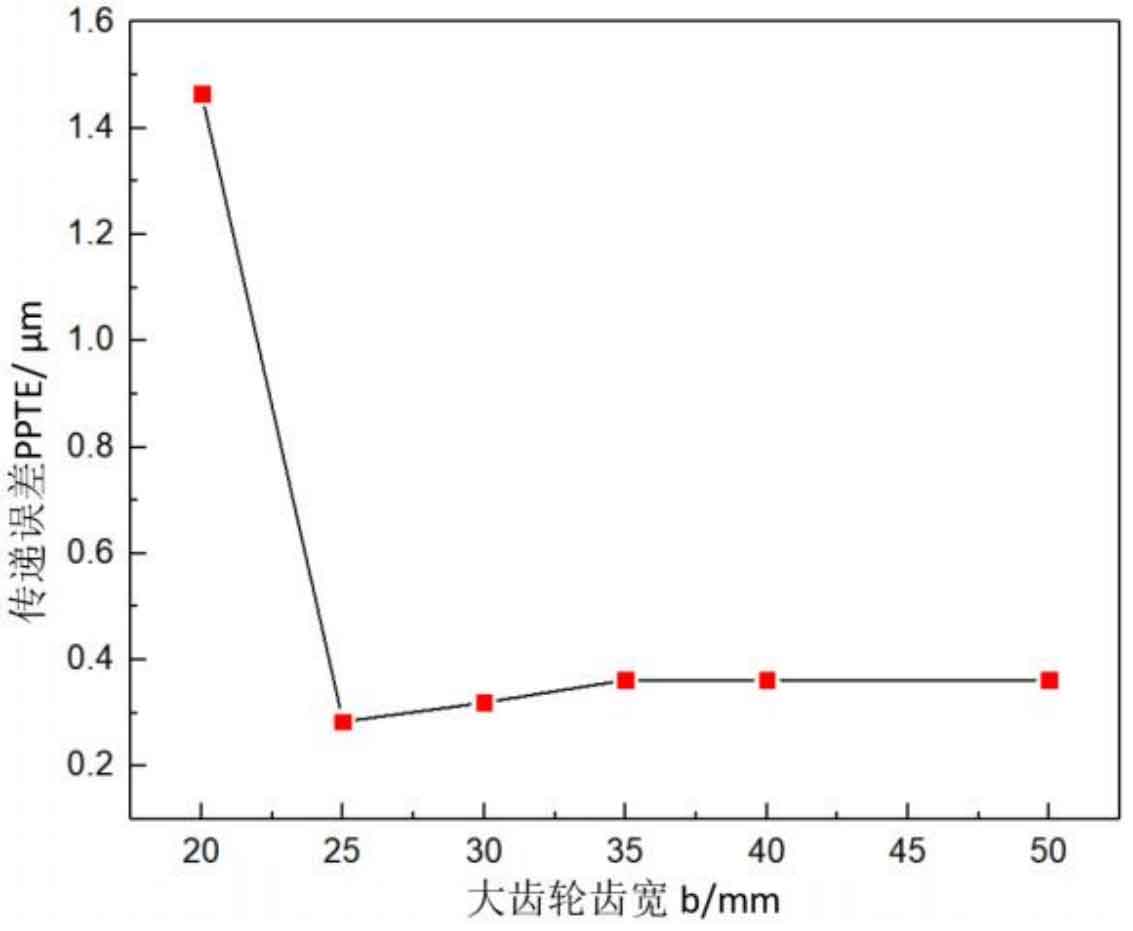

(1) Influence of gear width on transmission error of helical gear

Figure 1 shows the curve of the relationship between the tooth width of the big gear and the transmission error of the helical gear pair. It can be seen that in the range of 20mm~50mm, with the increase of the tooth width of the big gear, the transmission error decreases significantly first, then increases slightly, and finally tends to remain unchanged when the tooth width reaches 35mm. When the tooth width of the big gear is 25mm, the transmission error of the helical gear pair is the lowest, 0.284 μ m。

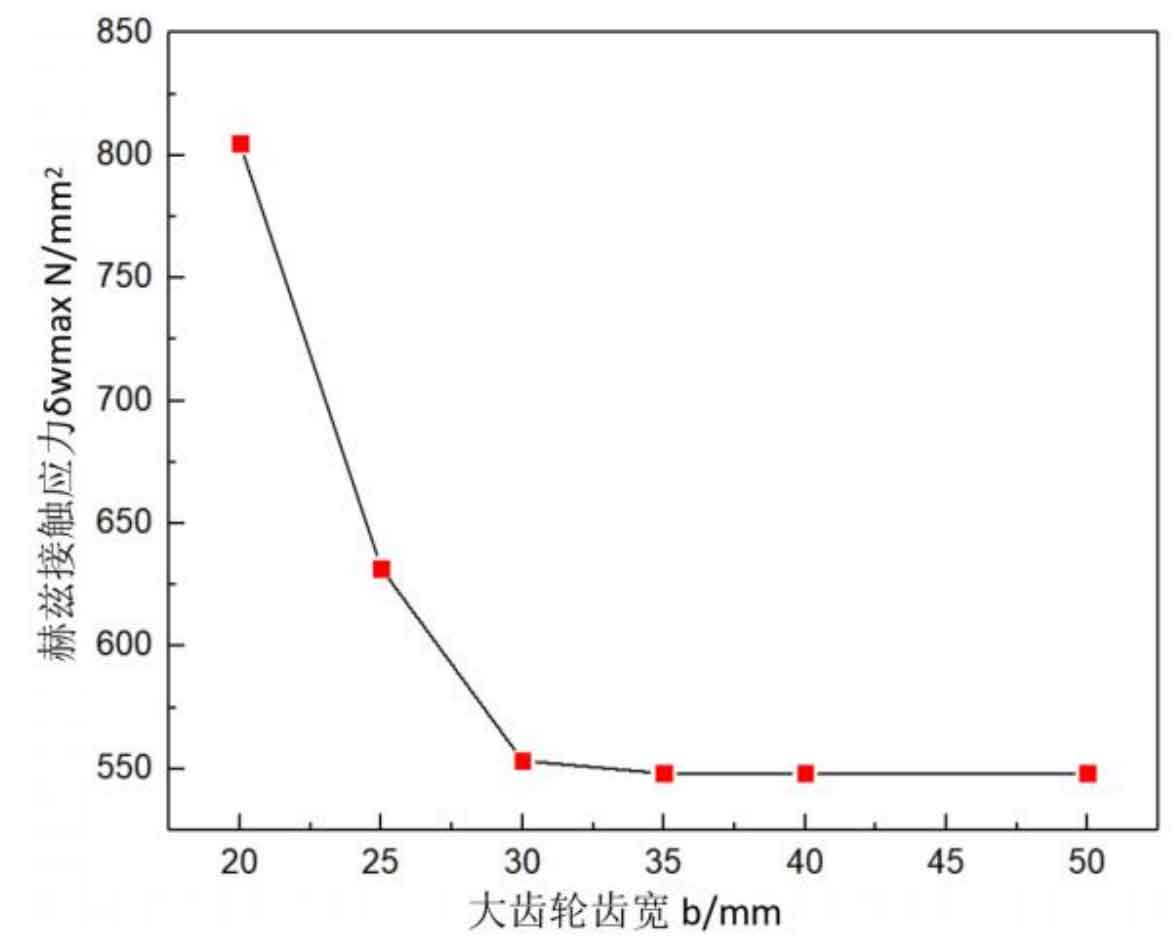

(2) Influence of gear width on hertz contact stress of helical gears

Figure 2 shows the Hertz contact stress relationship curve between the gear tooth width and the helical gear pair. Within the variation range of the tooth width, the Hertz contact stress first decreases with the increase of the tooth width, but when the tooth width increases to 35mm, it stabilizes at the lowest point 548.094N/mm2.

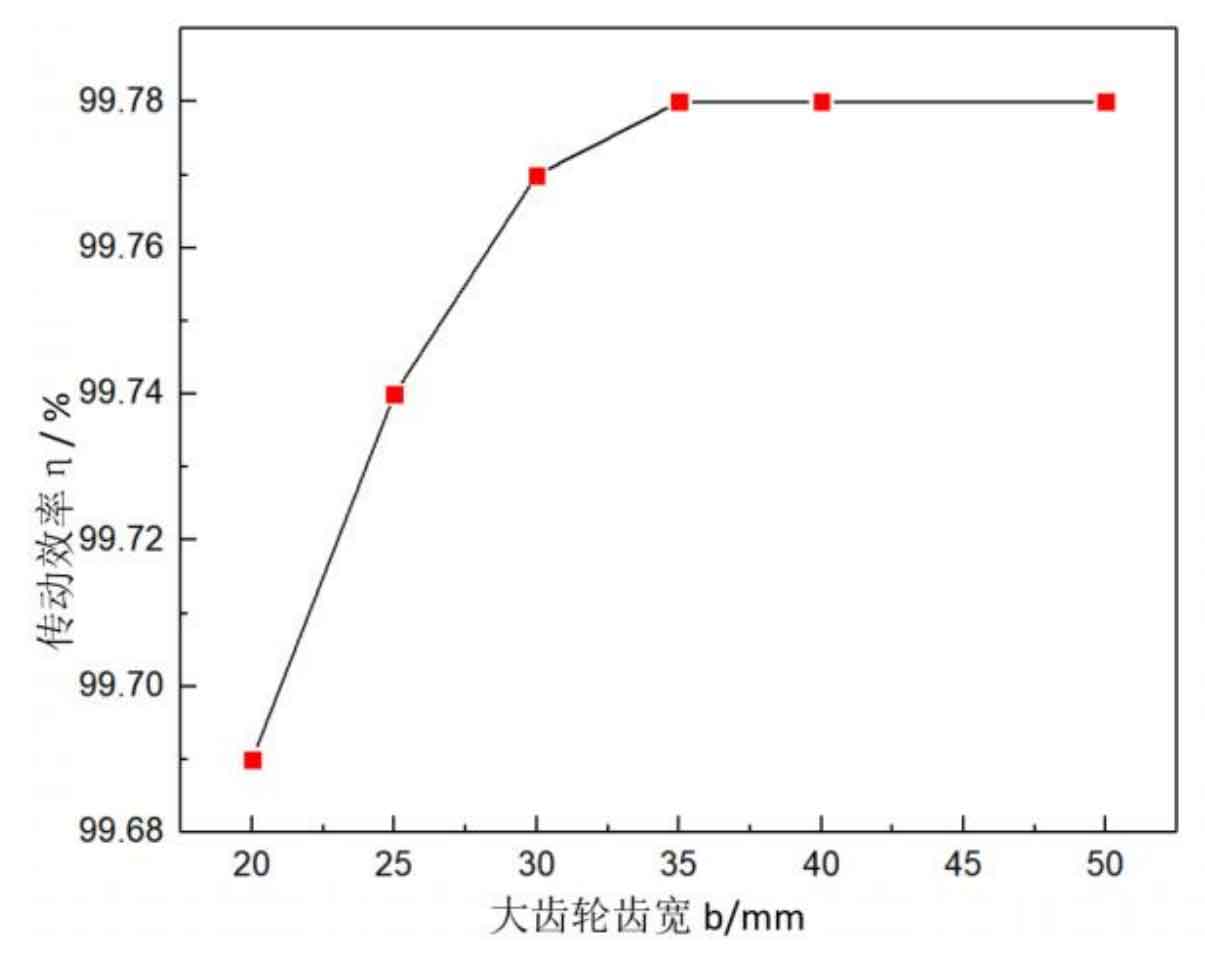

(3) The Influence of Big Gear Width on Helical Gear Transmission Efficiency

Figure 3 shows the relationship curve between the tooth width of large gear and the transmission efficiency of helical gear. It can be seen that with the increase of the tooth width, the transmission efficiency first continues to increase, but when the tooth width exceeds 35mm, the transmission efficiency is stable at 99.78%.

To sum up, the transmission efficiency and Hertz contact stress of the gear pair can be improved by properly increasing the tooth width of the large gear.