The variation law of grinding parameters on grinding force is studied, that is, the effects of grinding depth, grinding speed and spiral bevel gear speed on grinding force. The single factor test is designed by comprehensively considering the test conditions, and the specific parameters arranged are shown in table.

| Grinding conditions | Parameters |

| Grinding wheel diameter (mm) | 400 |

| Grinding wheel grain size | 46 |

| Grinding speed (M / s) | 15.2, 17.8, 20.3, 22.8, 25.3 |

| Grinding depth(μm) | 10, 30, 50, 70, 90 |

| Workpiece speed (mm / min) | 600, 1200, 1800, 2400, 3000 |

| Grinding mode | Single pass reverse grinding |

| Grinding width | 5 mm |

| Cooling mode | Dry grinding |

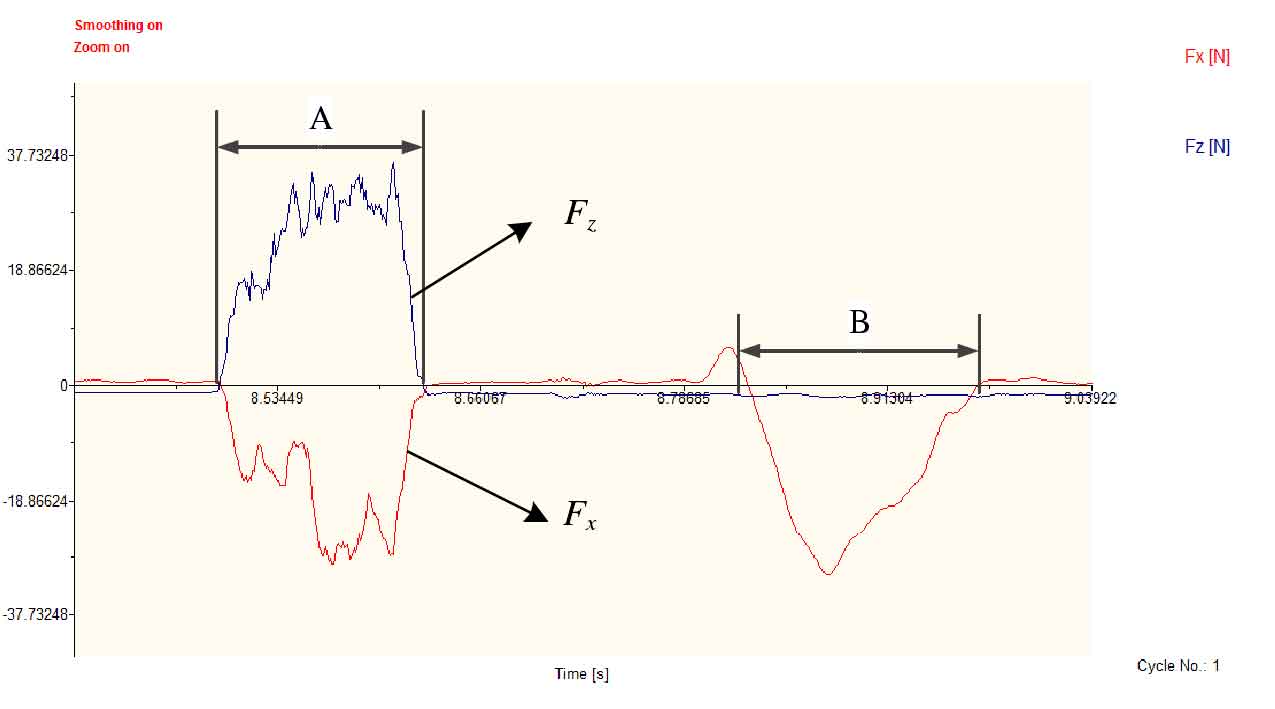

Before measuring the grinding force of spiral bevel gear, first compensate the zero drift of Kistler dynamometer, set the sampling frequency to 24000 Hz, and then set the appropriate sampling time. Then start the measurement before grinding to obtain the waveform of spiral bevel gear grinding force, select the corresponding channels of tangential force FX and normal force FZ, and filter the waveform. The waveform obtained after filtering is shown in the figure.

In the figure, the blue curve represents the normal grinding force and the red curve represents the tangential grinding force. The actual grinding force value of the spiral bevel gear is the average value of the net value-added generated in the signal. Since the zero point compensation processing has been carried out on the instrument before the measurement, the actual grinding value of the spiral bevel gear is the average value of the A-segment signal in the figure. In addition, the large tangential force generated in Section B is caused by the collision with the reversing stop during the reversing process of the workbench, so FX generates a large impact signal in the figure.