The selection of gear hobbing multi groove hob has the following advantages:

(1) Gear hob has many grooves and good tooth shape;

(2) Reduce the cutting load on the rake face, reduce tool wear, and increase the amount of tool travel;

(3) It can prolong the cutting time of one grinding, increase the number of cutting workpieces and reduce the number of tool changes;

(4) If the number of circumferential teeth of the gear hobbing hob is 20, the 20 cutter teeth can cut the tooth length of 100m at one time. If the gear hobbing hob has only 12 cutter teeth, the tooth length of 60m may be cut at one time. That is to say, the number of grooves of the gear hobbing hob is large, and the number of gears processed at each grinding can be increased.

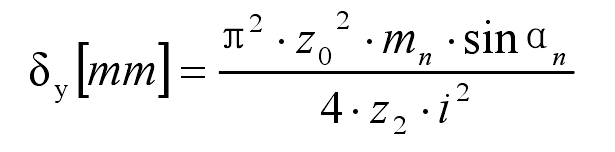

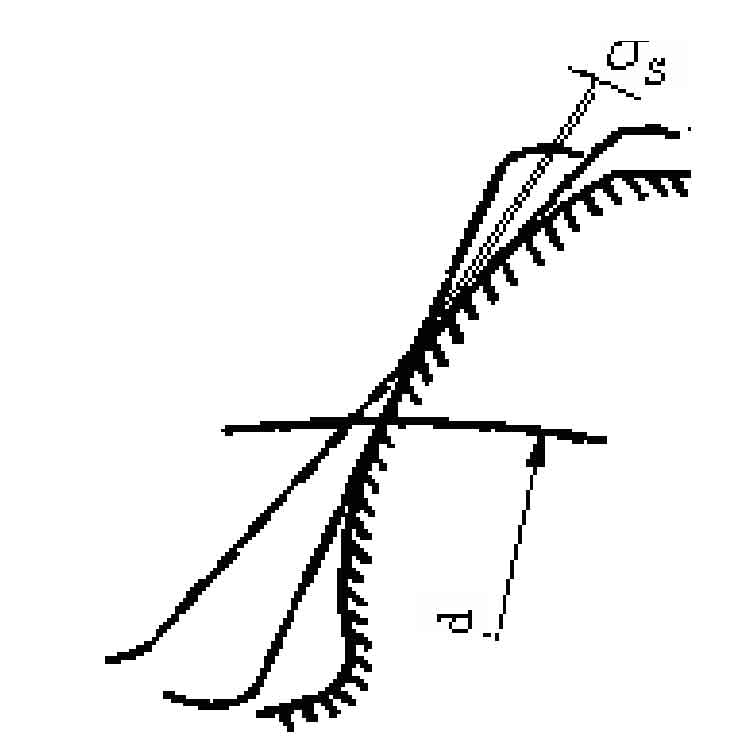

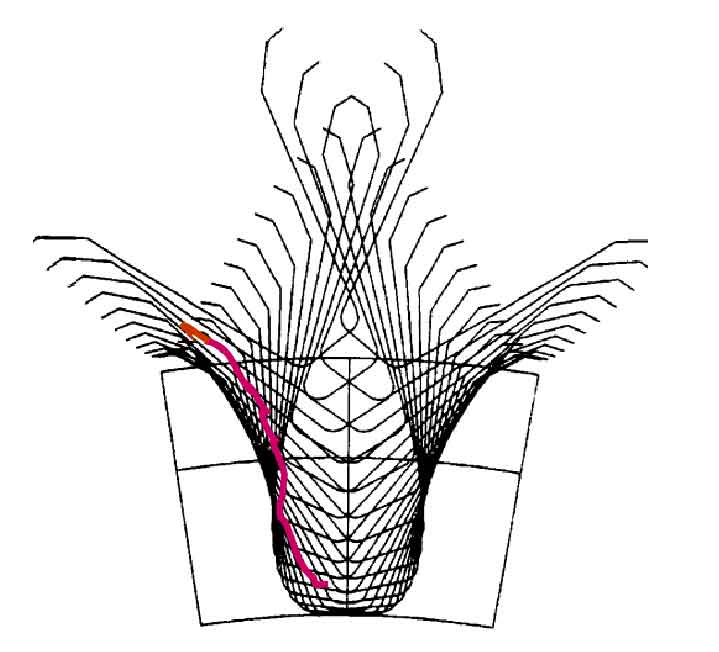

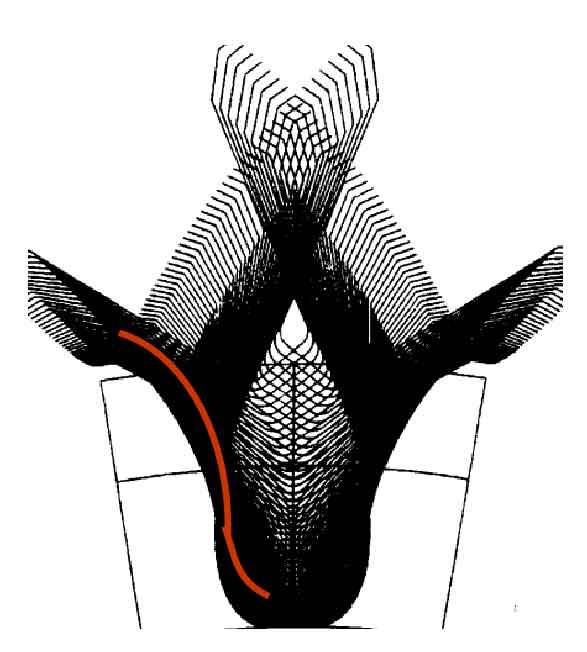

As shown in the figure, the envelope error of gear profile is:

Where:

δ Y [mm] – envelope deviation of gear hobbing tooth profile;

Z0 – number of heads of gear hobbing hob;

Z2 — number of teeth of gear;

I — number of grooves of gear hobbing hob.

After calculation, the theoretical envelope error of 12 groove gear hob is – 0.0015mm; The theoretical envelope error of 24 groove gear hob is – 0.0004mm.