The model is shown in the figure. The tooth thickness error of the tool in the axis direction will affect the machining accuracy of the machined gear, mainly in the tooth thickness of the gear.

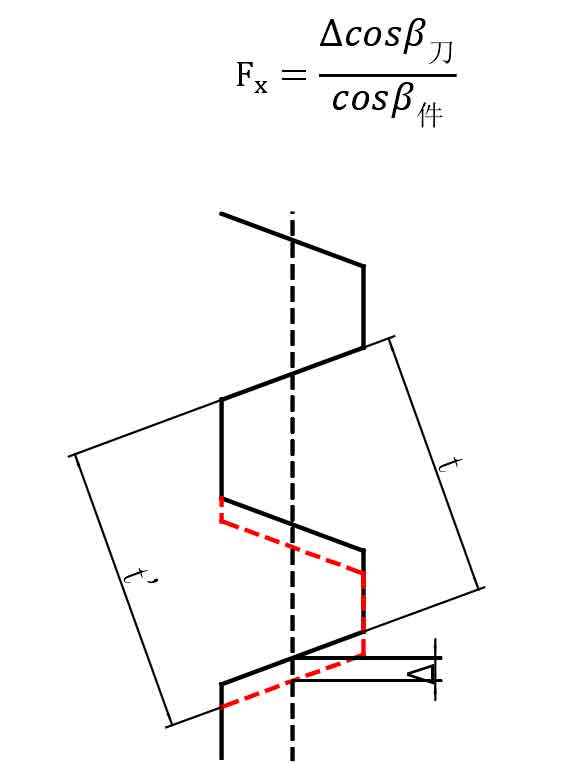

Under normal circumstances, the gear hobbing hob and the gear mesh on the pitch circle (gear indexing circle), so the tooth thickness error on the gear end face of the gear hobbing hob will be directly mapped to the gear. As shown in the figure, the gear hobbing hob has a tooth thickness error ∆, and the tooth thickness error of the gear is:

According to the GB / t6084-2001 standard of gear hob, the helix error of the inner cutting edge of gear hob in one turn is specified as the maximum axial error of the intersection of the cutting edge and the concentric cylindrical surface of the inner hole to the theoretical helix of gear hob within one week of gear hob.

Helix error will affect the tooth profile error of gear.

Assuming that the helix error is ∆, according to the above definition and meshing principle, the tooth profile error can be obtained: