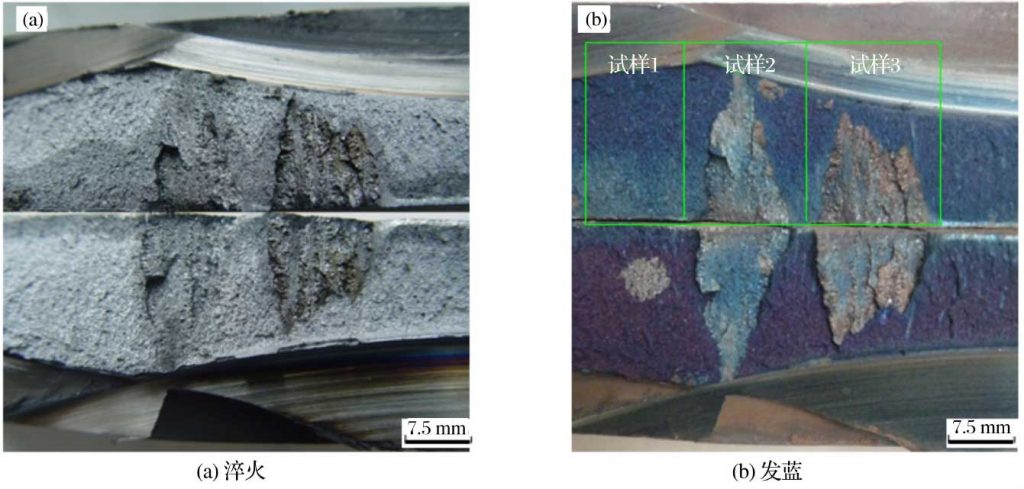

After quenching and bluing treatment, fracture inspection and Bluing test are conducted after longitudinal fracture of steel. Through observation, it is found that the normal fracture surface is relatively flat, which is a brittle fracture with fine grain (porcelain shape). The separation surface of internal crack is longitudinal strip and a small amount of crystal structure, and there is no friction trace on both sides. No macro defects such as non-metallic slag inclusion or inclusion were found after bluing treatment. The macro morphology of fracture is shown in Fig. 1.

Samples 1, 2 and 3 were cut by WEDM according to Fig. 1 (b), and the fracture morphology was observed by SEM. The fracture morphology of sample 1 at normal position is cleavage fracture morphology of river pattern, and sample 2 and 3 at defect position are relatively flat and similar to river pattern. No other defects are found in microscopic inspection except for tear marks of normal fracture surface. The fracture morphology is shown in Fig. 2.