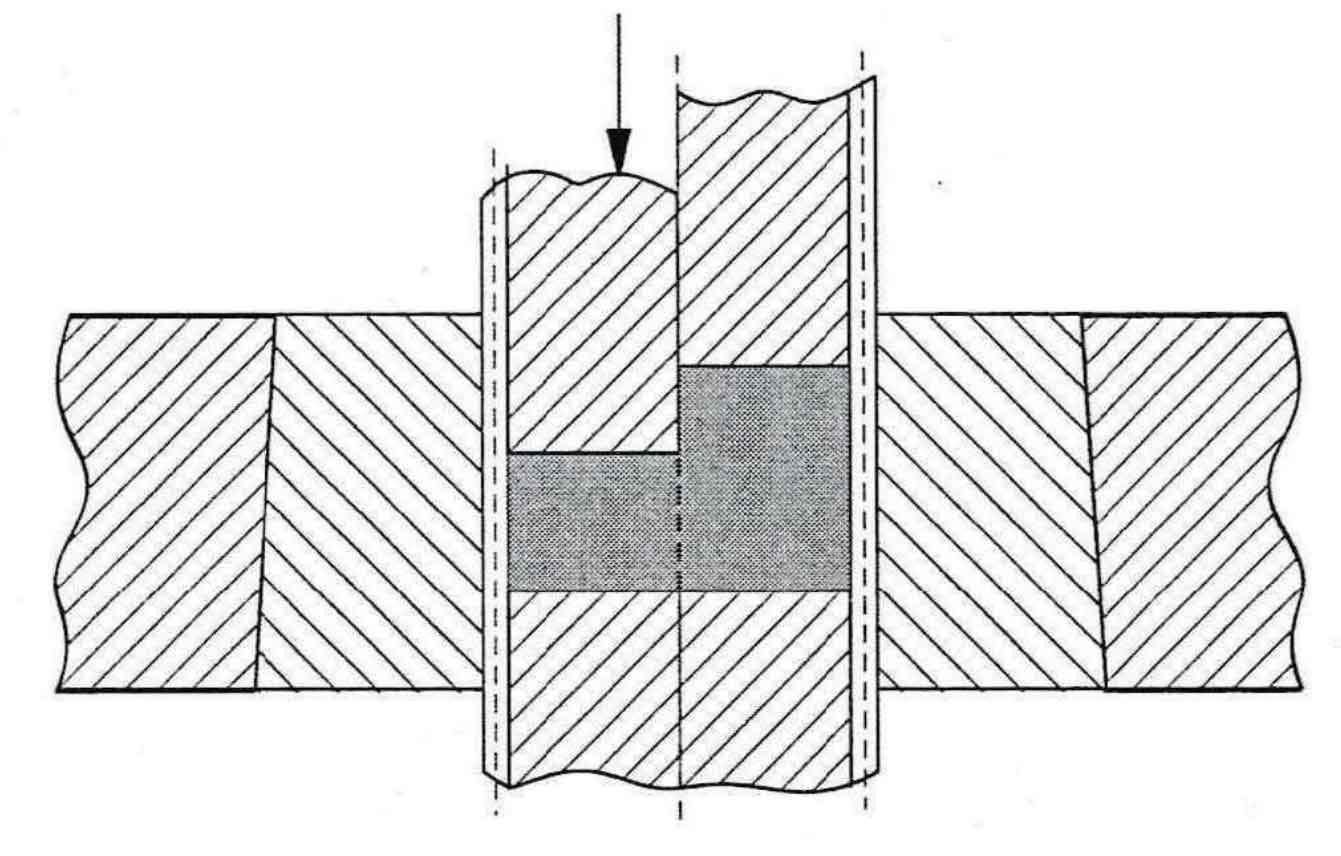

Isothermal forging technology originated in the United States in the 1960s. It refers to the forging and forming of blank under relatively stable temperature. Isothermal forging is suitable for the precision forming of difficult to deform materials. Perer et al analyzed the die design and mechanical properties of AA5083 ultrafine grained gear pretreated by equal channel angular extrusion and isothermal forging. Shan et al. Introduced in detail the equal wet forging technology of LV alloy shell. In the 1960s, the forging process of cylindrical gear was affected by the low cost from the automotive industry, and achieved great development in the 1970s. In the 1980s, the gear forging technology tended to be perfect, the accuracy and consistency reached a high standard, and the industrialized production could reach a high level of automation. However, in the forging process of spur gear, the metal flows perpendicular to the force direction, so its forming is more difficult than that of bevel gear. The forging process of spur gear basically adopts closed pier extrusion, as shown in Figure 1. Because the deformation is in a closed environment and cold forming, the flow stress in the forming process is high. In the later stage of forming, the metal flow is greatly limited, the deformation resistance inside the cavity increases sharply, due to the limitation of insufficient equipment tonnage or die strength, Finally, some defects such as insufficient filling of local tooth profile are caused. Many experts and scholars at home and abroad have discussed and analyzed this problem, but they can not fully fill the tooth profile, especially the large module gear.

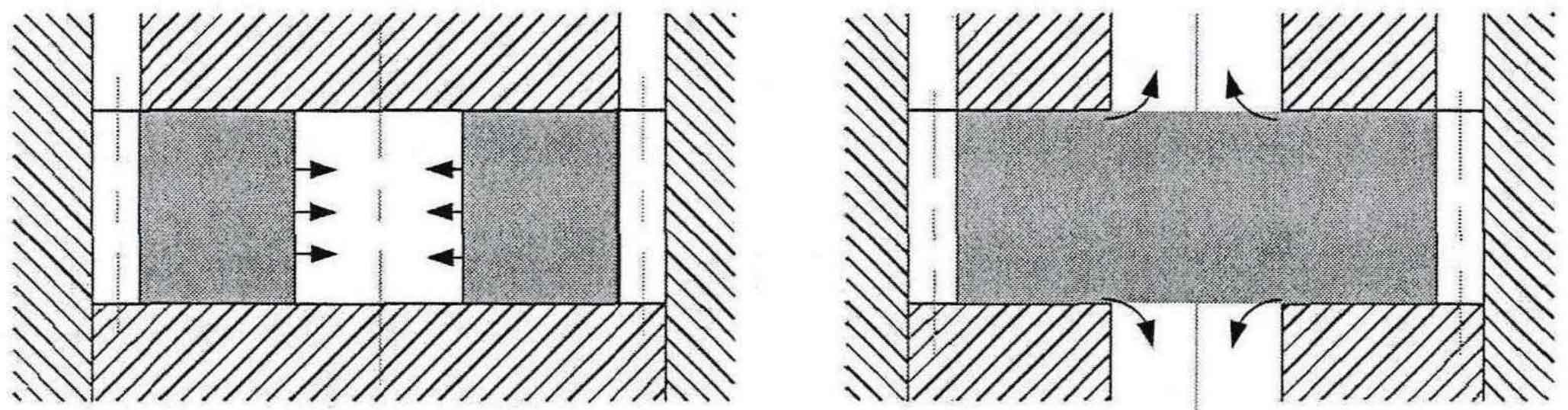

Aiming at the problem that the deformation resistance of gear forging is large and the tooth shape is not easy to be filled, scholars at home and abroad put forward a variety of process methods to reduce the deformation resistance and try to apply it to production practice. Japan and western developed countries are in a leading position in the world in precision forging technology, including gear precision forging technology. In the mid-1980s, ohga and Kondo of Japan first proposed the application of shunting principle in the cold precision forging of spur gear. The forming principle is shown in Figure 2. A hole cavity is set at the non working surface of the gear to ensure that the materials can be shunted to this point during the forging process and prevent the sharp increase of deformation resistance in the later stage of forging, Thus, the forming force is reduced, and further analysis is made to obtain the optimal shaft diameter when axial shunting is adopted, and the forging pressure decreases with the increase of shunting hole diameter when hole shunting is adopted. The forming quality of forgings with axial shunting and hole shunting is compared, and the conclusion that axial shunting is thicker than hole shunting is obtained. Luo et al. Adopted the forming process of closed pre forging split final forging for spiral bevel gear, and compared it with transmission closed die forging through numerical simulation. The results show that this process is more conducive to reducing the forming load and improving the filling capacity of tooth profile.