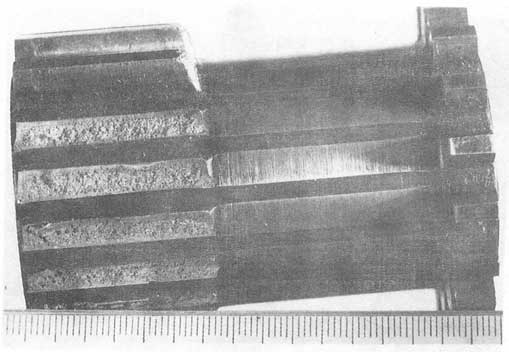

The lathe with invalid gear is made in Japan, the surface of the gear is carburized, and it has been used for more than 30 years. During the use process, the phenomenon of broken gear occurs. The field inspection of the accident found that the cutting feed is too large when processing the workpiece. The fracture morphology is shown in Figure 5.

The gear fracture belongs to the fast fracture under the action of high stress. The fracture features of the tooth root edge are dimple and intergranular fracture, which is related to the carbide precipitated along the crystal and the high carbon concentration at the grain boundary in the carburized layer. The results of microstructure and material examination are normal. After the inspection and analysis of the damaged gear, it can be concluded that all the broken teeth are new cracks formed in this accident. The results of field inspection show that there are quite a lot of deep cutting tool marks on the workpiece, which shows that the gear is mainly broken due to stress concentration due to improper manufacturing process.

Macroscopic appearance of gear fracture. There are 7 broken teeth in the whole gear, and the crack source is all generated in the root of the tooth. The two sides of the fracture edge are flat, the middle is rough, and the small facet characteristics can be observed. The macroscopic morphology of the first six teeth is basically the same, and the plastic deformation characteristics of the seventh tooth can be observed, and its morphology is shear lip shape.