The drum bears the function of cutting coal. The load on the drum has an important impact on the stress state, cutting energy consumption and component reliability of the shearer. The drum load is composed of the pick force participating in the cutting and the coal loading load of the spiral blade of the drum. These loads can be equivalent to the cutting resistance moment TZ, propulsion resistance FX, cutting resistance FY and lateral force FZ acting on the mass center of the drum, as shown in Figure 1. The positive direction of x-axis is the haulage direction of shearer, the positive direction of z-axis is perpendicular to the outward direction of coal wall, and the positive direction of y-axis is determined by X and Z according to the right-hand rule.

The size of drum load is determined by the shearer traction speed, drum speed, coal rock properties and drum structure parameters. In production practice, in order to improve the mining efficiency and ensure the safety of equipment, the cutting motor is generally kept running near the rated load by adjusting the traction speed. If the average value of cutting resistance torque is 0 Tz0, then the mean value of the three-dimensional cutting force can be estimated by the following empirical formula

Where, RD is the radius of the drum, κ x is the coefficient related to the wear degree of the pick, and the value range is [0.6,0.8], and κ Z is the coefficient related to the structure of the drum, and the value range is [0.2,0.3].

Due to the anisotropy and brittleness of coal, the load of drum fluctuates. When there are gangues or hard inclusions in the coal seam, the fluctuation degree of roller load increases. Considering the fluctuation characteristics of the roller load, the roller load is constructed by the static mean value and transient fluctuation value of the load

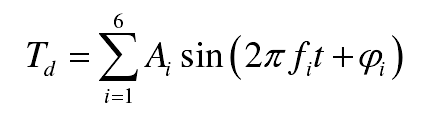

Where, R0 = [00tz0fx0fy0fz0] t is the mean value of the roller load; KD is the load fluctuation coefficient, which represents the ratio of the fluctuation amplitude of the cutting resistance torque to the rated value; TZR is the rated value of the cutting resistance torque, which is equal to the product of the rated torque of the cutting motor and the transmission ratio of the cutting transmission system; ˆ td = TD / max (TD) is the normalized load fluctuation curve, and the value range is [- 1,1], where

Where, F1 is the frequency caused by the rotation of the drum; F2 is the frequency caused by the number of blade heads; F3 is the frequency caused by the number of sections on each blade; F4 is the frequency caused by the number of picks on each section; F5 is the frequency caused by the circumferential angle of two adjacent picks on the blade; F6 is the frequency caused by the number of pick groups on the end plate; AI is the amplitude of the corresponding frequency component; and φ I is the initial frequency First phase. Equation (2.34) is from reference [6], and from the simulation experimental data published in the reference, the value of kdtzr / tz0 is about [0.1,0.2].