At the beginning of the new century, Ali needs large bevel gears with higher bending strength when transmitting power on domestic large reducers and other equipment. The processing technology of such large bevel gears is higher than that of ordinary automobile gears. A German company has put forward a gear processing method called HPG and AMK series machine tools, which are specially used to process gears with large module and small number of teeth, which are different from the requirements for small module and large number of teeth of automobile gears. They are called Klingenberg bevel gears in China.

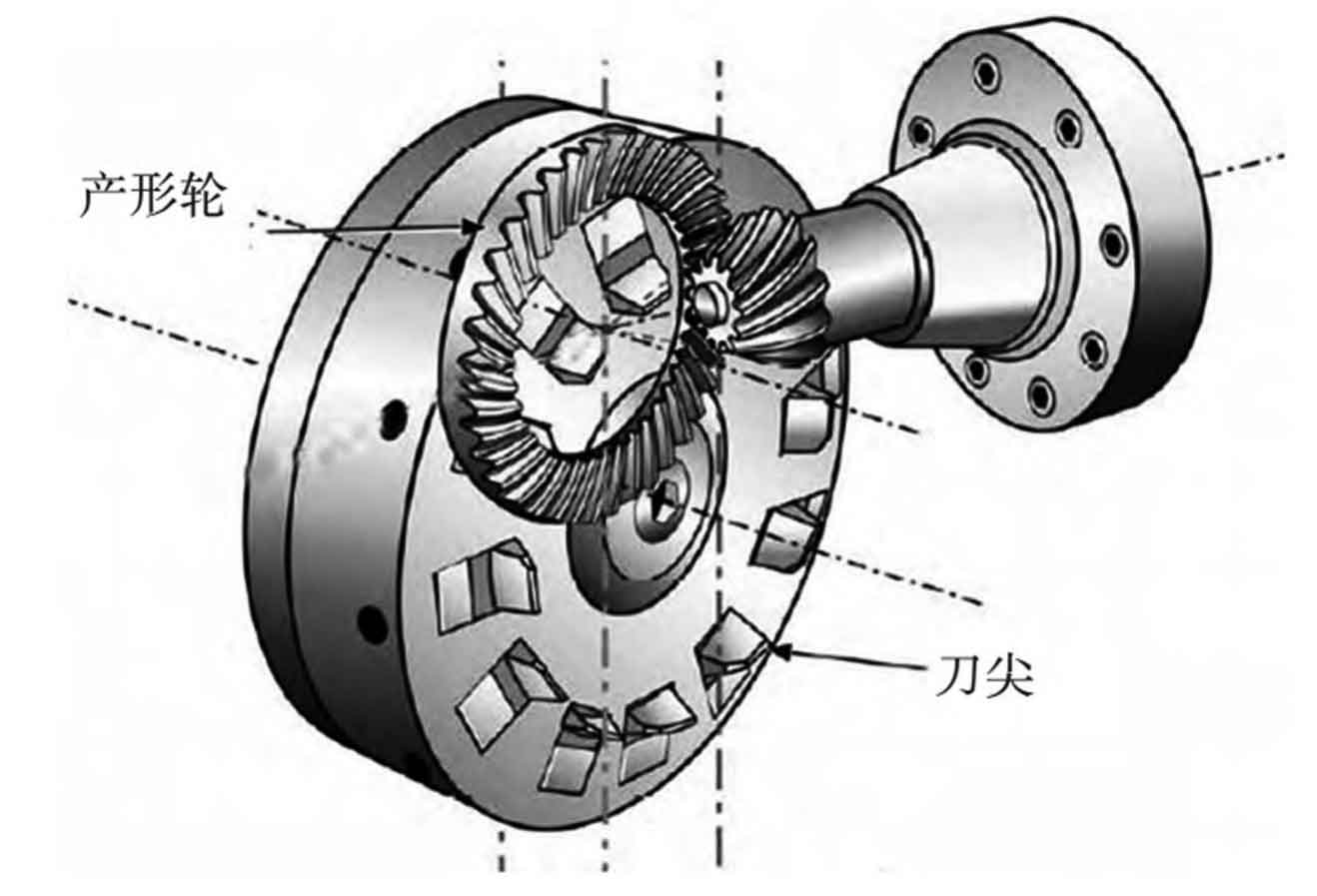

This machining method mainly uses cycloid contour teeth to process with a double-body cutter head with 5 sets of track teeth. After the processed tooth germ is heated, the CBN cutter head with negative rake angle is used for tooth scraping. This processing method can eliminate the problem of bevel gear precision reduction caused by heat treatment deformation, increase the residual compressive stress generated on the surface of bevel gear during heat treatment, and improve the bearing capacity of bevel gear. It is especially suitable for producing various bevel gears with small quantity and many types. At present, based on the cutting technology of cycloid bevel gears, China has used the five-cutter method to process the Klingberg bevel gears on the domestic CNC gear milling machine.

With the rapid development of China’s economic construction, the oil mining, metallurgical manufacturing and other industries have an increasing demand for large specifications and high-precision spiral bevel gears. To study the processing technology of large specifications and high-precision spiral bevel gears, it is necessary to break the foreign technological monopoly, narrow the gap between the domestic gear industry and the international gear manufacturing power, and focus on independent research and development of core key technologies, Continuously improve the machining accuracy and quality of large and high-precision spiral bevel gears.