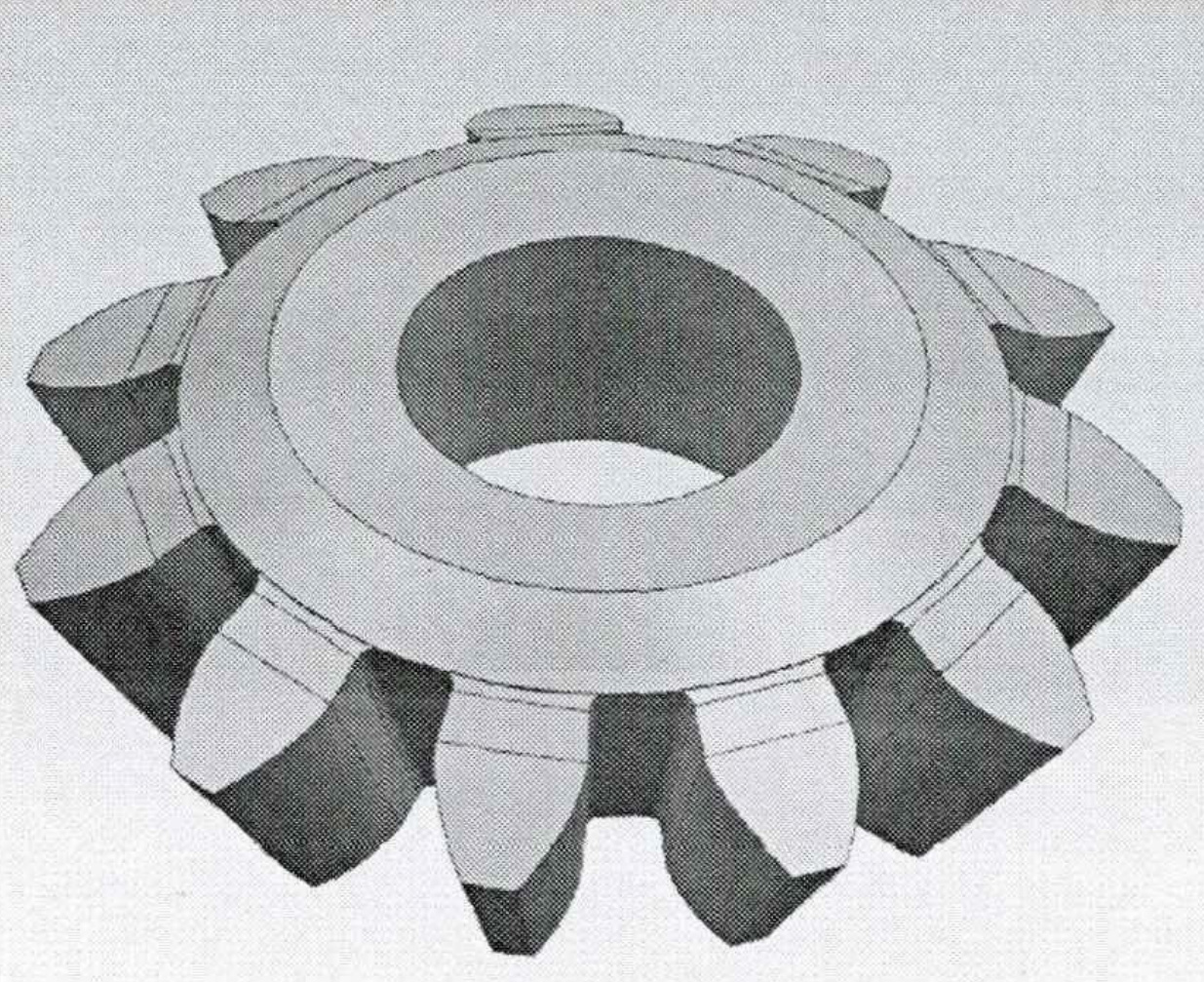

With the rapid development of the manufacturing industry and the continuous improvement of market demand, the demand and quality of spur gears are becoming higher and higher. Spur gears will be affected by various factors in the specific production process, resulting in defects on the surface of spur gears. The defects of spur gear surface affect the use of users, so how to effectively detect the defects of spur gear surface is worth studying.

At present, the detection of surface defects of spur gears is mainly carried out by manual means, which is simple and easy to operate. However, due to the existence of subjective factors, this method has great limitations, and this method requires high experience of workers. If such work is carried out for a long time, it may cause fatigue and lead to low detection efficiency. At present, there are two NDT methods, eddy current flaw detection and magnetic flux leakage detection. The eddy current flaw detection method has high accuracy, but requires manual participation, and the degree of automation is low; Magnetic flux leakage testing technology can not give a comprehensive evaluation of spur gear defects. Therefore, the above spur gear defect detection methods can not meet people’s needs for spur gear defect detection, and artificial intelligence spur gear defect detection algorithm is needed to improve the accuracy and efficiency of spur gear defect detection.

Under this background, the research of spur gear defect detection is carried out, and the spur gear defect detection based on improved K-means algorithm and improved particle swarm optimization algorithm is proposed, which meets certain practical needs, improves the production automation of spur gear products, and realizes the informatization of spur gear defect surface detection, improves the detection efficiency, and reduces the detection cost, which is of great significance for the spur gear production field.