In 1981, Litvin and Gutman first proposed to use the comprehensive analysis method to determine the machining parameters of “format” and “helixform” machine tools. Many subsequent hypoid gear studies are based on this document. In 1987, Litvin et al. Proposed a method of generating tooth surface geometry based on the conjugate surface principle for spiral bevel gears to simulate the tooth surface contact and meshing of gears, and described its calculation process in detail. In 1988, Litvin et al. Proposed a method to determine the parameters of machine tools for machining hypoid gears and spiral bevel gears by the tool inclination method. In 1989, Litvin et al. Used the preset parabola transmission error method to improve the linear transmission error caused by the installation deviation in gear meshing, which can reduce the meshing impact and meshing noise of gears and improve the meshing coincidence degree of gears. They described in detail the local synthesis method for calculating the parameters of gear processing tools, and compiled the corresponding calculation program. In 1994, Litvin published the first edition of the monograph on gear geometry and theoretical application, in which the author systematically summarized the previous research results in gear geometry calculation and optimization. After that, Litvin et al. Continuously improved the gear design and analysis methods proposed. For example, in 2002, Litvin et al. Proposed a comprehensive design method for spiral bevel gear tooth surface processing parameters, tooth surface contact stress analysis, and gear transmission error optimization. In 2005, based on the local synthesis method of spiral bevel gears, Litvin et al. Proposed a method for automatically calculating the meshing midpoint of the tooth surface for gear contact analysis and transmission error analysis (TCA). In 2006, litivin et al. Proposed a method to optimize gear processing parameters to improve gear contact, reduce gear meshing transmission error and reduce gear meshing noise. At the same time, many other scholars have studied the design and optimization of hypoid, such as gabiccini M., artoni a. simonv, etc. these studies mainly focus on the fields of gear geometric shape, gear dynamic performance, lubrication performance, stress analysis and measurement, gear machining deviation and coordinate measurement.

Spiral bevel gears have been invented and widely used for hundreds of years, but their processing methods and design methods have always been technically monopolized by a few companies in Europe and the United States. Although they understand their basic processing principles, their core technologies are not publicized. There are still a large number of scholars studying its design and processing in China. For example, in 2013, Kong Xianghan studied the modeling method of spiral bevel gear NC grinding tooth surface, established the grinding wheel model and theoretical tooth surface model by using numerical methods, established the spiral bevel gear grinding tooth surface simulation model according to the relative motion relationship and influencing parameters in gear grinding, and analyzed the generation law and influencing factors of tooth surface morphology. In 2013, Hong Zhaobin proposed a generation line tooth cutting method based on the generation principle of spherical involute tooth surface to process the tooth surface of spiral bevel gears. On this basis, the design and gear cutting of helical spiral bevel gear are deeply studied, and a new method of helical spiral bevel gear manufacturing technology is established. In 2016, Wei Bingyang and others proposed to use the surface synthesis method to optimize the processing parameters of spiral bevel gears, and use the ease off difference tooth surface of the conjugate tooth surface of large and small wheels to carry out meshing analysis. The optimization results achieved better control of the meshing performance of the tooth surface. In 2016, Tan Rulong and Xiang Dongyun proposed a new design method of double point contact equal angle spiral bevel gear pair based on the meshing principle of conjugate curve by studying the spatial conjugate curve, and established a solid model. They also studied the tooth surface contact strength theory and test technology of the new gear pair.

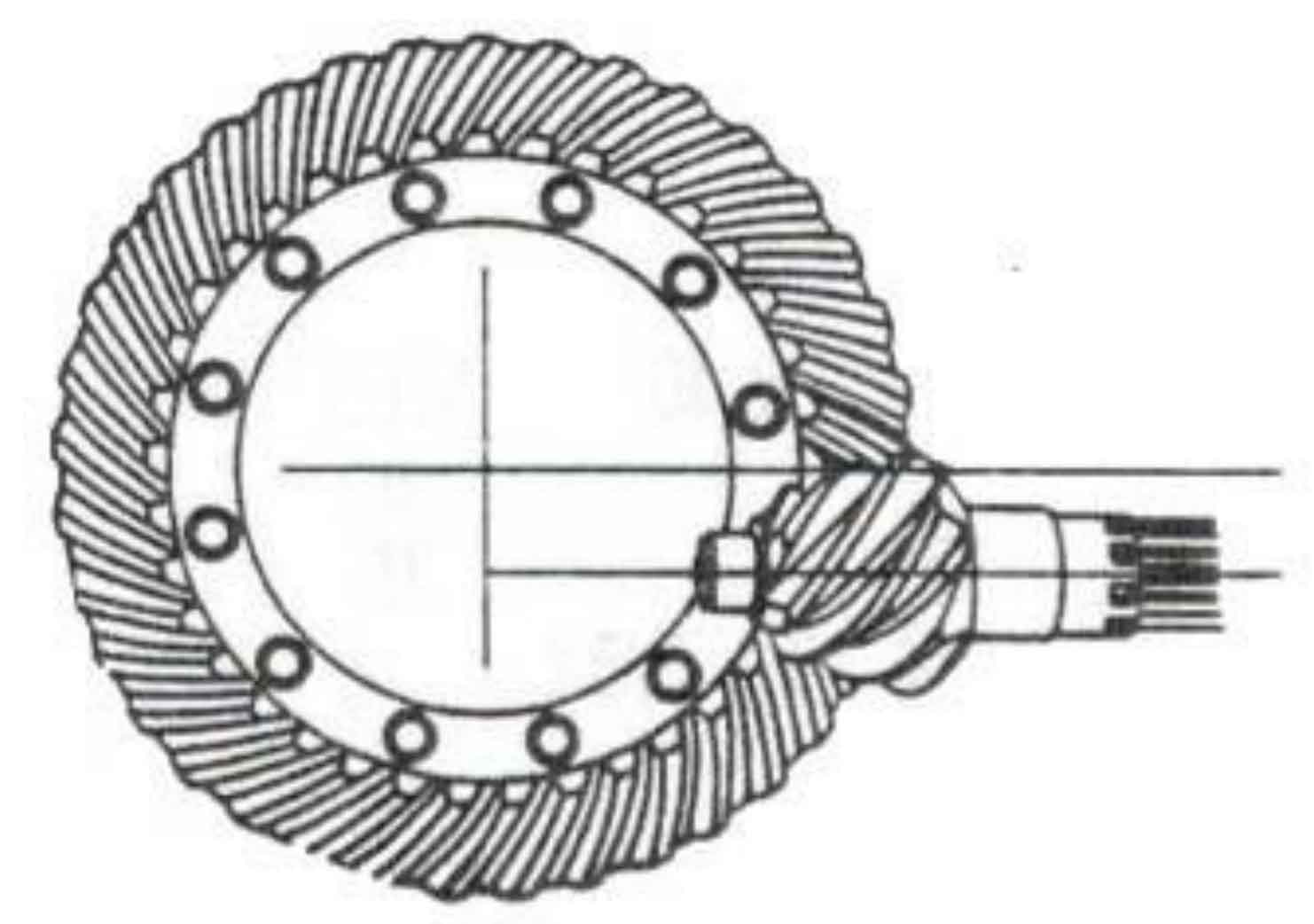

From the above research status, it can be seen that in the meshing analysis of spiral bevel gear or hypoid gear, because the accurate three-dimensional model of hypoid gear cannot be obtained, the test method is the only more accurate method in product design. Researchers have found that there is a large gap between the traditional stress calculation formula and the test measured value for hypoid gears. When designing gears, the results obtained by relying on tests and formulas are different. It is difficult to generalize the test results of a gear to the design of gears of other sizes, which may sometimes lead to overly conservative gear design, and the test is time-consuming and laborious. The research shows that the contact and bending stresses of meshing gears can be obtained by finite element method. Parallel shaft gears (such as involute gears) have analytical solutions to determine the tooth surface coordinates, and these coordinate values can be input into the finite element analysis software. However, for hypoid gears, there is no explicit formula to express the tooth surface coordinates, and it is difficult to establish an accurate mesh finite element model of hypoid gears. Therefore, it is necessary to study the geometric modeling method and meshing performance of hypoid gears.