1. Present situation of spur gear machining

The processing method of face gear is similar to that of ordinary cylindrical gear, mainly including the following three processing methods:

(1) Gear shaping machining gear shaping machining is the most basic and simplest method of face gear machining. The gear shaping machining of face gear uses the generation principle to form the backlash free meshing motion between the gear shaping cutter and the machined gear. F. L. Litvin made a lot of introduction to this similar machine tool equipment. Sandro Barone et al simulated and realized the spur gear by using the machining simulation function of Pro / E Virtual machining of tooth surface. The first table gear shaper in China was successfully developed by Nanjing University of Aeronautics and Astronautics, and the machining of face gear was realized on the shaper. The gear shaping processing of face gear is shown in Figure 1.

(2) Gear grinding and grinding wheel dressing method the application of gear grinding technology can improve the allowable contact strength of hard tooth surface gear and make it applicable to aviation transmission system. A face gear grinding machine has been invented successfully by Ken beel. Its feature is that the angle of workpiece rotating shaft can be well adjusted and can grind non orthogonal face gears with arbitrary cone angle. The machined face gear is also suitable CNC gear grinding machine can be used for processing, which is proposed by crown gear company in the Netherlands. The company is mainly engaged in the research and development of non orthogonal gear grinding machine. The precision of the grinding machine is very high, and its precision can reach agma11-12. At present, in terms of international gear grinding, Boeing company of the United States and North Star Company of Canada have jointly developed a face gear 5-axis grinder, which is the biggest progress in face gear grinding. The grinder can grind face gears with different cone angles and large size range, which can meet the requirements of aviation use. It can produce face gears and pinions with accuracy up to agma12. The outer radius of face gears ranges from 200mm to 500mm, and the shunt transmission verification machine with 2822 HP has also been successfully developed. The research group of Professor Zhu Rupeng of China Southern Airlines is to study the singularity of the tooth profile of the basic worm of the face gear hobbing cutter.

(3) Hob for generation crown gears, a patent document applied by E. Miller of the United States in 1942 The idea of machining face gear with hob is put forward. The main idea of the patent is that the hob helical surface can be processed by the tool with involute cross section through the method of generating motion, but the tooth surface shape of the face gear obtained by gear hobbing is at least 40 ~ 50 microns different from the theory, and the accuracy can not meet the requirements. At the international power transmission and gear conference in 1992, Ishii et al. Also proposed to use NC Hobbing Machine to process face gear. In this method, “flying cutter” is used to replace the special hob, which reduces the cutting force and improves the tooth surface accuracy. However, the tooth profile of face gear machined by this method is different from that obtained by gear shaping. Crown gear of the Netherlands also proposed the method of NC gear hobbing to process face gear, as shown in Figure 2.

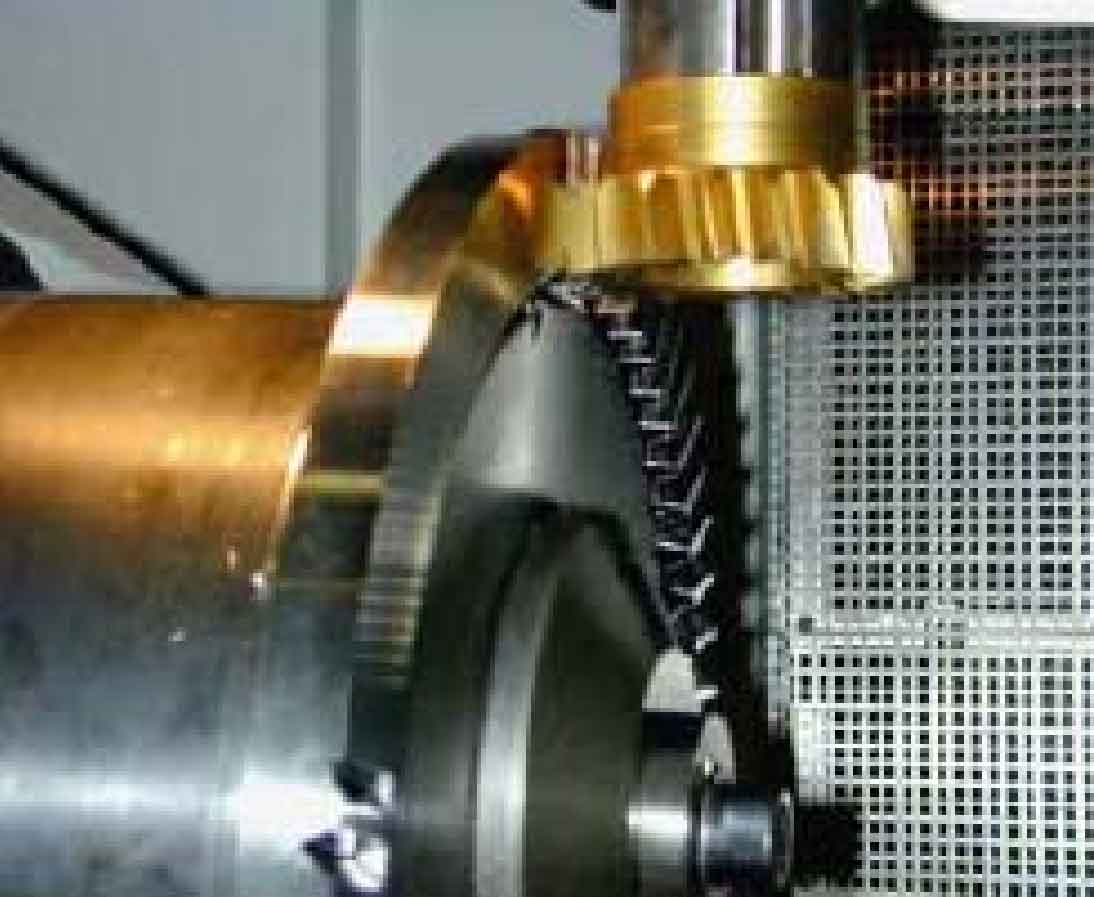

The greatest achievement in the practical application of face gear hobbing technology at this stage is the gear hobbing method of face gear used in aviation transmission accessories. This method adopts cylindrical gear hob and bevel gear hobbing machine with one circle of helix. The width and relative diameter of face gear teeth must be very small, so the strength is low, and can only be used in unimportant occasions. According to the data, now the team led by Professor Wang Yanzhong of Beihang is studying gear hobbing, and relevant results have been achieved in the design of basic worm of face gear hob in 2009. In terms of gear hobbing, Zhao Yingbin of Liaoning University of technology completed the gear hobbing of spur gear last year, as shown in Figure 3.

2. Present situation of helical gear processing

Professor Liu Guanglei of Northwest University of technology has made preliminary theoretical achievements in the study of two parameter method of helical gear worm grinding wheel grinding. A master’s thesis of Northwest University of technology studies the gear shaping machining of helical gear. The core content of its research is: starting from the gear shaping machining principle, using the combination of VB language and AutoCAD software, secondary develop the corresponding program language to simulate the gear shaping machining process of helical gear. Referring to the relevant domestic data of helical gear, it can be seen that the hobbing processing of helical gear in China has not been found.