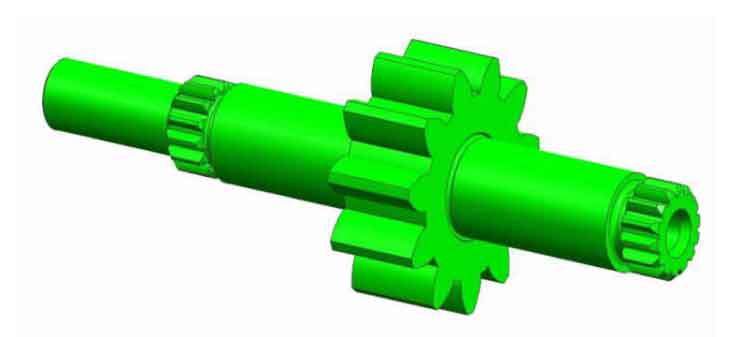

The main function of the gear shaft is to support rotating parts, achieve rotary motion and transfer torque and power. Gear shaft has a series of advantages, such as high transmission efficiency, compact structure, long service life and so on. It is one of the important parts in the general machinery, particularly the engineering machinery transmission. The optimization of the gear shaft’s machining materials, thermal treatm -ent method and machining process will have great significance on the machiningqual -ity of the gear shaft and the service life. This paper discussed the machinery manufa- cturing process planning and fixture design of milling key of a “gear shaft” provided by a enterprise. As for process planning and fixture design, there were two different plans for selecting the better one. The paper firstly analyzed the function of the gear s -haft and its mechanical properties, and then planned the machining process, finally, the fixture design. As gear shaft requires the higher machinery comprehensive properties, we usually select the forgings as the forging blank.

While supporting rotating parts is one of the primary functions of a gear shaft, it serves several other crucial purposes in various mechanical systems. The main functions of a gear shaft include:

1. Power Transmission: Gear shafts play a vital role in transmitting power from the driving element (e.g., motor or engine) to the driven element (e.g., gear, pulley, or sprocket). The gear shaft rotates, and its engagement with other gears or components enables the transfer of rotational motion and torque.

2. Load Bearing: Gear shafts are designed to withstand the mechanical loads and stresses imposed during operation. They support the weight and forces acting on the rotating parts connected to the shaft, ensuring the system’s structural integrity.

3. Motion Conversion: In mechanical systems with multiple components, gear shafts can convert rotational motion into linear motion or vice versa, depending on the arrangement of gears, pulleys, or other mechanisms.

4. Speed Adjustment: Gear shafts, when used in gear systems, allow for speed adjustment and gear ratio changes, enabling precise control of rotational speeds and torque levels.

5. Synchronization: In some applications, gear shafts are used to synchronize the rotation of different components or machines, ensuring proper timing and coordination.

6. Direction Change: Gear shafts, especially in bevel gear systems, change the direction of rotational motion, allowing for the transmission of power between shafts that are not parallel.

7. Support and Alignment: Gear shafts serve as a support structure for other components, aligning them correctly to ensure proper gear meshing and smooth operation.

8. Torque Amplification/Reduction: Gear shafts with different gear ratios can amplify or reduce torque, making them essential for adjusting the output torque to match specific requirements.

9. Versatility and Adaptability: Gear shafts are used in various applications across different industries due to their versatility and adaptability to a wide range of mechanical systems.

10. Mechanical Interlock: In certain mechanisms, gear shafts provide a mechanical interlock, preventing the unwanted movement of certain components during specific operations.

In summary, gear shafts are essential components in power transmission systems and mechanical assemblies. They play a fundamental role in supporting rotating parts, transmitting power and motion, adjusting speed and torque, and ensuring proper coordination and synchronization within mechanical systems. The design and material selection of gear shafts are crucial to ensuring their reliable performance and longevity in demanding applications.

It is very important for ensuring the processing quality of the gear shaft to arrange the process route reasonably anddivide the processing stage. Using Fixture can reduce the auxiliary time, increase productivity, ensure machining accuracy, stabilize the processing quality, reduce the technical requirements for workers and expand the technology range of machine tool. The subject is designed to gear design and gear machining process design. First, to design the gear according to conditions, then the gear design process, and to determine the overall layout design, then, for hobbing fixture design.