Overview of

30Cr2Ni4MoV is a heavy quenching and tempering steel, which contains carbon

The amount is generally between 0.3% and 0.6%, which belongs to medium carbon steel.

When used to make parts, the comprehensive performance of the material is very

Excellent, gear with very good strength, its plasticity and toughness are very good.In the process of engineering construction and manufacturing, the commonly used heat treatment method is the temperature control method. The quality and tempering treatment enable the steel to obtain good mechanical comprehensiveness Yes, gear so this type of steel is often referred to as quenched and tempered steel. Quenched and tempered steel is often Used in large components and structural parts.

The quenching process generally produces martensite in the quenched steel,

500 ~ 650℃ tempering heat treatment After the quenching and tempering heat treatment, the steel obtains good material properties. Good,gear with good strength, plasticity and toughness, that is, excellent comprehensive performance. In manufacturing, Cr Mn quenched and tempered steel (including

including 42CrMo and 40CrMn), chrome quenching and tempering steel (including 40CrSi

and 40Cr),gear chrome-nickel quenching and tempering steel (including: 40CrNiMo and 37CrNi3A) and boron-containing quenched and tempered steel.

The characteristic of quenched and tempered steel is that its carbon content is roughly in the range of 0.3% to 0.5%, and it contains one or more alloying metals.The alloy elements in the steel are mainly used to improve the hardenability of the steel and allow for Components made of high-quality steel can be well machined after high-temperature tempering. Mechanical properties. gear The heat treatment process of quenched and tempered steel is the material’s ability to exceed Heating and quenching within a certain temperature range of the critical point Martensite is obtained, gear and the temperature is completed within the range of 500℃ to 650℃ Tempering, the metallographic structure obtained after heat treatment is tempered sorbite. This organization has good strength, plasticity, and toughness.

Alloy quenched and tempered steel is widely used in various manufacturing industries, especially

In vehicle manufacturing, including automobiles and tractors. In addition, application equipment

On the machine for making beds and parts, gear such as some bolt fasteners, gear sizes

Gears, connecting rods, bearings, etc. The mechanical properties of quenched and tempered steel can withstand multiple The working load requirements are different, and the effect of force action is more complex. The requirements for the hardenability of parts and components vary depending on their stress requirements.Among the quenched and tempered steel, there are various types of carbon steel, including 30#Steel, 35# steel, 40# steel, 45# steel, ML30# steel, ML35# steel, ML40

Steel, ML45# steel, at room temperature, the mechanical properties of steel are stable, large

Used for small and medium-sized structural steel parts, gears, fasteners, shafts, etc.

The steel grades of steel include 40Mn2 steel and 50Mn2 steel. The material characteristics of manganese steel are High temperature tempering embrittlement, thermal sensitivity, and easy water quenching

Cracking, higher hardenability than carbon steel. Silicon-manganese steel is generally used

35SiMn and 42SiMn materials, which have significant tempering High brittleness, decarburization, thermal sensitivity, and fatigue stress.gear Applicable to the manufacturing of medium-speed products with less impact, such as bearings and linkages rods, rotating shafts, etc. In addition, this material can be used to manufacture products with a temperature lower than 400℃ studs and other components.

The types of boron steel include 40B, 45B, 50BA, and ML35B. This type of steel has good hardenability and comprehensive mechanical properties, Better than carbon steel, this type of steel is similar to 40Cr and is used in small parts In the manufacturing of parts and fasteners, such as nuts and studs, the steel of manganese boron steel The material is 40MnB, which has higher hardenability than 40Cr material.

Low temperature impact toughness and tempering brittleness. The steel grades of manganese vanadium boron steel are 20MnVB steel and 40MnVB steel,gear which are characterized by higher tensile strength compared to 40Cr. It has good tempering characteristics and hardenability, and has a tendency to overheat Small, in addition to having a certain degree of temper brittleness. Used for manufacturing and processing important The steel grade of the quenched and tempered parts is 40MnWB, which is a steel grade of manganese tungsten boron steel. The impact resistance is good at low temperatures, and the material has no tempering brittleness.gear This steel The performance is close to that of 35CrMo and 40CrNi, and it is generally used at a temperature of no higher than 65 mm parts are being manufactured. The types of silicon-manganese-molybdenum-tungsten steel are 35SiMn2MoW, with high hardenability, low tempering brittleness, gear and Very low cracking; high strength and toughness. Used for load bearing and cross-sectional areas Relatively large rotating shafts, rods, and fasteners.

The steel grade 37SiMn2MoWVA has good low-temperature impact toughness and tempering stability, as well as high high-temperature strength. The temper brittleness is small. The most common types of chromium steel are 40Cr and ML40Cr, with good hardenability, water quenching at 30-55mm left

Right, its oil quenching is between 20 and 40 mm, and its mechanical properties are relatively

Good, in addition,gear it has good low temperature impact toughness. It is commonly used in teeth

In the manufacturing of wheels, shafts, rods, and fasteners, the steel grades of chromium-silicon steel include 38CrSi, which has a higher hardenability than 40Cr. Chromium-molybdenum steel is generally

30CrMoA, 42CrMo, ML30CrMo and ML42CrMo, which have high strength The degree and mechanical properties are very good, and the material has good low-temperature impact resistance. High impact resistance, gear no temper brittleness.

Chromium-nickel-molybdenum steel is generally 40CrNiMoA, with comprehensive mechanical properties such as high strength, good ductility, and excellent corrosion resistance.Good, with high low-temperature impact toughness, gear low notch sensitivity and no Tempering brittleness, commonly used in the manufacture of large crankshafts, gears, and fasteners. Chromium Nickel molybdenum vanadium steel is generally 45CrNiMoVA. The strength and tempering stability of the material It is characterized by good quality and is often used in the manufacturing of heavy-duty automobile shafts. 30Cr2Ni4MoV is a common alloy in the machinery industry.One of the high-quality steels, gear this steel has a moderate carbon content and contains various alloying elements,It contains high alloy content such as Cr, Ni, Mo, V, etc., and has high hardenability. Good, high mechanical strength. 30Cr2Ni4MoV steel is quenched and tempered

After tempering, due to its high hardenability, the microstructure is composed of tempered sorbite groups Good comprehensive mechanical performance, in the current manufacturing industry,

Its use is quite extensive,gear mainly for the production of gears, various shafts and rotor components, especially for the manufacture of large sections,gear high negative Forging pieces that bear load and impact load. The article mainly studies Chemical element optimization and forging of 30Cr2Ni4MoV forgings Manufacturing methods and heat treatment methods for tempering of materials forging

Influence of microstructure on mechanical properties of 30Cr2Ni4MoV steel The impact of energy.

Manufacturing process of forgings

The forging is made of steel ingot with VOD refining of 6T ingot type. Due to the

Alloyed quenching and tempering steel contains various alloying elements such as Cr, Ni, Mo, etc.

The composition of its elements is relatively complex,gear and gear forgings are used as power transmission The mechanical properties required for toughness are very important. Therefore, steel

During the smelting of ingots, the composition should be optimized and adjusted reasonably

The percentage of chemical elements in the ingot should be increased due to the high strength required.

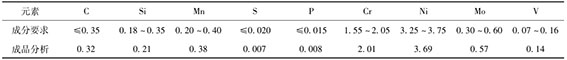

Increase the content of alloy elements in the material, and choose Cr and V according to the composition requirements The upper limit, its working environment is more demanding, which increases the Ni and Co content of the material. The content of Mo element, which improves the corrosion resistance of the material, is increased through High alloy element content to improve the mechanical properties and usability of the product Yes. After component optimization,gear VOD refined 6T ingot is detailed

The chemical element composition analysis is shown in Table 1. The selected ingots were subjected to

The hot forging of 5000T oil press is controlled at the initial forging temperature of

1185℃±15℃ range, after 3000 tons of oil press is used to break up the billet, it is sent to

After forging, the forging is pre-treated with 900°C×6H normalizing.

Forging process of forgings

The gear forging is subject to relevant thermal forming on a 3000-ton oil press. Due to the large size of the forging, the forging process of forging and forming Necessary forging process control should be adopted to control the beginning and end of forging Forging temperature (starting forging temperature: 1185°C,gear final forging temperature: 800°C) and forging ratio of each heat forging. The ingot is heated in an electric heating furnace When the temperature reaches 1185℃, the holding time is 6-7 hours, and the ingot is properly After preheating, the subsequent high-temperature heating is carried out, followed by forging out of the furnace.

Physical and chemical inspection of forging products

After the forging undergoes performance heat treatment, a test ring is cut from the forging.gear

The sampling location is on the outer cylindrical end surface of the pie-shaped forging, as shown in Figure 6. Metallographic The sample size is 15×15×15, and the tensile test bar is made of straight steel.

The standard test bar with a diameter of 10mm and a gauge length of 50mm is used. The impact test uses a V-notch specimen for Charpy impact testing. Using a Nikon LV150N microscope to observe the material organization The mechanical properties tensile testing machine used is WDW-100D, and the Charpy impact testing machine model is JB-300B. After the completion of the test and impact toughness test, the experimental results are analyzed. Analyze the situation.

The microstructure photo of the forged piece after tempering heat treatment, taken from the The microstructure on the film is easy to see, and after heat treatment, After heat treatment, gear the microstructure of the forging is tempered sorbite. The organization shows high toughness, improving the use of gear components. Use performance.

The measured properties of the gear forging after tempering, the results It is shown that after the forging is subjected to quenching and tempering treatment, the forging room temperature mechanical tensile and impact The toughness fully meets the technical specifications of the product, and the tensile and impact strength are high.gear The margin is large and the impact value of the material is relatively uniform, indicating that the material matrix has good mechanical properties.The learning performance is relatively uniform and stable.

Conclusion

Composition of 30Cr2Ni4MoV material after preliminary metallurgical process Proportion optimization, forging control process of forging during the forging process, and forging Overall forging ratio and final fire-time molding process control, which provides and laid a solid foundation for the excellent quality of the forging. After the forging is completed,By adopting a reasonable heat treatment system, the mechanical properties and microstructure of the forged piece are optimized, and the mechanical properties of the final forged product are not only fully Meet the technical requirements and indicators, and the mechanical strength and toughness impact of the forging The forging has a large amount of work and is optimized for mechanical property testing. The results showed that the forging had high performance data, good toughness, and relatively uniform microstructure. The overall mechanical properties of the forging are improved, resulting in better product performance. The safety and service life have been improved to a certain extent,and also provide certain technical data reference for the manufacturing process of this type of material.Take the exam.