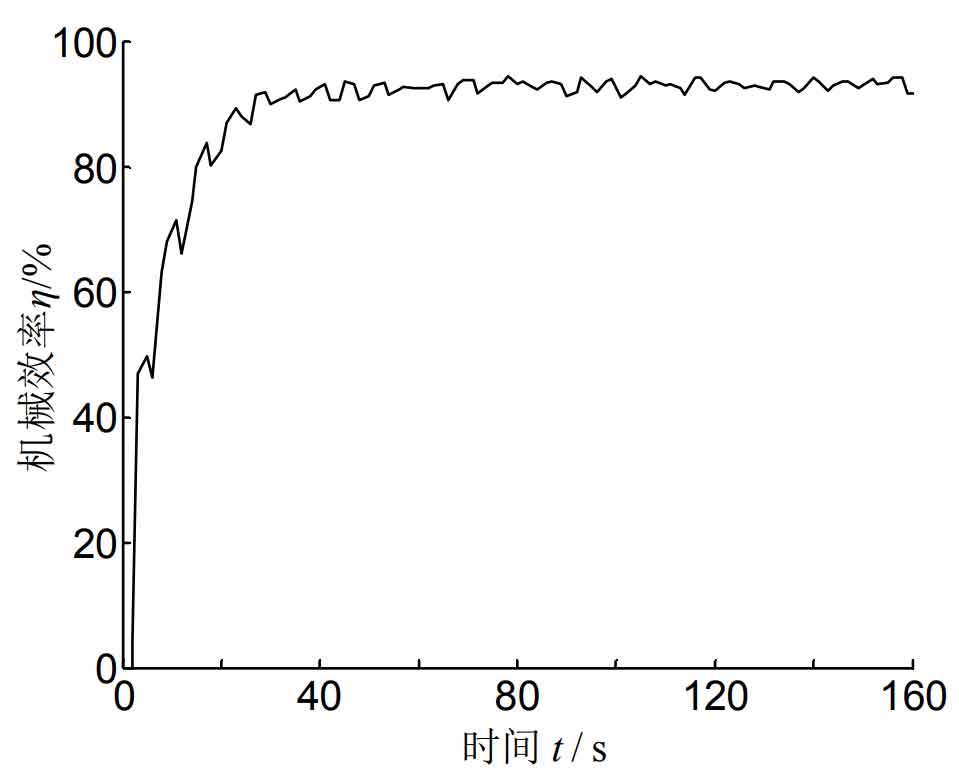

The variation law of actual speed and torque can reflect the approximate meshing characteristics of spiral bevel gears. In order to obtain more accurate meshing performance parameters, the change laws of main meshing performance parameters such as transmission efficiency and transmission error of spiral bevel gear transmission are obtained by using the data processing function of computer. Fig. 1 and Fig. 2 respectively show the variation law of transmission error and mechanical efficiency of spiral bevel gear transmission.

As can be seen from the transmission error curve in Figure 1, the transmission error of spiral bevel gear is relatively small, and the fluctuation range is about 0.1rad. The finite element analysis does not consider the installation error of bearings, couplings and other structures and the impact of friction on the transmission, which may cause the analyzed transmission error to be smaller than the test measurement error. The transmission errors obtained from the finite element analysis results and the experimental measurement results are small. Again, it shows that the spiral bevel gear transmission is stable and has high transmission accuracy.

The variation curve of mechanical efficiency in Figure 2 gradually increases to about 94.0%, and its fluctuation range is small, indicating that spiral bevel gear has large mechanical efficiency; In the start-up stage, friction, damping and other factors may have a great impact on the input and output power of spiral bevel gear; With the increase of speed and torque, the influence effect is weakened, resulting in the phenomenon that the mechanical efficiency gradually increases in the starting stage.