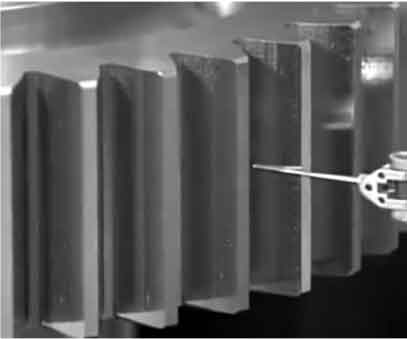

Because the gear tooth surface roughness is affected by many factors, the results obtained from different tooth surface measurement directions and positions are also different. In order to compare the roughness differences along the tooth profile direction and tooth direction, 20 20CrMnTi gear specimens are selected to measure the roughness values at the tooth top, indexing circle tooth surface and tooth root in different directions by needle drawing method, as shown in Fig. 1 As shown in Figure 2. The mean value is calculated and the roughness value curve is drawn.

By analyzing the measured tooth surface roughness data, it can be obtained that the average roughness Rz measured according to the tooth profile direction varies from 4.9527 to 6.1836 μ m. The variation range of roughness mean RZ measured according to the tooth direction is 1.2461 ~ 1.8720 μ m. Obviously, the measurement results along the tooth direction are better than those along the tooth profile direction. Because the curvature of the root position of the tooth groove along the tooth profile direction is small, the measuring point is easy to exceed the measuring range of the instrument, so the tooth direction is used to measure the tooth surface roughness of gear hobbing in subsequent experiments. According to the experimental data, the change curve of the roughness value measured in the tooth profile direction and the tooth direction shows a certain linear relationship, as shown in Fig. 3.