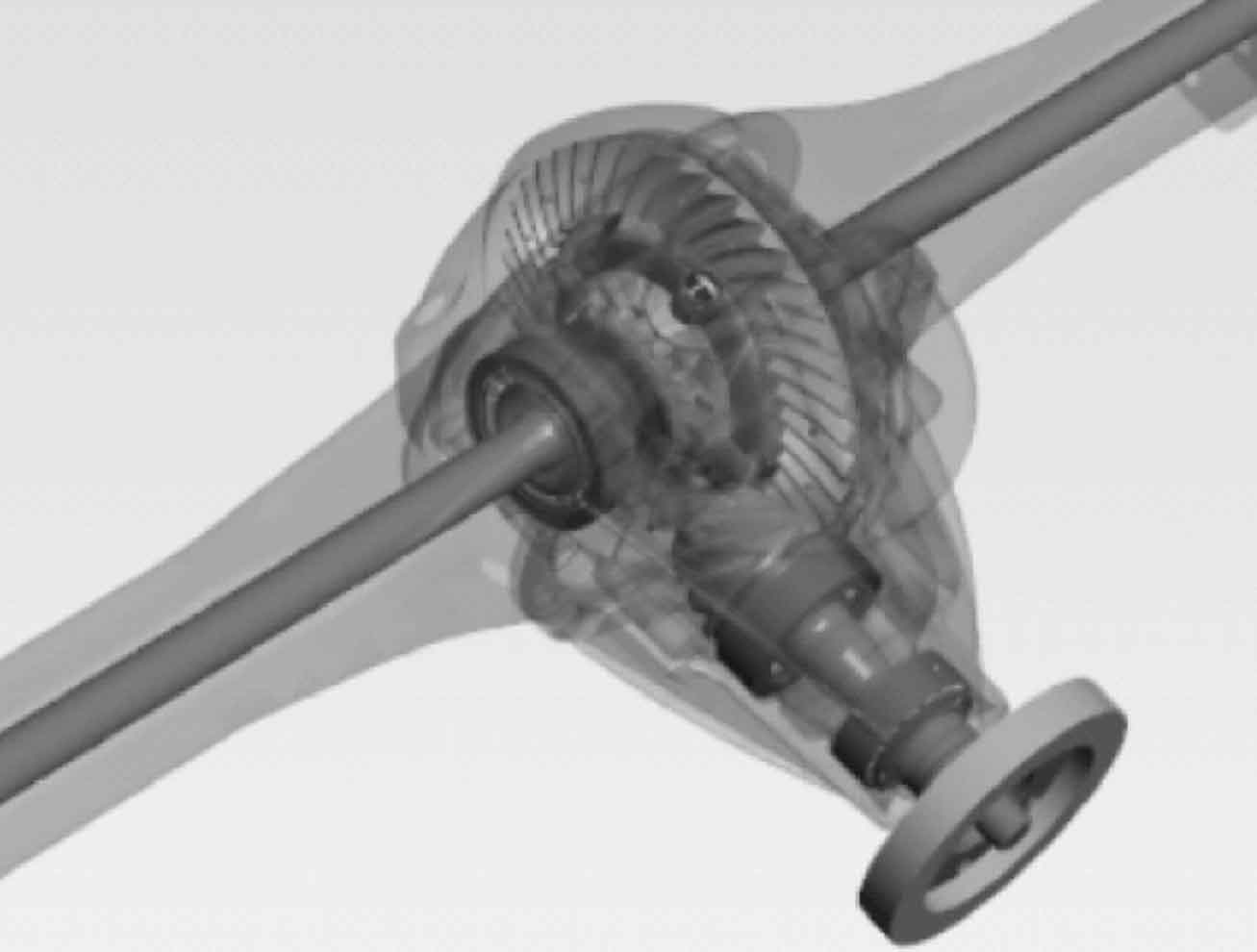

The installation position of hypoid gear in the drive axle transmission system is shown in Figure 1. The hypoid gear is first installed in the main reducer housing, and then the whole main reducer is installed on the drive axle housing.

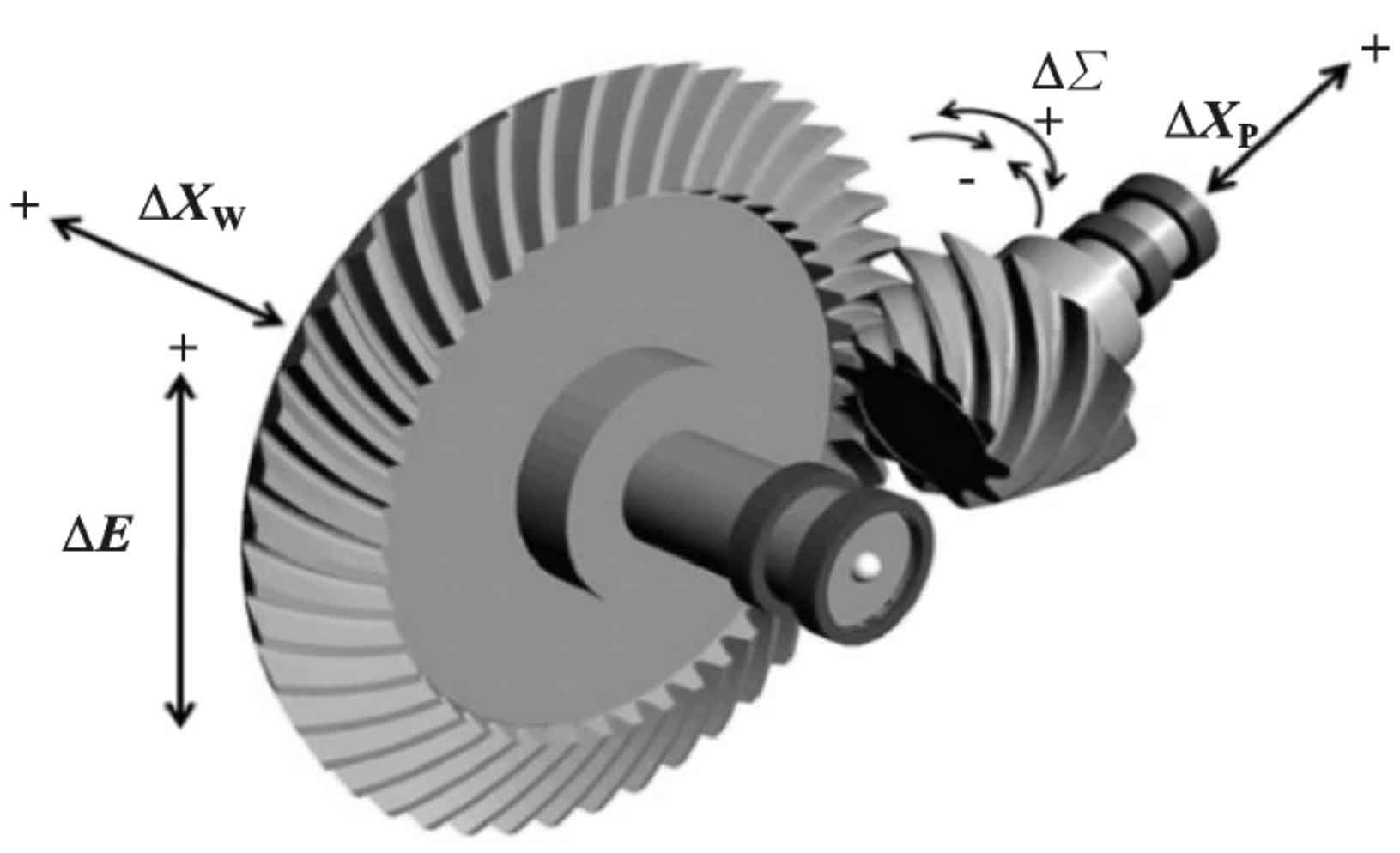

Under actual working conditions, when the hypoid main reducer gear bears load, the force between the tooth surfaces will be transmitted to the support bearing of the hypoid main reducer gear, so as to offset the relative installation position between the small wheel and the large wheel. These offsets are called meshing misalignment of hypoid gears, as shown in Figure 2. In the figure, Δ XP is the axial misalignment of the small wheel, Δ XW is the axial misalignment of the large axle, Δ E is the vertical displacement of the small wheel axis relative to the large wheel axis, ΔΣ Is the included angle misalignment of hypoid gear shaft.

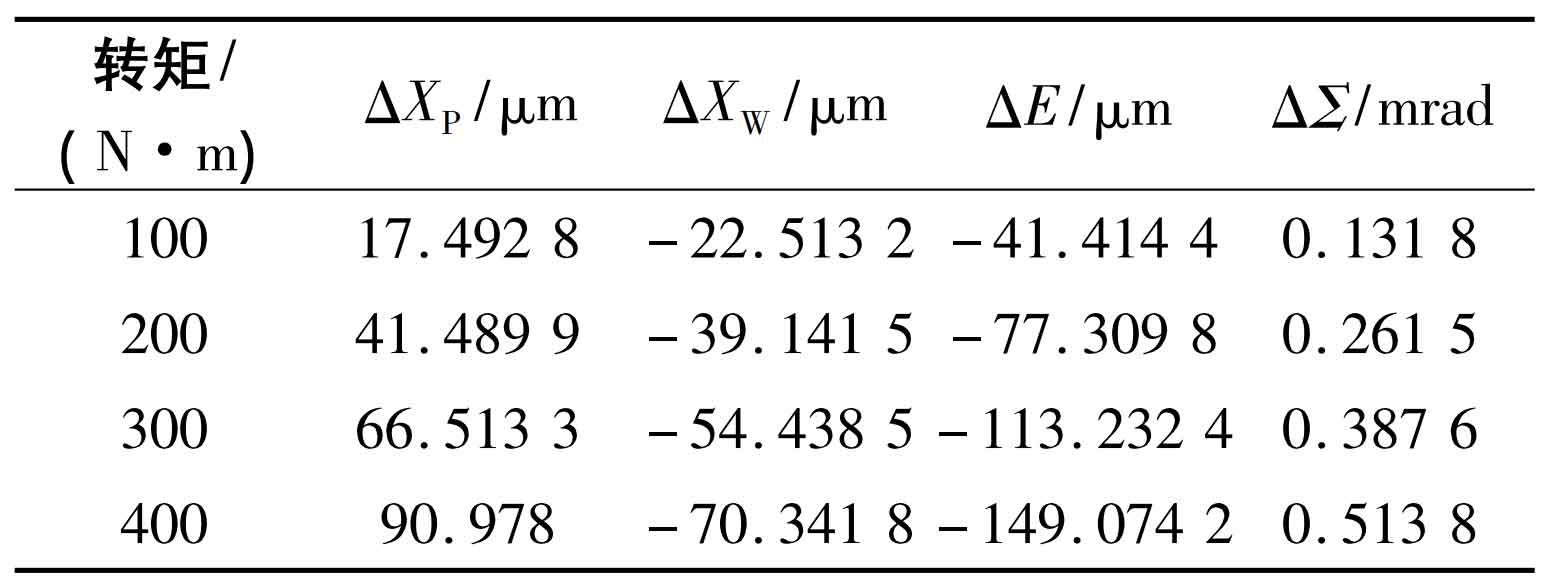

With the help of the deformation analysis function of Masta software system, the meshing misalignment of hypoid gear under actual working conditions is calculated, and the meshing misalignment data of hypoid gear under four loads are given in the table.