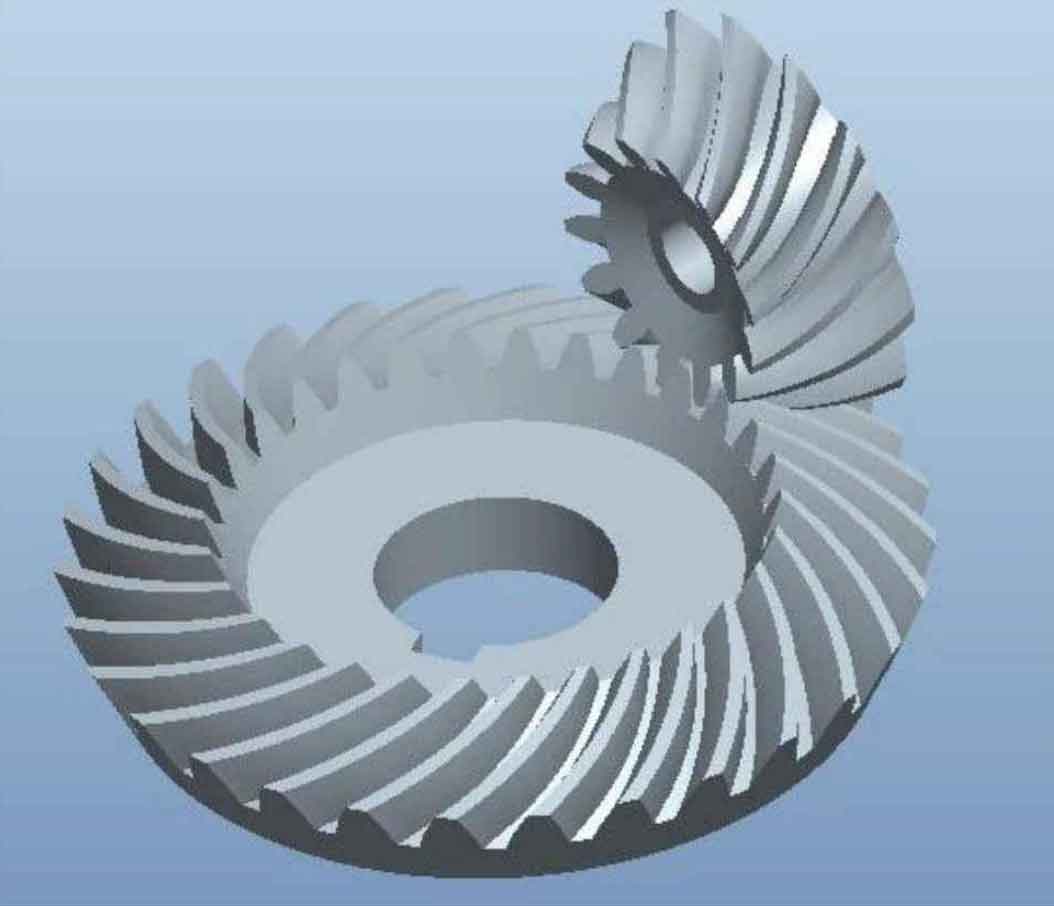

From the research status of hypoid gear or spiral bevel gear transmission error at home and abroad, it can be seen that using the finite element method to analyze the gear load transmission error (LTCA) can accurately reflect the real working state of the gear, but there is no detailed research on the influencing factors of gear dynamic transmission error, such as the input load condition and the influence of gear installation deviation. Therefore, the load transmission error analysis model of hypoid gear is established based on the finite element method, and the influencing factors of transmission error are compared and analyzed.

Another time-varying dynamic meshing feature of drive axle hypoid gear is meshing stiffness. The elastic bending deformation of gears and the change of contact number of meshing gears will cause the change of meshing stiffness of gears. The excitation of time-varying meshing stiffness will cause instability and violent vibration of gear transmission system. A large number of tests have proved that large meshing impact will lead to large vibration of the system. Wang Lihua and frolov have concluded that the change of meshing stiffness caused by transmission error is the main reason for the noise and vibration of gear system, and the base pitch deviation and tooth profile deviation will also cause the noise and vibration of gear system.

Abroad, in the research of meshing stiffness of hypoid gears, teik C et al. Established a multi degree of freedom model of quasi double sided gear meshing, and used a constant constant and trigonometric function to approximate the gear meshing stiffness. In 2002, Lin J and Parker R G studied the change of vibration parameters of the system caused by the change of meshing stiffness of the planetary gear system. Due to the continuous change of contact conditions in the multi tooth meshing process of the planetary gear system, the meshing stiffness of the gear changes constantly. The meshing stiffness between the sun gear and the planetary gear, as well as between the planetary gear and the ring gear is simulated by a square wave. In 2014, S Theodossiades et al. Obtained the time-varying meshing stiffness of hypoid gears through the professional finite element software calyx, simplified the meshing stiffness of gears into Fourier series form, and finally obtained the empirical formula of meshing stiffness of gears.

In China, in 2008, bu Zhonghong and others first obtained the tooth surface flexibility coefficient through finite element software, and then used the proposed linear programming method to calculate the meshing stiffness of spur gears. In 2010, bu Zhonghong and others used the same method to calculate the meshing stiffness of helical gears and studied the change law of meshing stiffness. In the same year, Fang Zongde established a dynamic meshing model of hypoid gears according to the static stress state during gear meshing, but this model did not take into account the time-varying characteristics of gear meshing stiffness in the process of gear meshing. In 2014, Tang Jinyuan and others calculated the meshing stiffness of a single tooth from the basic theory of gear stiffness, and then obtained the meshing stiffness of multiple teeth when meshing at the same time from the superposition of a single tooth. This model ignored the influence of the direction of gear meshing force changing with the rotation angle of the gear in the process of hypoid meshing. In 2015, Sun Hong and others used the principle of equivalent meshing error to convert the manufacturing error and installation error of gears to the meshing line, established the vibration coupling model of gear system by using the method of motion lumped parameters, calculated the dynamic load coefficient of spur gear transmission system, and analyzed the influence of error and gear meshing stiffness on the dynamic load coefficient of gear transmission system. In 2017, Chang Lehao et al. Based on the Smith slice method theory, the helical gear was divided into a series of independent thin spur gears along the tooth width direction. Considering the bending shear deformation, local contact deformation and wheel body structure deformation of a single slice, the nonlinear bearing contact model of the helical gear was established through the deformation coordination relationship between the slices, and then the load distribution, transmission error and meshing stiffness of the tooth surface were obtained.

According to the above analysis, the corresponding calculation methods for the time-varying meshing stiffness of hypoid gears have been proposed abroad, but the specific calculation details have not been disclosed, and there are few studies on calculating the meshing stiffness of hypoid gears based on the currently widely used ABAQUS or ANSYS finite element method. In China, there are few models that truly reflect the meshing characteristics of hypoid gears. At the same time, the application of software calyx is less, and it is difficult to establish an accurate geometric model and finite element model of hypoid gears. Therefore, this paper will propose a method based on the general finite element method to calculate the time-varying meshing stiffness of hypoid gears.