(1) Metal flow field during hot extrusion

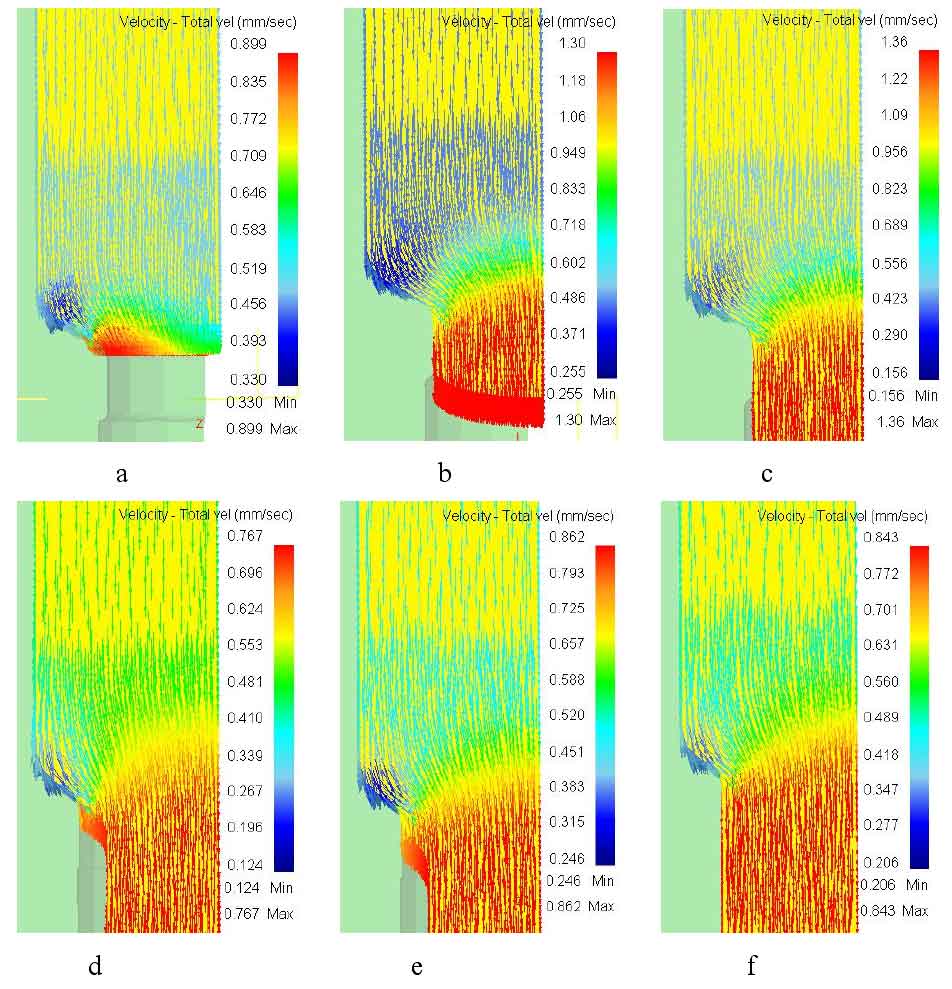

Figure a ~ C in Figure 1 shows the metal flow state at different times when extruding the 31.31mm shaft, and figure d ~ F shows the metal flow state at different times when extruding the 38.89mm shaft. It can be seen that at the beginning of extrusion (figure a), the metal flow velocity at the inner fillet of the die is significantly lower than that at other parts. Affected by the conical angle slope of the die, the metal in the outer layer of the end flows towards the direction below the center slope, and the metal flow velocity in the outer layer of the end is large. With the increase of punch reduction (Fig. b), the metal flow velocity at the fillet of the female die is the smallest part of the deformation area. At this time, the metal flow velocity in each part of the main deformation area has changed. On the same horizontal line, the flow velocity of the inner metal is greater than that of the outer metal, which is due to the influence of the friction resistance of the die. In the deformation zone, the flow of metal is uneven, and the flow of outer metal lags behind that of inner metal. At the end of the 31.31mm shaft forming (Fig. C), the metal flow velocity at the fillet of the die is still the minimum area of the spiral bevel gear blank.

This area is actually the “dead zone” with the worst flow conditions of spiral bevel gear blank when extruding solid parts. However, there is no real non flow of metal, which shows that the design of die cone angle and the selection of fillet size are more reasonable. For the formed part, the metal flow speed and direction remain unchanged, because the formed shaft is no longer subject to plastic deformation, only rigid translation, and the flow speed of this part is the largest, about 1.3mm/s.

It can be seen from the analysis d~f diagram that the metal flow state when extruding the 38.89mm axis is similar to that when extruding the 31.31mm axis. The flow speed of the metal in the fillet of the die is small, but it can maintain normal flow, which can ensure that the metal in this part will not fall off after extrusion. It shows that the design of extrusion 38.89mm female die is also reasonable. The maximum translation speed of the formed shaft is about 0.85mm/s.

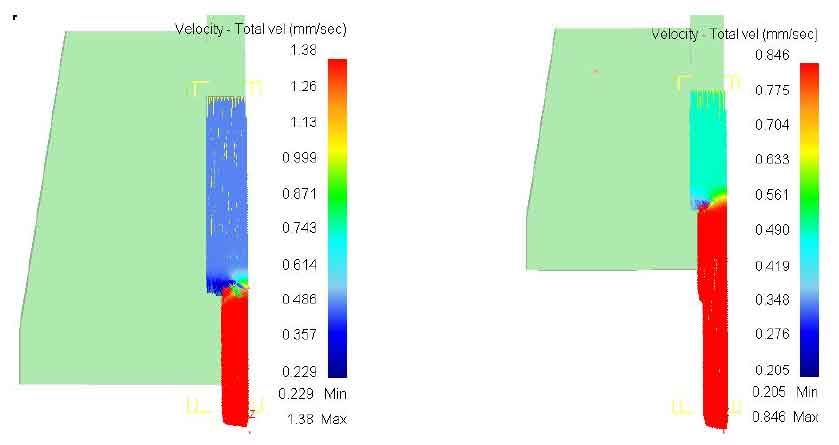

It can be analyzed from the flow state that the deformation in the extrusion process is mainly concentrated near the same horizontal position of the inclined plane of the cone angle of the die. This position is called the severe deformation area. Before entering and after leaving this area, the metal hardly deforms and only makes rigid translation. This rigid translation can be seen more clearly in Figure 2.

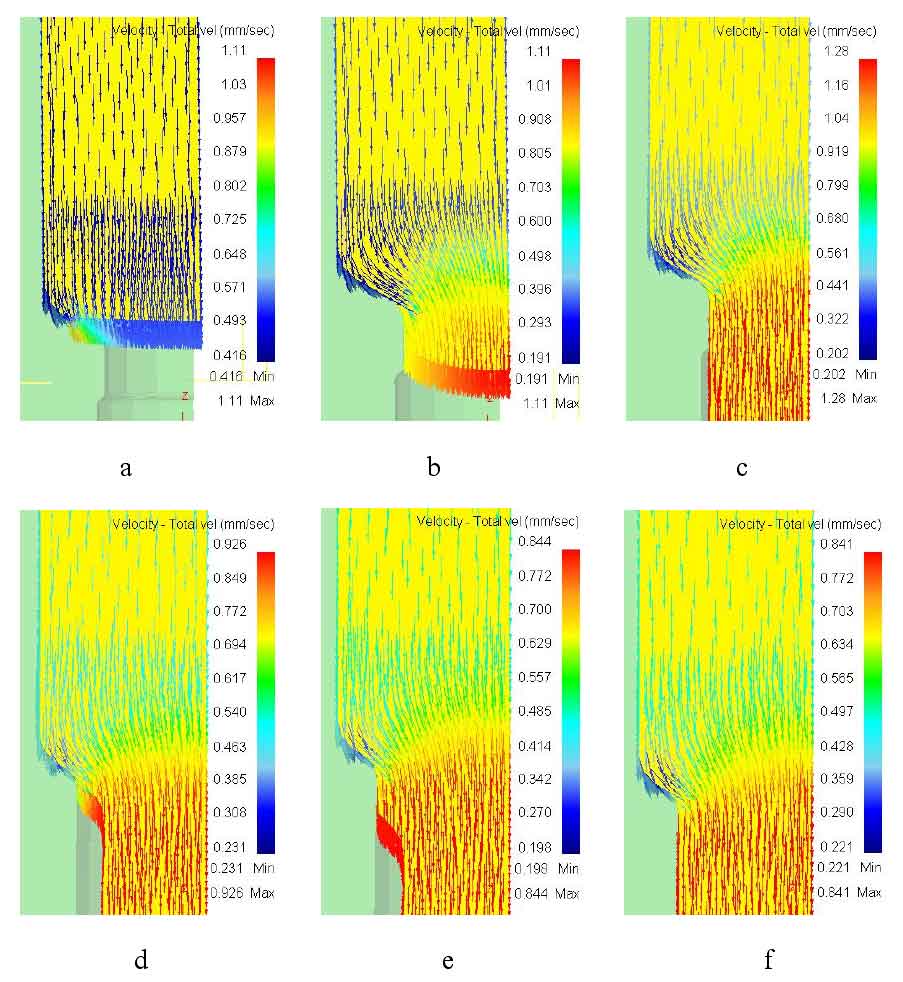

(2) Metal flow field during cold extrusion

Comparing Fig. 3 and Fig. 1, it can be seen that the flow state distribution of metal during extrusion is basically similar, which shows that cold extrusion and hot extrusion do not affect the flow state distribution of metal under the same other conditions. During cold extrusion, under the condition of 120 ° die cone angle, the extrusion rate of “dead zone” metal is lower than that of other parts, but it maintains normal flow. In the severe deformation zone, the metal flow is relatively smooth and reasonable. From the metal flow, cold extrusion forming is completely feasible.

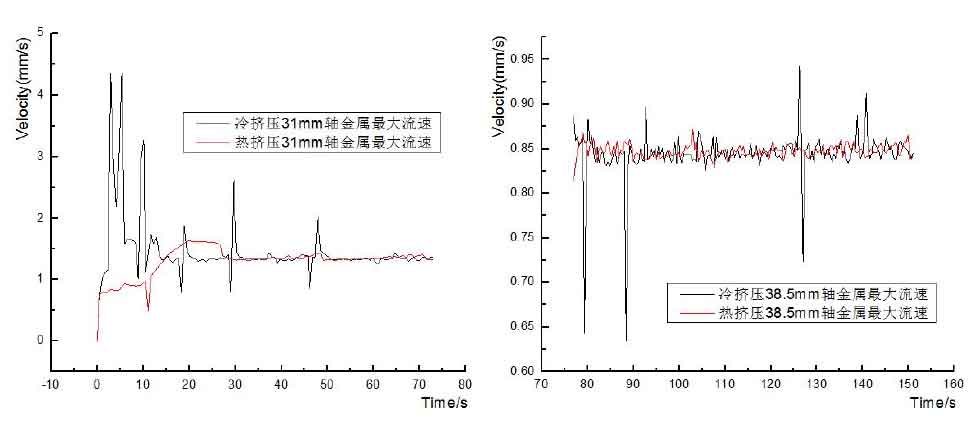

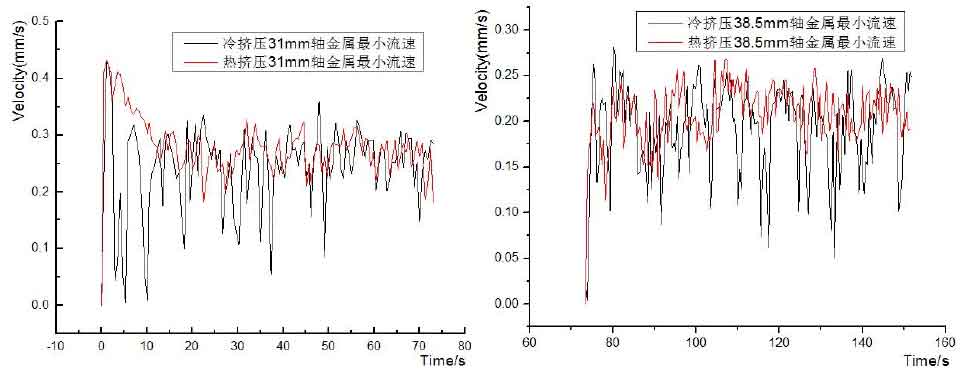

(3) Comparison of metal flow velocity between cold extrusion and hot extrusion

Since the fluidity of hot metal is much better than that of cold metal, it can be seen from Figure 4 that the flow velocity fluctuation of hot extruded metal is small, the flow velocity fluctuation of cold extruded metal is large, and the flow velocity of hot extruded metal is more stable than that of cold extrusion. c. Figure D shows the comparison of the flow in the extrusion “dead zone” during cold and hot extrusion. The comparison of metal flow velocity at this position is more important, and the unreasonable metal flow in the “dead zone” may cause this part of the technology to fall off after extrusion. It can be seen from the figure that during hot extrusion, the flow velocity of “dead zone” metal should be more stable, and the fluctuation is very small, almost no less than 1.5mm/s. During cold extrusion, due to the limited metal flow capacity, the flow velocity of “dead zone” metal fluctuates greatly, and the value of less than 0.1mm/s occurs frequently. However, when extruding 31mm axis and 38.5mm axis, the “dead zone” metal can maintain normal flow state, This ensures that qualified extrusions are obtained.